概要

金属粉末 は、積層造形、金属射出成形、粉末冶金プレス・焼結などの製造技術の原料として使用される微細金属粒子である。化学組成、粒度分布、形態、微細構造を精密に制御して高度な特殊金属粉末を製造することは、完成部品の特性にとって極めて重要である。

さまざまな合金系から金属粉末を大量生産するためには、以下のようなさまざまな方法がある:

- ガス噴霧

- 水の霧化

- プラズマ霧化

- 電極誘導溶解ガス噴霧

- 回転電極プロセス

- カルボニルプロセス

- 電解プロセス

- 金属還元プロセス

それぞれの工程は、特定の用途に適した異なる特性を持つパウダーを生み出す。

金属粉末の製造方法

| 方法 | 使用金属 | 主な特徴 | 主な用途 |

|---|---|---|---|

| ガス噴霧 | チタン, アルミニウム, ステンレス鋼, 工具鋼, 超合金 | 球状パウダー、中程度の生産速度 | 金属射出成形、熱間静水圧プレス |

| 水の霧化 | 低合金鋼、鉄、銅 | 不規則な粉末形状、高い酸素含有量 | プレス・焼結工程 |

| プラズマ霧化 | チタン合金、超合金 | 非常に微細な球状粉末 | 積層造形 |

| 回転電極 | タングステン、モリブデン、タンタル | 制御された結晶粒構造 | フィラメント、切削工具 |

| カルボニルプロセス | 鉄、ニッケル、コバルト | 超微粒子高純度パウダー | 電子部品、磁石 |

| 電解 | 銅、ニッケル | 樹枝状薄片の形態 | 表面コーティング |

金属粉末 生産方法

異なる合金系から金属粉末を製造するために使用される様々な商業的方法がある。製造方法の選択は、以下のような要因に依存する:

- 合金材料の種類

- 純度要件

- 粒子径、形状、粒子構造など、ご希望の粉末特性

- 生産規模(トン/年

- パウダー最終用途

ここでは、金属粉末製造の最も一般的な工業プロセスを紹介する:

ガス噴霧プロセス

ガスアトマイズプロセスでは、溶融金属合金の流れは、通常窒素またはアルゴンの高圧ガスジェットによって分解される。金属流は微細な液滴に分解され、固化して粉末粒子になります。

ガスアトマイズ粉末は、球形で滑らかな表面形態を持つ。粒度分布は、プロセスパラメーターを調整することによって制御することができる。これは、チタン、アルミニウム、マグネシウム合金、ステンレス鋼、工具鋼、ニッケル超合金のような反応性材料に広く使用されている技術です。

| パラメータ | 説明 |

|---|---|

| 使用金属 | チタン合金、アルミニウム、マグネシウム、ステンレス鋼、工具鋼、超合金 |

| 粒子形状 | 球状の形態 |

| 粒子径 | 50 - 150 μm(代表値 |

| 純度 | 高濃度の不活性ガスで汚染を防止 |

| 酸素ピックアップ | 液体金属アトマイズと比較して最小 |

| 生産規模 | 年間最大1万トン |

水の霧化

水噴霧化では、溶融金属の流れに高速の水ジェットが当たる。急激な冷却により爆発が起こり、金属が微細な粒子に分解される。粉末は不規則な形状をしており、水との接触により酸素を多く含んでいる。

水アトマイズは、ステンレス鋼、合金鋼、鉄、銅の粉末をプレスや焼結タイプの用途に大量に製造するために使用される、より低コストのプロセスです。

| パラメータ | 説明 |

|---|---|

| 使用金属 | 炭素鋼、低合金鋼、ステンレス鋼、銅、鉄粉 |

| 粒子形状 | 爆発的な破水による不規則なモルフォロジー |

| 粒子径 | 10 - 300 μm(代表値 |

| 純度 | 低い位置で水と接触すると、酸素濃度が200~500ppm上昇する |

| 生産規模 | 非常に高く、年間5万トン以上 |

プラズマ霧化プロセス

プラズマアトマイズプロセスでは、プラズマトーチを使用して金属合金を溶解した後、ガスジェットによって微細な液滴に分解する。超高温のため、チタンアルミナイドのような反応性の高い元素をうまく霧化することができる。

