3D printing powder is the raw material that enables powder-based additive manufacturing technologies like selective laser sintering (SLS), direct metal laser sintering (DMLS), electron beam melting (EBM), binder jetting and others. There are a growing number of providers offering these specialty powders.

概要 3Dプリンティングパウダー サプライヤー

Companies that manufacture and supply metal and polymer powders suitable for 3D printing include:

- Large integrated metal powder producers

- Specialized 3D printing powder manufacturers

- Chemical companies providing polymers

- Powder distributors and resellers

- 3D printer OEMs with proprietary materials

- Custom toll processors and independent powder makers

They provide key materials like:

- ステンレス

- アルミニウム

- チタン

- コバルトクロム

- 工具鋼

- ニッケル合金

- 貴金属

- Thermoplastic polymers

Many also offer blended alloys, composite mixes, and custom powder varieties tailored to additive requirements across industries.

Types of 3D Printing Powder Manufacturers

There are several major categories of companies involved in this market:

Integrated Metal Powder Producers

These companies manufacture standard powders like metal alloys at scale for a range of industrial uses. They leverage extensive metallurgy expertise to customize select grades specifically for additive.

Dedicated 3D Printing Powder Makers

Focused entirely on developing powders for AM, they work closely with printers and part makers to formulate new alloys and benchmark materials. They rely heavily on toll processors.

Polymer Manufacturers

Major chemical companies optimized to produce large volumes of polymers like nylons and TPU redistribute select material with specifications to suit plastics 3D printing needs.

Powder Distributors

These larger companies focused on various powder markets identify opportunities and source stock materials from major producers to sell specifically into the additive market.

Custom Toll Processors

Equipped with atomization and other primary processing, they can convert specialty metal provided by customers into prototype development lots for evaluation.

Each plays an important part in the complex 3D printing materials supply chain.

Leading Global Suppliers of 3D Printing Powder

Many of the largest metal powder companies now offer 3D printing varieties:

Top Metal Powder Suppliers for Additive Manufacturing

| 会社概要 | 本社 | 主要素材 | 説明 |

|---|---|---|---|

| サンドビック | スウェーデン | Stainless, tool steel, superalloys | Industry leader in high-end metal powder |

| ヘガネス | スウェーデン | Stainless, tool steel, alloys | Major established producer with additive focus |

| リオ・ティント・メタル・パウダーズ | カナダ | Aluminum, titanium, nickel | Large integrated supplier now entering AM |

| ECKA顆粒 | ドイツ | Tool steel, superalloys | Specializes in gas atomized powder |

| プラクセア | アメリカ | Titanium alloys, reactive metals | Supplies aerospace and medical sectors |

| カーペンター・パウダー製品 | アメリカ | Cobalt chrome, stainless, alloys | Custom alloys for 3D printing |

These larger players are steadily increasing their portfolios for additive technologies across materials like aluminum, titanium, tool steel, and nickel alloys.

There are also many smaller powder specialists emerging:

Specialized 3D Metal Printing Powder Producers

| 会社概要 | 所在地 | 材料 | 説明 |

|---|---|---|---|

| エーピーアンドシー | カナダ | チタン、ニッケル超合金 | Focused entirely on demanding AM applications |

| アメリカン・ケメット・コーポレーション | アメリカ | Stainless steel, tool steel, superalloys | Tailors standard alloys to 3D processability |

| LPWテクノロジー | 英国 | Titanium, aluminum, stainless | Designer metal powders for AM |

| パイロジェネシス | カナダ | Titanium, tantalum, rhenium | Produces very high performance grades |

| サンドビック・オスプレイ | 英国 | Stainless steel, maraging steel | Optimizing more alloys for laser powder bed fusion |

These providers work closely with part makers, printer OEMs, and end users to formulate materials with superior 3D printability. They are driving much of the innovation around novel alloys, blends, and composites. More continue to emerge as the market develops.

Major Polymer Material Suppliers for 3D Printing Powder

Most polymer powder for additive manufacturing still derives from large chemical producers:

Leading Suppliers of Polymer Powder

| 会社概要 | 材料 | 説明 |

|---|---|---|

| BASF | PA11, PA12, TPU | Global chemical company optimizing materials for laser sintering |

| DSM | PA11, PA12, PPSU | Specialty chemical firm with polymers for EOS & SLS systems |

| エボニック | PA12, TPU | Diversified chemical company with polymer AM focus |

| Henkel | Thermoplastic Urethane | Adhesives firm with lofted TPU filaments |

| ポリメーカー | Polycarbonate | PLA producer now entering high temperature polymers |

| Victrex | PEEK, PEKK | Leading manufacturer now grades polymers for additive manufacturing |

These companies rely heavily on toll processors and partner with printer OEMs to qualify and distribute their materials into 3D printing channels under various brands. They are collaborating more closely to evolve high performance plastics for AM.

