Inconel 600 is a standard engineering material for high temperature applications up to 1100°C. This guide covers Inconel 600 powder compositions, properties, manufacturing methods, applications, specifications, pricing, comparisons, and frequently asked questions when considering this nickel-chromium-iron alloy.

Typical Composition of Inconel 600 Powder

| エレメント | 重量 % |

|---|---|

| ニッケル | 72% min |

| クロム | 14-17% |

| 鉄 | 6-10% |

| カーボン | 最大0.15% |

| マンガン | 最大1% |

| 硫黄 | 0.015%最大 |

| シリコン | 最大0.5% |

| 銅 | 最大0.5% |

The nickel-chromium balances high temperature strength with fabricability. Low carbon content minimizes harmful carbide precipitation during exposures above 550°C.

主な特性と特徴

- Excellent high temperature strength up to 1150°C

- Resists chloride stress corrosion cracking

- More ductile than higher alloyed Inconels

- 100% weldable for similar or dissimilar material joints

- Hot workable using standard fabrication techniques

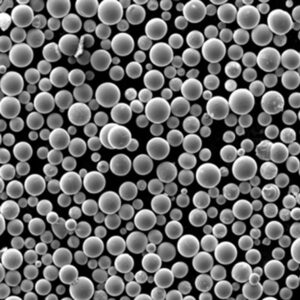

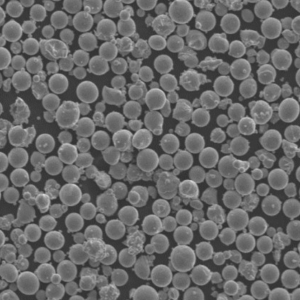

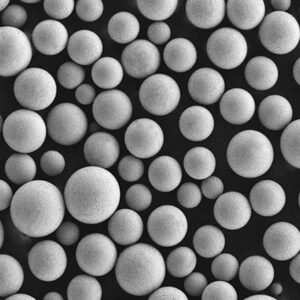

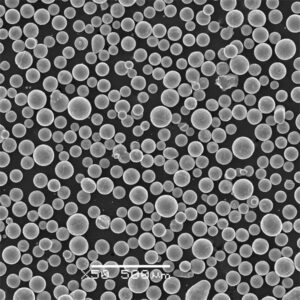

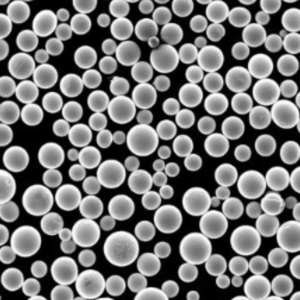

- Available in argon gas atomized spherical powder

の応用 Inconel 600 Powder

| 産業 | Common Components |

|---|---|

| 航空宇宙 | Exhaust components, fasteners |

| ケミカル | Heat treating fixtures, reaction vessels |

| 石油・ガス | Wellhead control lines, downhole tools |

| Pollution Control | Coal gasification, exhaust recuperators |

| 食品加工 | High pressure steam lines |

Good blend of fabricability and heat resistance suits Inconel 600 for demanding thermal environments needing occasional alloy welding, brazing or soldering steps during manufacturing or service.

Inconel 600 Powder 仕様

| スタンダード | Grades Coverd |

|---|---|

| ASTM B163 | Seamless nickel and nickel alloy pipes |

| ASTM B564 | Welded nickel and nickel alloy conduits |

| ISO 14577 | Metallic materials for laser powder bed fusion |

No specifications explicitly for powder; application determines acceptance criteria. Standards for wrought product used as baseline.

Global Suppliers and Price Range

| 会社概要 | リードタイム | 価格/kg |

|---|---|---|

| サンドビック・オスプレイ | 10-14 weeks | $50-$150 |

| TLSテクニーク | 16 weeks | $60-$180 |

| アトランティック・エクイップメント | 12 weeks | $45-$130 |

Prices for 100+ kg quantity. Significant cost reduction above 500 kg volumes possible through negotiations.

比較分析

| 属性 | インコネル600 | インコネル625 | Hastelloy B-2 |

|---|---|---|---|

| Max temperature | 1150℃ | 1050°C | 1260°C |

| 耐食性 | 中程度 | 非常に良い | 素晴らしい |

| コスト | 低い | 高い | 非常に高い |

| Formability | 素晴らしい | 中程度 | 貧しい |

Among Ni alloys, Inconel 600 strikes best balance of temperature rating, fabricability and alloy cost. Prefer others if extreme corrosion or heat needed.

よくあるご質問

Why is Inconel 600 preferred for high temperature fasteners?

Easy forming and joining characteristics facilitate nut and bolt manufacturing unlike highly alloyed grades needing specialty processing. Good creep strength above 550°C suits turbocharger applications.

What particle size range works best for laser powder bed fusion?

Around 25 to 45 microns optimal for balancing surface finish, resolution, and build speed. Too coarse powders hurt density and accuracy. Verify size distribution for adequate flowability.

What process parameters matter most when printing Inconel 600 parts?

Energy density, preheat control, powder spread parameters that ensure dense melting without excess oxidation or residual stresses leading to cracking during build and heat treatment steps.

What heat treatments apply for additively manufactured Inconel 600?

Stress relief aging similar to wrought processing helps attain consistent properties – 1050-1120°F for 1-3 hours typically specified. Precipitation treatments less common.

How is used Inconel 600 powder recycled?

retrieval systems filter, sieve, blend about 20-30% reused powder with fresh material continuously. Monitor oxygen levels and re-use fraction limits to avoid contamination issues.

結論

To summarize, Inconel 600 powder provides an optimal combination of formability, weldability and heat resistance essential for component fabrication across demanding industries via additive manufacturing or other powder metallurgy techniques.