The powders have a very spherical shape and narrow size distribution suitable for additive manufacturing methods like laser melting and electron beam melting.

| パラメータ | 説明 |

|---|---|

| 使用金属 | Titanium alloys, nickel superalloys, titanium aluminides |

| 粒子形状 | 球形度が高い |

| 粒子径 | 15 – 45 μm typical |

| 純度 | Very high purity due to melting under inert atmosphere |

| 生産規模 | Lower, about 100 – 1000 tons per year |

Rotating Electrode Process (REP)

In the rotating electrode process, a cylindrical metallic electrode is spun at high speeds in an evacuated chamber. It is melted using an electric arc and the molten metal droplets flung off through centrifugal forces cool to form powders.

REP powders have a grain structure and morphology ideal for hot extrusion into fine wires and rods for aerospace alloys like tungsten, molybdenum, tantalum.

| パラメータ | 説明 |

|---|---|

| 使用金属 | タングステン、モリブデン、タンタル |

| 粒子形状 | Irregular, controlled microstructure |

| 粒子径 | 45 – 150 μm typical |

| 純度 | Very high from processing under vacuum |

| 生産規模 | Small volumes of high value powders |

Electrode Induction Gas Atomization (EIGA)

The EIGA process uses induction heating to melt consumable electrode tips in an inert gas atmosphere. The droplets undergo secondary gas atomization by argon jets into fine spherical powders.

EIGA enables very high purity of reactive nickel superalloys for critical aerospace components through controlled melting and minimizing contamination.

| パラメータ | 説明 |

|---|---|

| 使用金属 | Nickel superalloys, titanium aluminides |

| 粒子形状 | 球形 |

| 粒子径 | 15 – 53 μm typical |

| 純度 | Extremely high, customized for critical alloys |

| 生産規模 | R&D/prototyping to mid-volume |

カルボニルプロセス

In the carbonyl process, metal is converted into a volatile carbonyl, which decomposes under controlled conditions to produce uniform, ultrafine metallic particles. This approach is suitable for producing highly pure iron, nickel and cobalt powders.

| パラメータ | 説明 |

|---|---|

| 使用金属 | 鉄、ニッケル、コバルト |

| 粒子形状 | Spherical to polyhedral |

| 粒子径 | 1 – 10 μm typical |

| 純度 | Extremely high 99.9%+ purity |

| 生産規模 | Up to 30,000 tons per year |

Other Powder Production Methods

Some other techniques used for specialty metal powder production include:

- Electrolytic Process: Used for producing irregular shaped copper and nickel powders with dendritic morphology by electro-deposition process

- Metal Reduction Processes: Reduction of metal oxides using hydrogen or carbon to produce titanium, zirconium, tungsten, molybdenum powders

- 機械的合金化: High energy ball milling to synthesize composite and nanostructured alloys

金属粉末 仕様

Critical quality attributes and specifications tested for metal powders depend on production method and end-use application but typically include:

