Aluminum powders refer to aluminum metal in a powder form, composed of fine aluminum particles. They exhibit unique properties that make them suitable for applications in areas ranging from metallurgy and chemicals manufacturing to pyrotechnics and propulsion. Here is an overview of different types, production methods, properties, applications, and suppliers of aluminum powders.

Types of Aluminum Powders

There are two main types of aluminum powders:

| 種類 | 説明 |

|---|---|

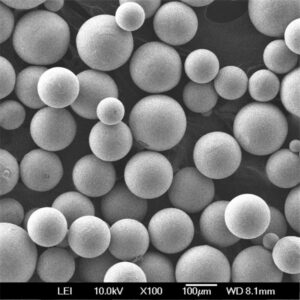

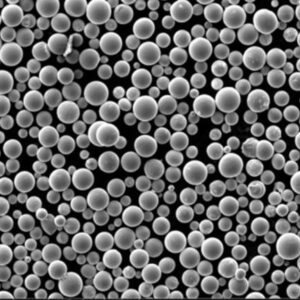

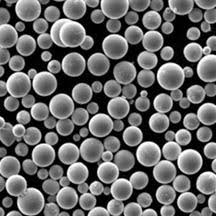

| 球状粉末 | Consists of spherical or rounded particles produced through atomization process |

| Irregular powder | Composed of non-spherical, flakey, irregularly shaped particles produced via milling or grinding |

主な違い Spherical powders have higher bulk density and flowability but cost more. Irregular powders have lower density and flow but are cheaper.

組成と特性

Aluminum powders contain high levels of aluminum metal along with small amounts of other elements:

| エレメント | 組成範囲 |

|---|---|

| アルミニウム(Al) | ≥ 96% |

| ケイ素 (Si) | 0.5-1.5% |

| 鉄(Fe) | 0.4-0.8% |

| 銅(Cu) | 0 – 0.15% |

主な特性

- High chemical reactivity with oxidizing agents

- Low density – around 1.2 g/cm3

- 高い熱伝導性と電気伝導性

- Silver-gray color and appearance

生産方法

There are three main industrial production routes:

- 霧化 – Melted aluminum is broken into droplets that solidify into powder

- ミーリング – Mechanical grinding of aluminum metal into fine particles

- 電解 – Electrochemical reduction of alumina into fine aluminum

Atomization is the most common method, allowing high volumes of spherical powder. Milling gives irregular shapes for niche uses.

Aluminum Powder Grades and Sizes

Aluminum powders are available in various standard grades and sizes:

| グレード | 粒子径範囲 | Average Size |

|---|---|---|

| 粗目 | 44 – 150 μm | 75 μm |

| ミディアム | 15 – 44 μm | 25 μm |

| ファイン | 1 – 15 μm | 5 μm |

| Extra fine | < 1μm | 0.5 μm |

Common industrial grade names include:

- Aluminum bronze powder

- Atomized aluminum powder

- Aluminum flake powder

Applications of Aluminum Powders

Key uses stem from aluminum’s reactive nature, low density, and conductive properties:

| 産業 | Major Applications |

|---|---|

| Metals & Materials | Additive manufacturing powders, brake pads, sand castings |

| 化学物質 | Pyrotechnics, explosives, solid rocket propellants |

| 自動車 | Auto paint pigments, friction modifiers |

| エレクトロニクス | Conductive films, pastes, thermal management |

| 工事 | Thermite welding agents, reactive powder concrete |

Other niches: 3D printing, diamonds tools, inks, and decorative coatings.

Aluminum Powder Suppliers

Leading global suppliers include:

| 会社概要 | 所在地 |

|---|---|

| Toyal America Inc | アメリカ |

| UC RUnited StatesL | 英国 |

| Hokkaido Alpine Co Ltd | 日本 |

| Noranda Aluminum | カナダ |

| Henan Yuanyang Powder Technology | 中国 |

Pricing is approximately $3-6 per kg for typical industrial-grade powder.

Comparison of アルミニウム粉末

| パラメータ | 球形 | 不規則 |

|---|---|---|

| 流動性 | 素晴らしい | 貧しい |

| 梱包密度 | High 0.7-1.2 g/cc | Low <0.5 g/cc |

| コスト | より高い | より低い |

| 反応性 | 中程度 | 高い |

| Automation suitability | Ideal | Challenging |

要点

- Spherical, atomized powders have better handling but irregular types maximize surface area and reactivity at a lower cost.

- Finer grades below 10 microns show stronger explosive potentials needing cautious handling.

- Aluminum powders drive innovation in materials technology through unique chemistry and metastability.

よくあるご質問

What are the hazards of aluminum powders?

As reactive metals, aluminum powders can pose explosion hazards when handled incorrectly, especially at particle sizes under 5 microns. They require inert storage conditions and safety measures.

What is aluminum powder coating?

Aluminum powder coating refers to a specialized protective finish containing aluminum pigments. It is applied through electrostatic spraying and baked to form a decorative and corrosion-resistant coating.

What is the difference between aluminum flake and aluminum paste?

Aluminum flake contains leafing aluminum pigments with high aspect ratios used in coatings. Aluminum paste has the flake dispersed in a liquid carrier for easier application as a thick film paint or polish.

What is the shelf life of aluminum powders?

Properly stored aluminum powders have an approximate shelf life of up to 3 years before noticeable oxidation effects. Finer grades under 10 microns deteriorate faster and require moisture-free inert storage. Reactive specialty grades like pyro powders are the most sensitive.