Inconel 625 is a nickel-based superalloy widely used across aerospace, chemical processing, and energy industries owing to its high strength, corrosion resistance, and temperature capabilities. This guide covers インコネル625粉 properties, manufacturing methods, industry applications, post-processing procedures, and suppliers.

Introduction to Inconel 625 Alloy Powder

Inconel 625 is a high performance alloy composed primarily of nickel, chromium, and molybdenum. Key characteristics include:

表1: Inconel 625 powder overview

| プロパティ | 詳細 |

|---|---|

| ニッケル含有量 | 58-63% |

| 密度 | 8.44 g/cm3 |

| 融点 | 1,260-1,340°C |

| 引張強さ | 1,240 MPa |

| 降伏強度 | 550 MPa |

| 伸び | 30% |

| 耐食性 | Excellent in extreme environments |

| 作業性 | Readily welded and fabricated |

These properties support use across chemical processing, aerospace components, and oil/gas hardware. Additive manufacturing expands possibilities for custom, complex Inconel 625 parts.

化学組成

The Inconel 625 alloy composition consists of:

表2: Inconel 625 standard chemistry

| エレメント | 重量 % | 役割 |

|---|---|---|

| ニッケル(Ni) | 58.0 – 63.0% | Matrix element |

| クロム(Cr) | 20.0 – 23.0% | 耐酸化性 |

| モリブデン (Mo) | 8.0 – 10.0% | 強化 |

| ニオブ | 3.15 – 4.15% | Precipitate hardening |

| 鉄(Fe) | ≤ 5% | Tramp element |

| カーボン(C) | ≤ 0.10% | Impurity limit |

| マンガン (Mn) | ≤ 0.5% | Residual |

| ケイ素 (Si) | ≤ 0.5% | 脱酸素剤 |

| リン (P) | ≤ 0.015% | Impurity limit |

| 硫黄(S) | ≤ 0.015% | Impurity limit |

| アルミニウム(Al) | ≤ 0.4% | Impurity limit |

Careful optimization of nickel, chromium, molybdenum, and niobium is key for achieving desired mechanical properties.

Key Properties of Inconel 625 Powder

表3: Inconel 625 powder properties

| プロパティ | 価値 |

|---|---|

| 密度 | 8.44 g/cm3 |

| 融点 | 1,260-1,340°C |

| 熱伝導率 | 9.8 W/m-K |

| 電気抵抗率 | 134 μΩ-cm |

| 弾性係数 | 207 GPa |

| ポアソン比 | 0.29 |

| 引張強さ | 1,240 MPa |

| 降伏強度 | 550 MPa |

| 伸び | 30% |

| 硬度 | ~36 HRC |

These attributes enable using Inconel 625 in load-bearing applications up to 700°C where resistance to thermal fatigue, oxidation, and creep are critical.

Production Method for インコネル625パウダー

表4: Inconel 625 powder production methods

| 方法 | 説明 | 特徴 |

|---|---|---|

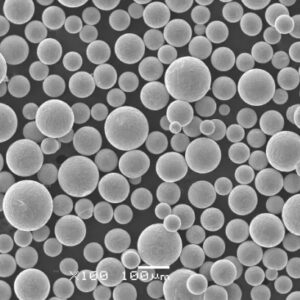

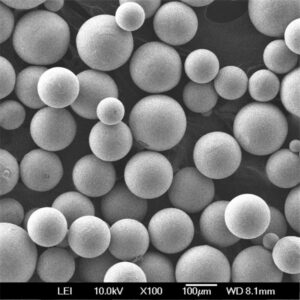

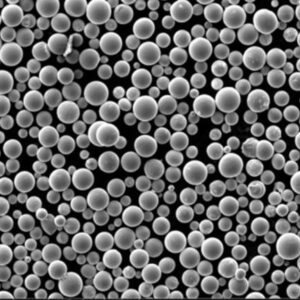

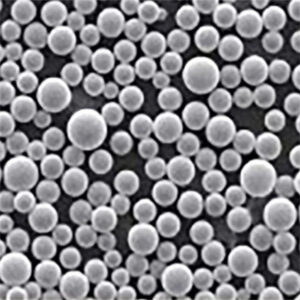

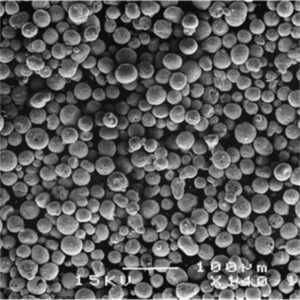

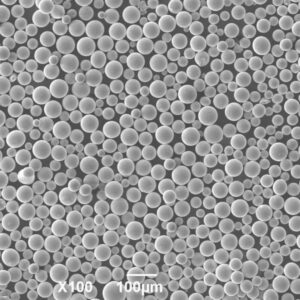

| ガス噴霧 | High pressure gas nozzle disintegrates molten metal stream | Spherical powder ideal for AM |

| プラズマ霧化 | Electrodes melted by plasma arcs/torches into droplets | Controlled powder size distribution |

| 回転電極 | Centrifugal disintegration of spinning molten metal by electric arcs | Narrowest particle distribution |