Powder Chemistry

- Alloy composition using optical emission or X-ray fluorescence spectroscopy

- Minor alloying elements

- Impurity elements like oxygen, nitrogen, hydrogen

- Loss on ignition testing at high temperature

粒度分布

- Volume mean particle size

- Distribution widths like D10, D50, D90

Particle Shape Characterization

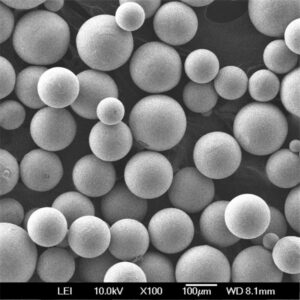

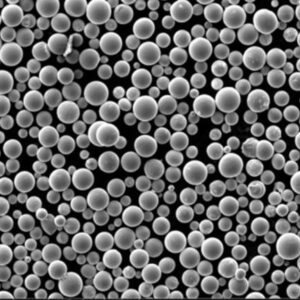

- Scanning electron microscopy for morphology

- Shape factors like aspect ratio and form factor

微細構造

- Phases present using X-ray diffraction

- Grain characteristics from imaging

粉末の特性

- 見かけ密度/タップ密度

- Flow rates through Hall flowmeter funnel tests

- Compressibility levels

Specification requirements for powders vary widely depending on end use in different applications:

| パラメータ | 金属射出成形(MIM) | アディティブ・マニュファクチャリング | Press & Sinter |

|---|---|---|---|

| 粒子径範囲 | 3 – 25 μm | 15 - 45 μm | 150 – 300 μm |

| Aspect ratio | 1 – 1.25 preferred | <1.5 spherical | Not critical |

| Oxygen levels | <1000 ppm | <500ppm | 2000 – 4000 ppm |

| 見かけ密度 | >2.5 g/cm3 | >2.8 g/cm3 | 2 – 3 g/cm3 |

| ホール流量 | 15 – 35 s/50g | 25~35秒/50g | >12 s/50g |

Characterization Methods

There are several analytical methods used to characterize the properties of metal powders essential to product performance:

Particle Size Analysis

Laser diffraction methods are most widely used to characterize the particle size distribution. This technique passes a laser beam through a dispersed powder sample which scatters light at an angle dependent on particle sizes. Computer analysis of the diffraction pattern provides detailed statistically relevant size distribution data within seconds.

Morphology and Surface Imaging

Scanning electron microscopy (SEM) provides high resolution images of powder particle shape, surface topographies and features at much higher magnification and depth of focus compared to optical microscopy.

SEM imaging is used to study particle rounding, satellite formation, surface smoothness and defects like porosity.

Density and Flow Property Measurement

Standard test methods have been established to quantify bulk behavior using:

- Hall flowmetry funnel to measure powder flow rates through an orifice

- Carney funnel to assess flowability by angle of repose

- Scott volumeter to determine tap density and compressibility

These methods help predict ease of handling, blending, die filling and spreading during component manufacturing.

X-ray Methods for Composition and Crystal Structure

- X-ray fluorescence spectroscopy accurately identifies and quantifies elemental composition of metals

- X-ray diffraction analyzes the atomic arrangements and phases present by diffraction peak patterns

金属粉末の用途

Some major end uses of engineering metal powders include:

アディティブ・マニュファクチャリング

Also known as 3D printing techniques like selective laser melting (SLM), direct metal laser sintering (DMLS) and electron beam melting (EBM) to build complex geometries from titanium, aluminum, stainless steel, superalloy, cobalt chrome powders.

金属射出成形(MIM)

Powders like stainless steels, titanium alloys and tool steels are combined with a binder, injection molded then sintered to manufacture small, complex parts at high volumes for lower costs.

粉末冶金プレスと焼結

Compacting and sintering iron, copper and alloy steel powders into high volume components like gears, bushings and magnets.

| 申し込み | 使用金属 | Key Property Needs |

|---|---|---|

| 積層造形 | Titanium alloys, nickel superalloys, aluminum, tool steel, stainless steel, cobalt chrome | Spherical morphology Good flowability High purity |

| 金属射出成形 | Stainless steel, titanium, tool steel, tungsten heavy alloys | Fine <25 μm powder Good packed density |

| プレスと焼結 | Iron, steel, stainless steel, copper | Cost effective powder Lubricant coatings |

There are also niche applications in areas like welding, diamond tools, electronics and surface coatings that use specialty metal powders.