Distributors and Resellers of 3D Printing Powders

In addition to direct ordering from manufacturers, there are several supply chain intermediaries:

Metal Powder Distributors for Additive

| 会社概要 | Key Materials Carried | Geographies Served |

|---|---|---|

| North American Höganäs | Metal powders from Höganäs and others | USA & Canada |

| アトランティック・エクイップメント・エンジニア | Broad range of ferrous and non-ferrous | アメリカ |

| パウダーアロイ株式会社 | Nickel, titanium, aluminum grades | アメリカ |

| American Elements | Wide variety of metals and chemicals | Global |

| LPWテクノロジー | Manufacturer and distributor | Europe, North America |

These larger distributors offer value-added services like inventory storage, logistics, and technical assistance in addition to sourcing and supplying materials. They help connect regional buyers with leading powder makers worldwide.

There are also various national distributors in countries like China, Singapore, India and others that serve more local markets. These include companies like Shanghai ST-powder Equipment. As the AM industry growth accelerates globally, more powder distributors are likely to emerge.

Polymer Material Resellers

Most major chemical firms works through networks of regional distributors and compounds to deliver their sinterable polymer powder. Leading plastic resin and filament suppliers like Polymaker, Clariant, and MakerBot also now carry 3D printing powders. And various ecommerce stores focused on serving the maker community have recently added powdered printing materials to their offerings.

As accessibility expands, more channels for obtaining polymers for powder bed fusion and binder jetting continue to open up.

Range of Materials Available from Powder Suppliers

3D printing providers and powder manufacturers now offer diverse material choices:

Metal Powder Materials for AM

| 素材クラス | 合金の種類 | 特徴 |

|---|---|---|

| ステンレス鋼 | 316L, 304L, 17-4PH, 15-5PH | Corrosion resistance, bio-compatibility |

| 工具鋼 | H13、M2、M4 | Heat and wear resistance |

| アルミニウム合金 | AlSi10Mg, AlSi7Mg | Light weighting, thermal conductivity |

| ニッケル合金 | Inconel 718, 625, Hastelloy | High strength, chemical resistance |

| コバルトクロム | CoCrMo, CoCrWNi | Biocompatibility, wear and heat resistance |

| チタン合金 | Ti6Al4V, TiAl | Aerospace & medical suitability |

New alloys continue to emerge for high temperature, wear, biocompatibility and other needs.

Polymer Powders for Additive

| 素材 | 主要物件 | Printer Compatibility |

|---|---|---|

| Nylon 11, 12 | Strong, versatile | Selective laser sintering |

| TPU plastics | Flexible, elastic | Multi jet fusion, laser powder bed |

| 覗き見 | 耐熱性 | レーザー粉末床溶融 |

| PEKK | Very high temperature performance | New powder bed systems |

| PPSU | Hydrostability, sterilizable | Capable on various printers |

The available materials span the range of metal alloys to high performance polymers, though qualify and optimization for 3D printing continues across providers.

Buying Considerations for 3D Printing Powder

Those purchasing materials for additive manufacturing should consider:

Key Selection Criteria

- Chemistry, composition targets

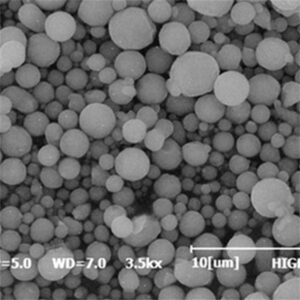

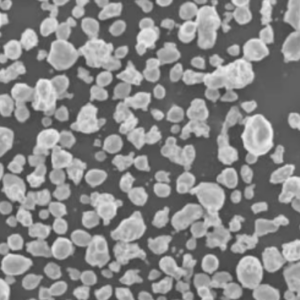

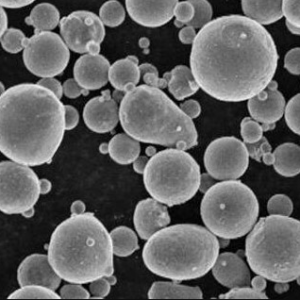

- 粒度分布

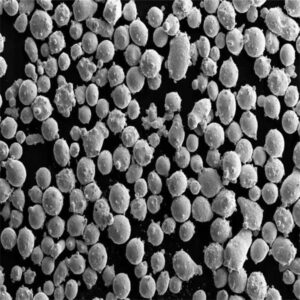

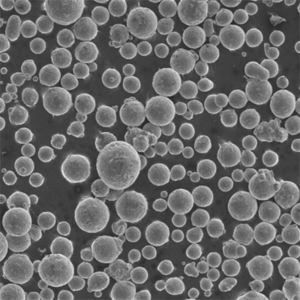

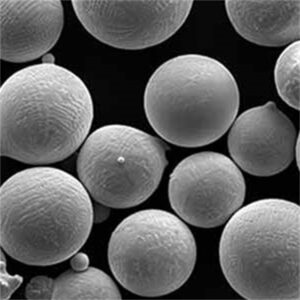

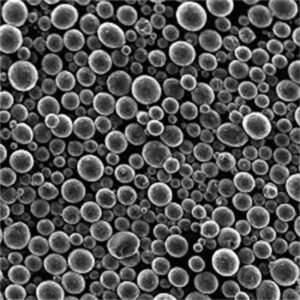

- Morphology: spherical shape preferred

- Apparent density, flow characteristics

- Cost, availability, lead times

- Prior printer validation

- メーカー品質認証

Specifications vary widely across different 3D print technologies. Work directly with your machine OEM or service provider to match the appropriate powder to your application and process requirements.

Comparison of Metal Powder Attributes

| パラメータ | Binder Jet | DMLS | EBM | SLS |

|---|---|---|---|---|

| 粒子径 | 15-50 μm | 15-45 μm | 45-106 μm | 10-45 μm |

| サイズ分布 | Tight | Tight | Wider | Tighter |

| 形 | 球形 | 球形度が高い | より不規則に | 球形 |

| 見かけ密度 | より高い | 中程度 | より低い | 中程度 |

| 表面粗さ | スムーザー | 中程度 | ラフ | 中程度 |

There can be considerable variance in powder characteristics depending on the exact additive technology. Work with your machine supplier or service provider to obtain a powder matched to your printer, parameters and part needs.

Where to Buy 3D Printing Powder

3D printing powder is available through various supply channels:

- Direct from manufacturers: Large entities like Sandvik, AP&C, Höganäs sell direct

- Authorized distributors: Local/regional suppliers of grades from major brands

- Online stores: Various ecommerce sites focused on AM materials

- 3D printer OEMs: Many limit use to their qualified materials

- Print service bureaus: As alternative to owning printer and powder

Industry events like FormNext, RAPID, and Inside 3D Printing feature materials suppliers and may provide sampling opportunities.

When sourcing powder, always:

- Carefully review quality documents, product specifications

- Ask about prior printer validations

- Check availability of particle size distribution graphs

- Review safety data sheets

- Clarify any testing or compliance certifications

Reputable manufacturers provide comprehensive documentation verify their quality claims.

How Much Does 3D Printing Powder Cost?

Cost varies substantially by material:

Typical 3D Printing Powder Pricing

| 素材 | kgあたりの価格 |

|---|---|

| アルミニウム合金 | $25 – $65 |

| ステンレス 316L | $35 – $85 |

| Tool steel H13 | $45 – $120 |

| チタン Ti64 | $170 – $450 |

| コバルトクロム | $110 – $350 |

| インコネル718 | $140 – $600 |

| PA11, PA12 | $55 – $120 |

| 覗き見 | $100 – $600 |

Prices decline at higher purchase volumes. Less common specialty grades are far more expensive. Additional costs accrue for quality checks, special handling, regulated powders. Work with suppliers to optimize delivery, testing protocols and inventory turns for your production profile and risk exposure.

Pros and Cons of Key Powder Manufacturers

Each major powder supplier has relative strengths and limitations:

サンドビック

- 長所だ: Industry leading quality standards, premium materials for demanding applications

- 短所: Limited availability of some alloys, very high pricing for grades like titanium

ヘガネス

- 長所: Broad range spanning stainless, tool steel and aluminum powders; high capacity

- 短所: Perceived lesser sophistication relative to Sandvik; limited U.S presence

エーピーアンドシー

- 長所: Specialized expertise around nickel alloy and titanium grades for aerospace

- 短所: Still overcoming supply continuity issues; limited material selection

リオ・ティント

- 長所: High quality alternative producer entering titanium and aluminum for 3D printing

- 短所: Product range not yet fully commercialized; unproven in AM industry

Consider your application requirements, risk tolerance, and sourcing flexibility when selecting among the growing roster of suppliers serving the additive manufacturing industry.