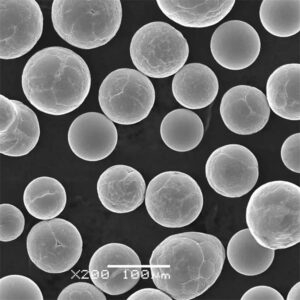

Advanced gas atomization processes allow tuning powder shape, surface chemistry, defects, and particle size distribution suitable for additive manufacturing to minimize porosity.

インコネル625パウダーの用途

The combination of strength, fracture toughness, weldability and corrosion resistance make Inconel 625 suitable for:

表5: Inconel 625 powder applications

| 産業 | コンポーネント |

|---|---|

| 航空宇宙 | Turbine blades, combustion cans, rocket nozzles |

| 石油・ガス | Wellhead valves, downhole tools, drilling pipe |

| 化学処理 | Reactor vessels, heat exchanger tubing |

| 発電 | Gas turbine hot section parts, fuel nozzles |

| 自動車 | Turbocharger turbines, exhaust components |

| マリン | Desalination systems, propellers, fittings |

In particular, additive enables cost-effective short run production of custom Inconel 625 components.

Inconel 625 Powder Specifications

表6: Inconel 625 powder specifications

| パラメータ | 価値 |

|---|---|

| 純度 | >99.9% |

| 粒子径 | 15-45ミクロン |

| 形態学 | 球形度が高い |

| フェーズ | Solid solution γ-Ni + γ”-Ni3Nb |

| 酸素含有量 | <300ppm未満 |

| 見かけ密度 | Typically >4 g/cm3 |

| 流量 | Hall flowmeter >23 sec/50g |

Tight control of powder quality and optimization for AM achieves dense printing and superior as-fabricated material performance.

グローバルサプライヤー

Leading Inconel 625 powder suppliers for AM include:

表7: Inconel 625 powder manufacturers

| 会社概要 | 所在地 |

|---|---|

| サンドビック | ドイツ |

| プラクセア | 米国 |

| カーペンター添加剤 | 米国 |

| エーピーアンドシー | カナダ |

| エラスティール | スウェーデン |

| テクナ | カナダ |

These premium specialists offer atomized Inconel 625 powder with controlled particle size, shape, chemistry, and defect population tailored for additive manufacturing applications.

インコネル625パウダー価格

表8: Inconel 625 powder price dynamics

| パラメータ | 詳細 |

|---|---|

| 数量 | Price per kg drops above ~50 kg |

| 品質 | Higher grades for AM cost 2-4x more than conventional powder |

| 流通 | Tighter particle distributions more expensive |

| Shape factors | High sphericity/smoothness increase price |

In general, Inconel 625 powder ranges from $50/kg to $150/kg for specialized varieties optimized for laser powder bed fusion or directed energy deposition printing.

Pros vs Cons of インコネル625パウダー

表9: Inconel 625 powder advantages and challenges

| 長所 | 短所 |

|---|---|

| Withstands extreme environments | Lower elongation/toughness than nickel alloys |

| Five times more fracture resistant than steel | ひずみひび割れしやすい |

| Half the density of steel | Expensive compared to stainless steel |

| Resists hot corrosion and pitting | Very high processing temperatures |

| カスタム合金の開発が可能 | Tendency for porosity in AM parts |

| Complex geometries from AM consolidation | Requires extensive post-processing |

| Reduces lead times and cost for short runs | Limited large volume industrial suppliers |

With sound design and printing parameters, Inconel 625 enables lighter, stronger and more integrated components across demanding applications.

よくある質問

Q: What particle size distribution is optimal for printing Inconel 625?

A: An Inconel 625 powder with particle sizes ranging from 15-45 microns allows high packing density and limits porosity during printing.

Q: What causes cracking in additively manufactured Inconel 625 parts?

A: Large residual stresses from the extreme thermal gradients during printing lead to cracking. Process optimizations like pre/post heating and providing structural supports are essential.

Q: What finish can be expected on as-printed Inconel 625 components?

A: Raw surface roughness typically ranges from 5-15 microns. Additional machining, grinding, electropolishing and other finishing produces smoother surfaces.

Q: What post-processing method is recommended for additive manufactured Inconel 625 parts?

A: Heat treatment, hot isostatic pressing, and surface conditioning are all recommended to relieve stresses, increase density, and improve surface finish.