サプライヤーと価格

Some leading global suppliers of various metal powders are:

| 会社概要 | 生産方法 | 材料 |

|---|---|---|

| サンドビック・オスプレイ | ガス噴霧 | チタン、アルミニウム、ニッケル合金 |

| エーピーアンドシー | プラズマ霧化 | Titanium aluminides, superalloys |

| カーペンター・テクノロジー | Gas, water atomization | Tool steels, stainless steels, alloys |

| ヘガネス | 水の霧化 | Iron, stainless steels |

| JFE Steel | 水の霧化 | ステンレス鋼粉末 |

| リオ・ティント | Aluminum powder | Carbonyl nickel and iron |

Pricing for metal powders varies widely by:

- Alloy material and composition

- 使用される製造方法

- Processing to achieve particle characteristics

- Purity levels and degree of contamination

- Purchase volumes – very high volume contracts bring lower pricing

Typical base prices per kilogram are:

| 素材 | 価格見積もり |

|---|---|

| ステンレス 316L | $12 – $30 per kg |

| アルミニウム AlSi10Mg | $15 – $45 per kg |

| チタン Ti-6Al-4V | $80 – $220 per kg |

| Nickel superalloy Inconel 718 | 1kgあたり$90~$250 |

| Specialty alloys for AM | $250 – $1000 per kg |

Prices go up significantly for highly customized particle size distributions, controlled oxygen and nitrogen levels below 100 ppm, and small lot purchases.

Advantages and Limitations of Powder Metallurgy

Benefits of Powder Metallurgy

- Ability to produce complex geometries not possible through casting or machining

- Near-net-shape manufacturing reduces material waste

- Higher performance metals and alloys can be used

- Consistent porosity structures not possible in ingot metallurgy

- Components can be mass customized

Limitations of Powder Production and Processing

- Capital investment for production and handling equipment is very high

- Increased surface area makes handling pyrophoric reactive powders risky

- Achieving high compaction densities can require high pressures

- Additional process steps compared to casting

- Portability of AM machines due to powder being LO/NO

Here is a quick comparison of powder metallurgy against the conventional casting process:

| パラメータ | 粉末冶金 | キャスティング |

|---|---|---|

| 複雑な形状 | ✅ Excellent for layered AM builds | Limited for typical castings |

| 機械的特性 | Can approach cast properties after Hot Isostatic Pressing | ✅ Predictable properties |

| サイクルタイム | Slower process for AM methods | ✅ Faster for volume production |

| 寸法精度 | Varies, depends on post-processing | Very good for precision investment castings |

| Equipment costs | Very high for industrial AM machines | ✅ Lower capital costs |

| Types of metals | Continually expanding options | ✅ Broadest selection |

よくあるご質問

Q: What is the typical particle size range used in metal 3D printing powders?

A: In powder bed technologies like selective laser melting (SLM) and electron beam melting (EBM), the optimal particle size range is 15-45 microns. Finer powders improve resolution but can be challenging to handle and process.

Q: What determines morphology of metal powders from different methods?

A: Production factors like intensity of melt stream breakdown forces from gas jets or water impacts and subsequent cooling rates determine particle shapes. Faster cooling produces irregular, dendritic particles while slower solidification (spherical atomization) enables smooth rounded structures.

Q: Why is high purity important for metal powders in additive manufacturing?

A: Impurities can cause defects, porosity issues, alter alloy microstructures, reduce density, affect performance under loads and temperatures – negatively impacting mechanical properties. Target oxygen levels below 500 ppm and nitrogen levels below 100 ppm have become typical.

Q: How are metal powders handled safely during transportation and storage?

A: Reactive metal powders are passivated to create oxidized surfaces minimizing flammability risk. Powders are sealed in drums under inert gases like argon instead of air during shipment to prevent ignition. Storage containers must be properly grounded. Personnel wear specialized PPE while handling.

Q: What are common powder characterization methods?

A: Hall flowmetry, tap density tests, pycnometry, LOI testing, spectrographic analysis, metallography and particle size distribution using laser or sieve techniques are vital to quantifying behavior, building quality process control for metal powder production and assessing batch suitability for given applications.