Qualifying and Testing 3D Printing Powder

Powder producers must verify quality while part makers need to validate materials:

How Manufacturers Test Metal Powder

- Chemistry analysis via optical emission or X-ray fluorescence spectroscopy

- Particle size distribution by laser diffraction

- Shape and morphology via SEM imaging

- Density and flowability per MPIF standard methods

- Mechanical testing on pressed or sintered samples

- Short runs through customer printers for feedstock validation

How End Users Should Qualify Materials

- Review alloy chemistry certificate of analysis

- Confirm particle size distribution meets printer guidelines

- Test flow rate through system powder handling system

- Produce test parts based on standard geometry like tensile bars

- Evaluate achievable density relative to wrought properties

- Assess mechanicals like hardness, tensile strength on printed parts

- Check chemical and microstructural uniformity via microscopy

Both input stock quality and printed output characteristics must meet application requirements over multiple production lots.

Standards Around 3D Printing Powders

While still an emerging area, efforts are underway to introduce more standards:

- ASTM F3049 – Standard guide for characterizing properties of metal powders used for additive manufacturing

- ASTM F3055: Specification for additive manufacturing nickel alloy powders

- ASTM F3301: Classification system for additive manufacturing powders

- ISO/ASTM 52900: General principles around powder bed fusion technology and process characteristics

- DIN SPEC 17071: Designation system for additive manufacturing powders based on process and material categories

These help define test methods, specifications, nomenclature, and best practices. Both global standards bodies and industry trade groups are engaged arounddriving further adoption of guidelines and specificationsapplicable to metal powders for 3D printingand other additive technologies.

Counterfeit Powder Concerns

As the market grows, instances of fraudulent materials have occurred:

- Fake documentation of popular grades like 316L powder

- Misrepresentation of product source and properties

- Unverified powders with dubious quality sold into market

- Risk of poor part performance or even system damage

Protect yourself by:

- Purchasing only from reputable suppliers, approved distributors

- Reviewing documentation like certificates of analysis in detail

- Having new batches independently assayed if any doubt

- Testing powder thoroughly for your process before committing to production runs

Work closely with your critical material suppliers and machine OEM to ensure complete visibility and verification for any new powder lots. As utilization expands, more vigilance is warranted around authentic high quality feedstock.

Future Outlook for 3D Printing Powder Market

The industry is poised for continued strong expansion:

- Broader materials – More metals, composites, and polymers developed

- 改良されたパウダー – Higher purity, finely tailored characteristics

- Supply logistics – Increased stocking distributors provide market access

- Price reductions – As adoption scales, costs decline expanding applications

- Quality standards – Specifications, test methods enable performance guarantees

But further progress requires:

- Continued material advancements meeting application demands

- Printer OEMs validating new grades to expand options

- Smooth supply chainintegration ensuring stock availability

- Measurement techniques to verify acceptable reuse levels

- Defined repeatability metrics to provide user safeguards

With further collaboration between powder manufacturers, printer builders, and end part makers, availability and reliability will continue improving to support a self-sustaining user base.

よくあるご質問

Who are the best 3D printing powder suppliers?

The major global providers like Sandvik, Höganäs, Rio Tinto, Carpenter Powder Products, AP&C and Arcam EBM offer high quality materials for most common AM processes. Which is “best” depends on your specific printer, application, risk tolerance, and location.

Where can I buy small volumes of custom 3D printing powder?

Many major metal powder producers offer prototyping volumes of new alloys. Additional sources for custom powder include toll processors Pyrogenesis, Pyromet, and Specialty Metals Processing. These providers can atomize small batches of new compositions tailored to your requirements.

Should I work directly with a manufacturer or distributor to source powder?

Distributors can provide valuable warehousing, inventory management and shipping services alongside powders sourced from the top producers. This may simplify logistics significantly. But you may access a wider material selection from engaging directly with manufacturers. Define your top requirements around quality, risk, and services to pick the optimal channel.

Are there materials differences across laser and e-beam printers?

Yes, the higher temperature of electron beam melting allows higher alloying levels, larger particles sizes and faster build rates. Materials tailored for DMLM/SLM systems using lasers typically require much tighter chemistry control, smaller particles and lower apparent density. Work closely with your machine vendor to match appropriate powder specifically to your system.