概要

3D printing, also known as additive manufacturing (AM), utilizes metal powders to construct complex components layer by layer directly from digital models. The powders are selectively melted or bound by precision heat sources guided by the CAD model geometries.

Popular AM processes for metals include binder jetting, directed energy deposition, powder bed fusion, sheet lamination, and more. Each requires powder feedstock with specific characteristics to achieve optimal density, surface finish, dimensional accuracy, and mechanical properties.

This guide provides an in-depth look at metal powders for 3D printing, including alloy types, powder production methods, key powder properties, applications, specifications, suppliers, and purchasing considerations when sourcing material. Helpful comparison tables summarize technical data to assist with powder selection and qualification.

Connecting with knowledgeable suppliers of optimized 3D printing powders enables manufacturers to improve print quality, reduce defects, and fully leverage AM benefits like design freedom, faster iteration, and part consolidation.

Alloys for 3D Printing Powders

A wide range of metals and alloys are available in powder form suitable for AM processes:

Common Alloy Systems for 3Dプリンティング金属粉末

- ステンレス鋼

- 工具鋼

- チタンおよびチタン合金

- アルミニウム合金

- ニッケル超合金

- コバルトクロム合金

- 銅合金

- 貴金属

Both standard and custom alloys can be sourced to meet specific application requirements in terms of corrosion resistance, strength, hardness, conductivity, or other properties.

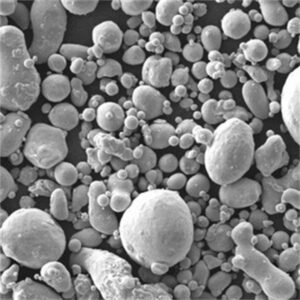

AM用金属粉末製造法

Additive manufacturing utilizes metal powders produced through:

Typical Metal Powder Manufacturing Methods for 3D Printing

- ガス噴霧

- 水の霧化

- プラズマ霧化

- 電解

- Carbonyl iron process

- メカニカルアロイング

- Metal hydriding/dehydriding

- Plasma spheroidization

- Granulation

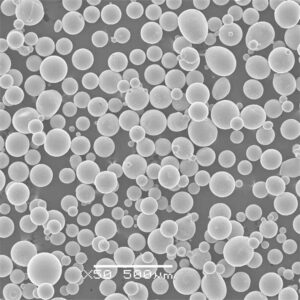

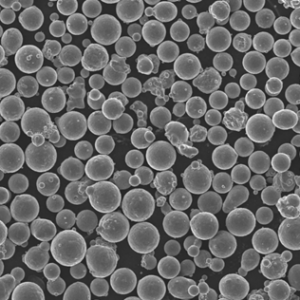

Spherical atomized powders provide optimal flow and dense packing needed for most AM processes. Some techniques allow nanoscale or customized alloy particles.

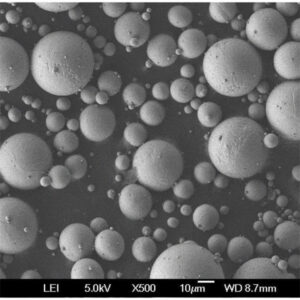

Key Characteristics of Metal Printing Powders

Critical powder characteristics for AM include:

Metal 3D Printing Powder Properties

| 特徴 | 代表値 | 重要性 |

|---|---|---|

| 粒度分布 | 10~45ミクロン | Affects densification, surface finish |

| 粒子形状 | 球形 | Improves flow and packing |

| 見かけ密度 | 2 to 4 g/cc | Influences bed density |

| タップ密度 | 3 to 6 g/cc | Indicates compressibility |

| ホール流量 | 25-50 s/50g | Ensures smooth powder spreading |

| 強熱減量 | 0.1-0.5% | Low moisture improves printing |

| 酸素含有量 | <0.1% | Minimizes microstructural defects |

Precisely controlling characteristics like particle size, shape, and chemistry is critical to achieve fully dense AM parts with the desired mechanical properties.

の応用 3Dプリンティング金属粉末

AM enables complex geometries impossible through conventional techniques:

Metal 3D Printing Applications

| 産業 | 用途 | メリット |

|---|---|---|

| 航空宇宙 | Turbine blades, structures | Design freedom, weight reduction |

| メディカル | インプラント、補綴物、器具 | Customized shapes |

| 自動車 | Lightweighting prototypes and tools | Rapid iteration |

| ディフェンス | Drone parts, protective structures | Quick prototypes and short runs |

| エネルギー | Heat exchangers, manifolds | Part consolidation and topology optimization |

| エレクトロニクス | Shielding, cooling devices, EMI | Complex enclosed structures |

Lightweighting, part consolidation, and high-performance alloys for extreme environments provide key advantages over traditional manufacturing methods.

