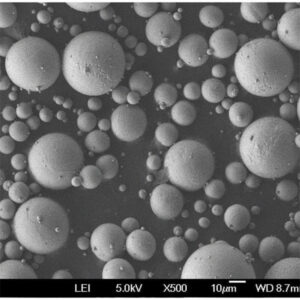

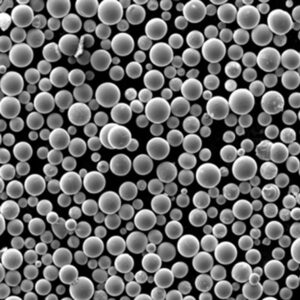

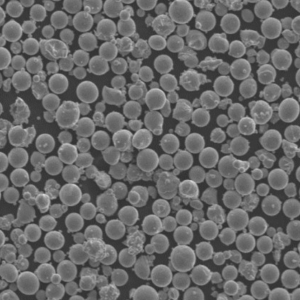

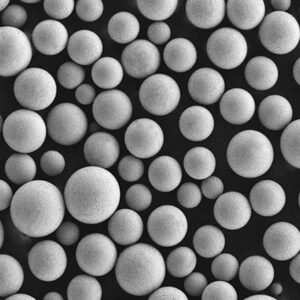

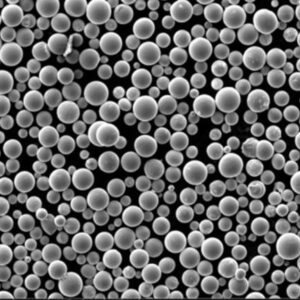

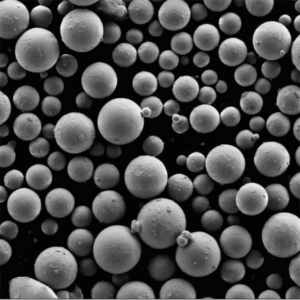

Atomized metal powders refer to metallic materials like aluminum, titanium, nickel, iron or alloys that have been reduced to fine spherical powder form through an atomization process. They exhibit high purity, consistent particle sizes, and powder morphology ideal for industrial applications like metal injection molding (MIM) and additive manufacturing.

This guide covers different types of atomized metal powders, production methods, key properties and characteristics, technical specifications, pricing estimates, supplier details as well as pros, cons and common FAQs when working with precisely engineered, atomized metallic powders across 3D printing, injection molding and other fabrication processes.

種類 アトマイズ金属粉

Common base metals and alloys available as atomized spherical powders include:

| 素材 | 合金 | 特徴 |

|---|---|---|

| アルミニウム | 6061, 7075, 2024, 7050, | Lightweight, moderate strength |

| チタン | Ti-6Al-4V, Ti 6Al-7Nb | Optimized strength-to-weight ratio |

| ニッケル | Inconel 718, Invar 36, Kovar | Heat/corrosion resistant options |

| ステンレス | 316L, 430F, 17-4PH | Rust resistant, high hardness variants |

| 銅 | C11000, Brass, Bronze | 高い熱伝導性と電気伝導性 |

Properties can be tailored across corrosion resistance, hardness, strength, ductility, operating temperatures and other attributes by alloying mixtures.

生産方法

Techniques for producing precision metal microspheres in powder form:

| 方法 | 説明 | 典型的な出力 |

|---|---|---|

| ガス噴霧 | High velocity inert gas jets disintegrate molten metal stream into fine droplets | Excellent powder sphericity and flowability |

| 回転電極 | Centrifugal forces disperse molten metal poured on spinning disk | Medium powder sizes, lower cost |

| プラズマ霧化 | Very high temp plasma rapidly solidifies molten stream in controlled gas flow | Sub-10 micron nano powder capability |

| 超音波霧化 | Sound waves at 20+ kHz oscillate and detach microscopic droplets | For specialized small batch needs |

Gas and plasma produce the highest purity with consistent particle distributions for demanding applications like aerospace alloys. Rotating electrode method offers economical medium batches.

Properties of Atomized Metal Powders

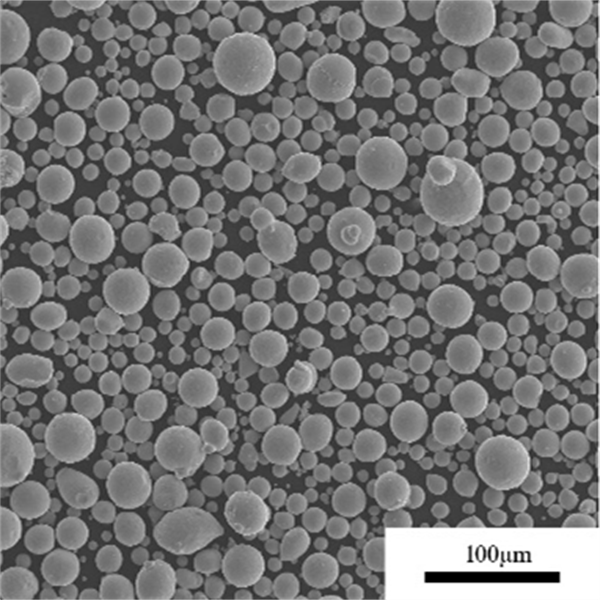

Benefits of these precisely shaped and sized metallic microspheres:

| プロパティ | 特徴 | メリット |

|---|---|---|

| Controlled particle size | Majority of powder in narrow 5-45 micron range | Optimized flow and packing for sintering consistency |

| High sphericity | Powder balls exhibit very round shape with smooth surface | Improves final density and surface finish quality |

| Consistent chemistry | Precisely formulated alloys during production | Reliable material performance batch to batch |

| 高純度 | Inert processing without contamination | Necessary for biocompatible implants and electronics |

| Modified surfaces | Coatings or lubricants can be added | Improves powder flow and reduces caking risks |

These powders represent ideal raw materials shaped by cutting edge manufacturing means to enable emerging fabrication techniques reshaping industrial production across sectors through enhanced precision.

