金属粉末アトマイズ法 is a critical technology for producing fine metallic powders with specialized characteristics. This guide covers the fundamentals, methods, applications and commercial landscape of metal powder atomization.

What is Metal Powder Atomization?

Metal powder atomization refers to industrial processes that turn molten metal alloys into fine liquid droplets, rapidly solidifying them into powder particles.

It involves:

- Melting metals into a liquid state

- Generating a molten metal stream

- Breaking up the metal into discrete droplets

- Solidifying the droplets into powder

- Collecting and sieving the powder

Atomization is used to produce metal powders with unique compositions, sizes, shapes and microstructures suitable for advanced applications.

Key Atomization Benefits

- Custom alloy compositions

- Controlled particle sizes

- Spherical powder shapes

- Defect-free powder metallurgy

- Novel microstructures

- Custom powder properties

Common materials made through atomization include various alloy systems:

- ステンレス鋼

- 工具鋼

- コバルト合金

- ニッケル合金

- チタン合金

- Tungsten alloys

- 貴金属

Metal Powder Atomization Methods

There are 5 main commercial atomization techniques:

ガス噴霧

- Uses pressurized inert gas jets

- Common gases: Nitrogen, Argon, Helium

- Produces spherical, smooth powders

水の霧化

- Uses high pressure water jets

- Lower cooling rates than gas

- Irregular powder shapes

遠心霧化

- Molten metal poured on spinning disc

- Economical powder production

- Medium cooling rates

超音波霧化

- Uses ultrasonic vibrations

- Specialized lab-scale method

- Nanoparticle production

Electrode Induction Melting

- Electrode vaporization in inert gas

- Limited niche applications

- Lower productivity

Atomization Method Comparison

| 方法 | 粒子形状 | サイズ範囲 | 生産性 | コスト |

|---|---|---|---|---|

| ガス噴霧 | 球形 | 10-150 μm | 高い | 高い |

| 水の霧化 | 不規則 | 20-400 μm | 非常に高い | 低い |

| 遠心霧化 | Semi-spherical | 20-250 μm | ミディアム | ミディアム |

| 超音波霧化 | 球形 | 1-100 nm | 非常に低い | 高い |

| Electrode Induction Melting | Mixed | 10-100 μm | 低い | ミディアム |

Metal Powder Atomization プロセス

Commercial metal powder atomization involves a series of tightly controlled steps under inert atmosphere:

1. Raw Material Selection

- Pure metals or master alloys

2. Melting

- Vacuum induction melting up to 2000°C

- Precise alloy chemistry inputs

3. Atomization

- Pouring molten metal into atomizing zone

- Breaking up metal stream into droplets

- Quenching and solidifying droplets

4. Powder Collection

- Settling chamber to collect powder

- サイクロンセパレーター

5. Sieving

- Classifying powder into size fractions

- Further annealing if needed

6. Quality Control

- Sampling and testing per standards

- Packaging and shipment

The production environment must have no oxygen or moisture contamination. Operational parameters like temperature profiles, gas pressures and flow dynamics are closely monitored.

Metal Powder Atomization Applications

Some major applications taking advantage of atomized metal powder include:

アディティブ・マニュファクチャリング

- 選択的レーザー溶融

- バインダー噴射

- 電子ビーム溶解

金属射出成形

溶射コーティング

熱間静水圧プレス

Brazing Materials

触媒

粉末冶金

- プレス・焼結金型

- 高性能部品

- Porous structures

- Soft magnetic composites

Atomized powder enables emerging technologies like additive manufacturing across industries:

| 産業 | アプリケーション | メリット |

|---|---|---|

| 航空宇宙 | Turbine blades, impellers, airframe components | 高い強度対重量比 |

| 自動車 | Gears, connecting rods, chassis parts | Increased efficiency |

| メディカル | Joint replacements, implants, precision tools | 生体適合性 |

| エレクトロニクス | Shielding, contacts, sensors | Enhanced performance |

| 石油・ガス | ダウンホールツール、バルブ | Wear and corrosion resistance |

Metal Powder Atomization Materials

Many alloy systems and material types are processed through atomization:

ステンレス鋼

- Austenitic grades like 304, 316, 317

- Ferritic and martensitic grades

- Custom compositions available

工具鋼

- H13, P20, D2, M2 grades

- 高い耐摩耗性

- High hardness after heat treatment

コバルト合金

- Biomedical CoCrMo alloys

- Wear resistant StelliteTM alloys

ニッケル合金

- Corrosion resistant alloys like Inconel 625

- Heat resistant superalloys

チタン合金

- Ti6Al4V grade 5 titanium

- Commercially pure titanium

耐火金属

- Niobium, molybdenum, tungsten

- Very high melting points

Metal Powder Atomization: Specifications

Critical specifications for atomized metal powders include:

粒度分布

- Typically 10 to 150 microns

- Application method dictates ideal size

- Sieving classifies desired fractions

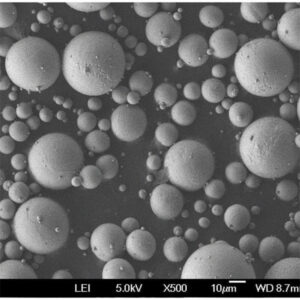

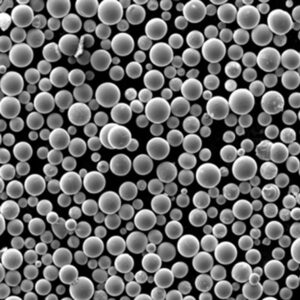

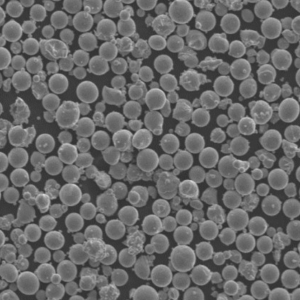

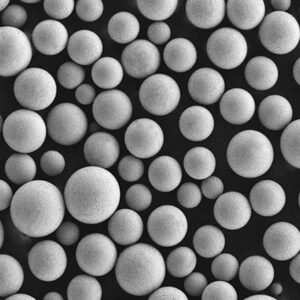

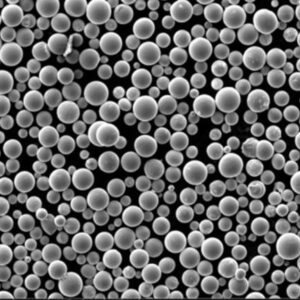

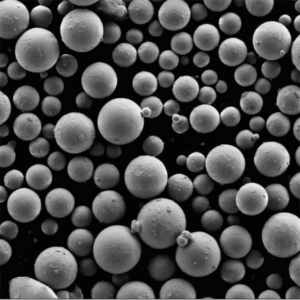

粒子形状

- Spherical, smooth morphologies

- Impact compaction, flowability

化学

- Precisely blended compositions

- Custom alloys designed for properties

密度

- Up to 98% theoretical density

- Density optimization modeling

表面積

- Relatively high surface area

- Impacts reactivity, solubility

微細構造

- Controlled grain sizes and phases

- Rapid solidification dynamics

| パラメータ | 意義 | Measurement Technique |

|---|---|---|

| 粒度分布 | Controls downstream processability | レーザー回折式粒度分布測定装置 |

| 粒子形状 | Impacts density and flow behavior | 走査型電子顕微鏡 |

| 化学 | Achieves target material performance | Optical emission spectrometry, ICP mass spectroscopy |

| 密度 | Related to achievable properties | Gas pycnometry, apparent density tester |

| 表面積 | Affects reactivity and solubility | Gas absorption surface area analyzer |

| 微細構造 | Determines mechanical properties | X-ray diffraction, metallography |

Metal Powder Atomization Cost Analysis

Atomized metal powder is more expensive than conventional raw materials due to specialized processing:

- Small batch production

- Complex quality control

- Manual handling steps

- Equipment maintenance

- Consumables and energy

- R&D expense recovery

Cost Drivers:

- Feedstock metal costs

- Quality conformance

- Order size

- 粒子径

- エキゾチック合金

Economics:

- Raw materials: 30% of total cost

- Processing: 70% of total cost

価格帯

| 素材 | kgあたりの価格 |

|---|---|

| ステンレス鋼 | $20-$250 |

| 工具鋼 | $25-$150 |

| チタン合金 | $70-$1000 |

| コバルト合金 | $100-$500 |

| ニッケル合金 | $100-$2000 |

| Tungsten Alloys | $800-$5000 |

Business viability relies on maximizing production capacity utilization and end-to-end yield.

Metal Powder Atomization: Pros vs Cons

Benefits of Metal Powder Atomization

- Excellent flow characteristics

- Narrow particle size distribution

- Customizable alloy compositions

- Spherical powder shape possible

- 制御された微細構造

- Enables emerging technologies

Challenges of Metal Powder Atomization

- High production cost

- Limited batch sizes

- Stringent safety precautions

- Complex quality conformance

- Qualified operator experience vital

- Costly trial-and-error development

- Handling fine reactive powders

Advancements continue expanding the horizons for specialty materials made via atomization.

よくあるご質問

Q: How are metal powders atomized?

A: Metal powders are atomized by breaking up a molten metal stream into fine droplets using gas jets, water jets or centrifugal forces, rapidly solidifying them into powder.

Q: What is water atomization?

A: In water atomization, a thin stream of molten metal alloy is struck by high-pressure water jets which break it up into small droplets. The droplets solidify into irregularly shaped powder particles as they fall through the water.

Q: どんな金属をアトマイズして粉末にできますか?

A: Many engineering metals like tool steels, stainless steels, nickel alloys, titanium alloys, tungsten alloys and precious metals can be atomized into fine spherical powders or irregular powders using appropriate techniques.

Q: What particle sizes can metal powder atomization achieve?

A: Conventional metal powder atomization can produce powders from around 10 microns to over 150 microns. Specialized nozzles and processing conditions allow particle sizes below 5 microns.

Q: How much does metal powder atomization cost?

A: Due to small volumes and specialized equipment, atomized metal powder costs between 5x to 10x more than standard raw metal stock per unit weight, with pricing ranging from $50 per kg to over $2000 per kg depending on composition and quality.

Q: Can you atomize multiple metals simultaneously into an alloy?

A: Yes, atomization allows melting and alloying various metals into customized compositions which solidify into an alloy powder with the desired elemental ratios and advanced metallurgical properties.

Q: What hazards are associated with metal powder atomization?

A: Fine metal powders may spontaneously combust, explode or be toxic if inhaled. Strict safety protocols for inert gas purging, explosion proof electrical equipment, pressurized nozzles, emergency ventilation and operator PPE are enforced.

Q: What machines are used in metal powder atomization?

A: The main metal powder atomization equipment includes vacuum induction furnaces, tundish pouring systems, gas and water jet nozzles, atomizing towers, cyclone separators, screening machines, powder drying ovens and sieving station.

結論

Metal powder atomization is an intricate, multi-faceted manufacturing technique essential for new material development crossing industry boundaries. Persistent metallurgical challenges continue driving process refinements through extensive tribology research and plant trials. With broader collaboration across the metal powder value chain harnessing latest automation technologies, atomization promises to elevate manufacturing—not eliminate it.