概要 3Dプリントパウダー 供給者

3Dプリント用パウダー, also known as additive manufacturing, uses powders as the raw material to construct components layer by layer. The powders are fused or bound together using heat, laser, or binding agents to create three dimensional objects.

There are several technologies used in 3D printing like Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), Electron Beam Melting (EBM), Binder Jetting, Fused Deposition Modeling (FDM), Stereolithography (SLA) and more. Each process utilizes different types of powders with specific properties and particle size distribution.

3Dプリンティング粉末の種類

| パウダータイプ | 材料 | 特徴 |

|---|---|---|

| プラスチック | Nylon, ABS, TPU, PE, PP | Most common, low cost, less strength |

| 金属 | Aluminum, Stainless steel, Cobalt Chrome, Titanium, Tool steel | High strength, heat/corrosion resistance |

| セラミックス | Glass, Alumina, Zirconia | High temperature uses, brittle |

| Sand & Casting Powders | Silica sand, Zircon sand | For sand molds and cores |

| Magnetic Powders | Iron, Nickel, Cobalt | Applications needing magnetism |

| Biocompatible Powders | Titanium, PEEK, TCP | For medical implants, prosthetics |

Properties of 3D Printing Powders

The key properties of powders used in additive manufacturing include:

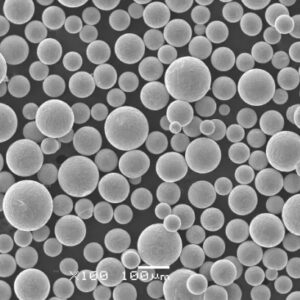

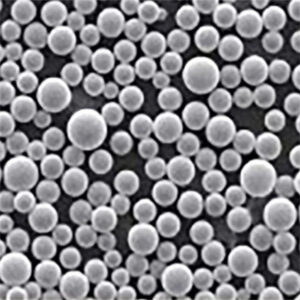

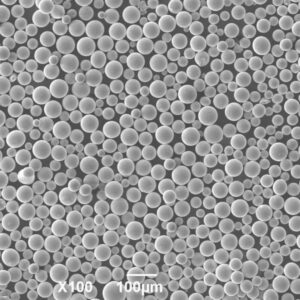

- 粒子径 – Between 10-100 microns, normally distributed

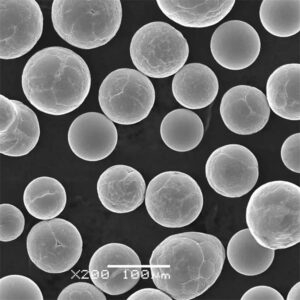

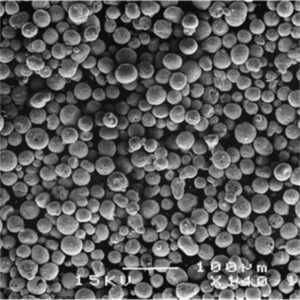

- 形態学 – Spherical shape allows good flowability

- 密度 – Affects product density and microstructure

- 純度 – Determines material compatibility and quality

- 流動性 – Ensures uniform spreading and layering

- 含水率 – Low moisture needed for optimal fusion

- 再利用性 – Some powders can reused to minimize cost

の応用 3Dプリンティング粉末

| 産業 | アプリケーション |

|---|---|

| 航空宇宙 | Turbine blades, jet nozzles, structural frames |

| 自動車 | Prototyping, custom parts like gears |

| メディカル | Dental copings, implants, prosthetics |

| 工具 | Casting patterns, injection molds, jigs & fixtures |

| 建築 | Models, decorative building elements |

| 消費者製品 | Custom designs, rapid prototyping |

3Dプリンティングパウダー仕様

Powder materials used in additive manufacturing must meet strict specifications for particle size distribution, morphology, flowability and purity. Typical size ranges, standards and grades are listed below:

| Material Type | 粒子径(μm) | 規格 | 共通グレード |

|---|---|---|---|

| Polymer powders | 20-150 | ASTM D638 | PA12, PLA, ABS, PC |

| 金属粉末 | 10-45 | ASTM F3049 | Ti-6Al-4V, 17-4PH, 316L |

| Ceramic powders | 10-150 | ASTM F2792 | Zirconia, Alumina, TCP |

| Casting powders | 140-200 | ASTM B213 | Silica sand, Zircon sand |

Global 3d printing powders suppliers

There are both large global suppliers as well as smaller niche powder manufacturers that service the additive manufacturing industry:

Large Powder Producers

| 会社概要 | 材料 |

|---|---|

| サンドビック | Nickel and titanium alloys |

| GKN粉末冶金 | Tool steels, stainless steel |

| ヘガネス | Stainless steels, alloys |

| カーペンター添加剤 | Cobalt chrome, titanium, more |

| BASF | Ultrafine polyamides |

Specialty Powder Producers

| 会社概要 | 材料 |

|---|---|

| LPWテクノロジー | Aluminum, titanium, Ni alloys |

| プラクセア | チタン、ニッケル超合金 |

| アルカムAB | Titanium alloys, CoCr, aluminum |

| 3DXtech | Plastics like ABS, nylon, more |

Cost Analysis of Metal 3D Printing Powders

| 素材 | Powder Cost (USD/kg) |

|---|---|

| ステンレススチール316L | 28-60 |

| アルミニウム AlSi10Mg | 35-95 |

| チタン Ti-6Al-4V | 110-450 |

| インコネル718 | 110-225 |

| コバルト・クローム | 170-400 |

The wide price range depends on purity, whether virgin or recycled powder, particle characteristics, quantity purchased, and supplier terms.

の長所と短所 3Dプリンティング粉末

| メリット | デメリット |

|---|---|

| Complex, lightweight geometries | Comparatively expensive |

| Custom products, rapid prototyping | Limited size based on equipment |

| Reduced wastage versus casting/machining | Powder removal/handling challenges |

| Graded alloys, composites possible | Some post-processing needed |

| Single production step | Porosity in products |

よくあるご質問

Q: What is the most commonly used plastic for 3D printing powders?

A: Polyamide 12 (PA12, nylon 12) is the most popular plastic powder with excellent properties and SLS process compatibility.

Q: What is the difference between virgin and recycled powders?

A: Virgin powders are fresh and unused as compared to recycled powders that originate from prior 3D printed parts. Virgin powder is more expensive but offers higher and more consistent quality.

Q: How are metal powders made for additive manufacturing?

A: Metal powders are made using gas or water atomization to produce fine spherical particles of alloys from melted feedstock under high pressure. The powders may undergo specialized treatments to modify size distribution, morphology, flow or composition.

Q: What precautions should be taken when handling powders?

A: Powder handling procedures must aim to minimize exposure, contain leakage and spills, ensure proper masks/PPE gear, provide adequate ventilation, and implement good housekeeping practices. Some metal powders can combust or explode if handled recklessly.

Q: What powder particle sizes are optimal?

A: Particle sizes ranging from 10 microns to around 100 microns normally offer the best results for spreading thin layers uniformly. Finer nano-scale particles can agglomerate while large particles reduce resolution. Matching particle size to 3D printer requirements is essential.

Q: How are part properties affected by powders?

A: Powder characteristics directly influence density, surface finish, precision, mechanical properties, microstructure and performance of printed components. Graded custom alloys and particle coatings allow tailoring material properties in additive manufacturing.