の応用 アトマイズ金属粉

Major uses of precision spherical metallic powders:

| 産業 | アプリケーション | メリット |

|---|---|---|

| 積層造形 | 3D printed aerospace, automotive, medical parts | Excellent flowability through fine powder spreading and recoating mechanisms |

| 金属射出成形 | Small complex part series for drones, robots, turbines | High purity and consistent chemistry yields reliable material performance |

| Electronic packaging | Circuits, sensors, connectors | Sintered porous structures aid miniaturization while allowing functional material infiltrations |

| 溶射 | Protective anti-corrosive coatings for bridges, pipelines | Dense coatings with bonding optimized particle morphology |

| 粉末冶金 | Self-lubricating bearings, filters, magnets | Net and near net shape fabrication simplifies manufacturing steps |

The precision particle engineering behind atomized powders combined with specialized process expertise unlocks game changing production innovations across these key sectors.

仕様

| スタンダード | Definitions | Common Values |

|---|---|---|

| ASTM B214 | Sieve Analysis for particle upper limit percentages | -325 mesh = less than 45 microns |

| ASTM B822 | Apparent density g/cm3 | Around 35-50% as loose powder |

| ASTM B964 | Flow rate second/50g | 15 – 25 seconds range |

| ASTM F3049 | Chemistry inclusions content max ppm limits | Fe 300 ppm, O 1500 ppm, N 100 ppm |

International specifications help set consistent baselines defining acceptable material quality and purity thresholds for proper powder performance during loading and sintering stages across various fabrication techniques.

サプライヤーと価格

| サプライヤー | 材料 | 価格帯 |

|---|---|---|

| サンドビック・オスプレイ | Titanium, Nickel, Cobalt alloys | $50 – $500 per kg |

| カーペンター・パウダー | Stainless steels, Tool steels | $20 – $250 per kg |

| Praxair Surface Tech | Ni superalloys, Waspaloy, Hastelloys | $100 – $1000 per kg |

| Atmix Corp | Custom aluminum alloys | $30 – $200 per kg |

Costs range widely from $20 per kg for common stainless steel alloys to over $1000 per kg for specialized heat resistant superalloys leveraging custom vacuum induction melting and tightly controlled gas atomization parameters tailored to demanding applications like turbine engine components.

Remember – buy the specification not just the powder material alone when comparing options.

長所と短所

| 長所 | 短所 |

|---|---|

| Excellent morphological control through cutting edge manufacturing methods | Potentially high material price points, especially for highly customized alloys |

| Unlocks disruptive part fabrication techniques like binder jetting and DED additive printing | Limited large volume capacity compared to conventional metal production like casting and forging |

| Simplifies downstream operations through high purity and flowability | Requires handling expertise and precautions to prevent oxidation risks |

| Expands range of alloys tailored to demanding applications | Supply chain volatility as niche producers balance small batches |

| Enables complex geometries impossible through subtractive techniques | Post processing often needed to achieve final material properties |

The precise control over powder shape, size, distribution and chemistry conveys tremendous advantages but specialized handling and processing considerations must be addressed.

制限と考慮事項

Working with atomized powders carries unique considerations:

- Chemically active metals like titanium risk burning if oxygen content exceeds 25 ppm

- Must follow safety precautions given flammability of very fine metallic powders

- Surface treatments may degrade during high temperature sintering or welding

- Require high precision tooling for filling containers halves and cylinders reliably

- Flowability can regress over time through agglomeration during storage and transport

- Controlling moisture ingress below 300 ppm necessary for stability

- Note loose powder packing density only 30-55% of final consolidated densities

Engineers should select vendors capable of sustainably delivering customized alloys meeting evolving application needs instead of merely comparing on price per kg alone.

よくある質問

| 質問 | 答え |

|---|---|

| What is the main advantage over water atomized metal powder? | More precise control over particle shape and size distribution consistency |

| 一般的なかさ密度は? | Around 2-4 g/cc is common depending on alloy and particle sizes |

| What is flow rate measured in? | Sec/50g gives indication of powder morphological flow through equipment |

| What particle size testing is used? | Laser diffraction particle size analyzers in liquid suspensions |

| How is chemistry tested? | ICP-OES or GDMS methods used to validate elemental compositions |

| パウダーの賞味期限は無制限ですか? | Generally over 5 years if kept sealed from oxygen/moisture, retest after 2-3 years |

| What care is needed when handling? | Inert environment glove boxes for Titanium, appropriate PPE for other reactive metals |

| What are common applications? | MIM, Binder jetting and DED AM are leading uses currently |

Proper handling and testing processes combined with matched customer application requirements will drive continuing adoption of atomization technology across fabricated metal parts production.

結論

The advanced manufacturing prowess required to mass produce precisely engineered metallic microspheres unlocks tremendous fabrication possibilities across industrial sectors. By leveraging processes like gas atomization to control critical powder characteristics like particle size distribution, shape, purity and chemistry, engineers can take full advantage of emerging techniques like additive manufacturing to simplify production flows. And specialized alloy variants expand the design envelope across challenging temperature, pressure and caustic operating environments. Combine that with lower waste compared to machining processes and simplified logistics through enhanced metal powders shelf life, and innovative businesses are just starting to tap the potential through increased R&D investments tailored to application needs. But proper handling and safety considerations around reactive elemental powders remains mandatory. As additive manufacturing continues its growth trajectory into full scale certified production across aerospace, medical implantation and automotive innovators, expect precise atomization technology to play a crucial role supplying raw materials differentiating leading manufacturers through access to customized, qualified alloys.