Specifications for 3D Printing Metal Powders

International specifications help standardize AM powder characteristics:

Metal Powder Standards for Additive Manufacturing

| スタンダード | スコープ | パラメータ | 試験方法 |

|---|---|---|---|

| ASTM F3049 | Guide for characterizing AM metals | Sampling, size analysis, chemistry, defects | Microscopy, diffraction, SEM-EDS |

| ASTM F3001-14 | Titanium alloys for AM | Particle size, chemistry, flow | Sieving, SEM-EDS |

| ASTM F3301 | Nickel alloys for AM | Particle shape and size analysis | Microscopy, image analysis |

| ASTM F3056 | Stainless steel for AM | Chemistry, powder properties | ICP-OES, pycnometry |

| ISO/ASTM 52921 | Standard terminology for AM powders | Definitions and powder characteristics | Various |

Compliance with published specifications ensures repeatable, high quality powder feedstock for critical applications.

の世界的なサプライヤー 3Dプリンティング金属粉末

Leading international suppliers of AM-optimized metal powders include:

Metal Powder Manufacturers for 3D Printing

| サプライヤー | 材料 | Typical Particle Size |

|---|---|---|

| サンドビック | Stainless, tool steel, nickel alloys | 15-45ミクロン |

| プラクセア | チタン、超合金 | 10~45ミクロン |

| エーピーアンドシー | チタン、ニッケル、コバルト合金 | 5~25ミクロン |

| カーペンター添加剤 | Cobalt chrome, stainless, copper | 15-45ミクロン |

| LPWテクノロジー | Aluminum alloys, titanium | 10-100 microns |

| イーオーエス | Tool steel, cobalt chrome, stainless | 20-50 microns |

Many focus on fine spherical powders specifically engineered for common AM methods like binder jetting, powder bed fusion, and directed energy deposition.

Purchasing Considerations for 3D Printing Metal Powder

Key aspects to discuss with metal powder suppliers:

- Desired alloy composition and properties

- Target particle size distribution and shape

- Envelope density and hall flowability

- Allowable impurity levels like oxygen and moisture

- Required testing data and powder characterization

- Available quantity range and lead times

- Special handling precautions for pyrophoric materials

- Quality systems and powder origin traceability

- Technical expertise in AM-specific powder requirements

- Logistics and delivery mechanisms

Work closely with suppliers experienced in optimized AM powders to ensure ideal powder selection for your process and components.

金属3Dプリント粉末の長所と短所

Benefits vs Limitations of Metal Powders for AM

| メリット | デメリット |

|---|---|

| Allows complex, customized geometries | Higher cost than conventional materials |

| Shortens development time dramatically | Powder handling precautions required |

| Simplifies assemblies and lightweights | Post-processing often needed on as-printed parts |

| Achieves properties nearing wrought materials | Size and build volume constraints |

| Eliminates expensive dies, molds, tooling | Thermal stresses can cause cracking and distortion |

| Enables parts consolidation and topology optimization | Lower production volumes than traditional methods |

| Improves buy-to-fly ratio greatly | Requires rigorous powder characterization and parameter development |

When used appropriately, metal AM provides game-changing benefits but requires expertise to implement successfully.

よくあるご質問

How small can metal powder particle size be for AM?

Specialized atomization techniques can produce powder down to 1-10 microns, however most metals printers work best with minimum size around 15-20 microns for good flow and packing.

What causes poor surface finish in printed metal parts?

Surface roughness arises from partially melted powder adhered to surfaces, spatter, staircase stepping, and suboptimal melt pool characteristics. Using finer powders and dialing in ideal processing parameters smoothens finish.

Do all metal 3D printing methods work with the same powders?

While there is overlap, binder jetting generally uses a broader powder size distribution than powder bed fusion. Some processes are limited to certain alloys based on melting points or reactivity.

How are mixed or bimetallic powders made?

Prealloyed powders ensure uniform properties but for composites, physical powder blending or specialized atomization techniques provide blended elemental powder mixes.

How long does it take to change powder material in a metal printer?

A full purge and changeover between significantly different alloys requires 6-12 hours typically. Quick changes between similar materials can be under an hour.

結論

Optimized metal powders enable additive manufacturing processes to construct complex, robust metal components with superior properties. Matching alloy chemistry and powder characteristics to the printing method and component performance requirements is critical to high quality results. By partnering with experienced powder suppliers, end users leverage expertise in both powder production and 3D printing processes to develop robust AM components faster and more reliably.