概要 モリブデン粉

Molybdenum powder refers to fine molybdenum particles in powder form used in various metallurgical, electronic, chemical, and industrial applications. Molybdenum has unique properties like high melting point, strength at high temperatures, corrosion resistance, thermal conductivity etc. that make it suitable for specialized uses.

モリブデンパウダーの主な詳細:

- Pure molybdenum or molybdenum alloys with other metals

- Main applications are metallurgy, electronics, chemicals, lubricants

- High purity levels from 99.5% to 99.9999% based on process

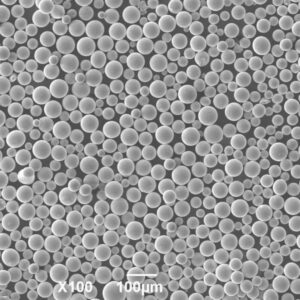

- Particle sizes ranging from 1 micron to 150 microns

- Multiple manufacturing methods yield different characteristics

- Properties like thermal conductivity leveraged across industries

- Pricing varies based on purity, size specs and purchase volumes

Molybdenum powder possesses properties that provide performance benefits making it a critical material in metal alloys, electronics, chemicals, lubricants and pigments globally.

Molybdenum Powder Compositions

Molybdenum powder is available in various compositions ranging from pure molybdenum to combinations with other elements to form alloy powders.

Pure Molybdenum Powder

Molybdenum content above 99.5% purity, with low level impurities.

Molybdenum Alloy Powders

| 合金 | 典型的な構成 |

|---|---|

| Mo-Cu | Mo 97%, Cu 3% |

| Mo-La2O3 | Mo 60-70%, La2O3 30-40% |

| Mo-Ni | Mo 40-60%, Ni 40-60% |

| Mo-TiC | Mo 70-80%, TiC 20-30% |

| Mo-TiB2 | Mo 60-80%, TiB2 20-40% |

| Mo-W | Mo 40-60%, W 40-60% |

These powder alloys leverage combined properties of molybdenum with other elements for enhanced performance in specific applications like electronics.

Molybdenum Powder Properties

Molybdenum powder offers a unique combination of chemical, electrical, thermal, and mechanical properties:

| プロパティ | 代表値 |

|---|---|

| 密度 | 10.2 g/cc |

| 融点 | 2,623°C |

| 熱伝導率 | 138 W/m-K |

| 電気抵抗率 | 5.5 μΩ-cm |

| coefficient of Thermal Expansion | 5.3 μm/m-°C |

| Maximum Working Temp | 1,600-2,000°C |

Its high temperature strength, corrosion resistance, thermal conductivity and other attributes provide advantages where performance under extreme conditions is necessary.

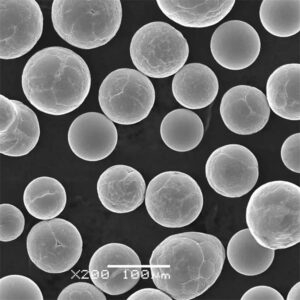

Key factors influencing molybdenum powder properties include:

- 純度グレード – directly impacts electrical, chemical and mechanical characteristics

- 粒子径 – smaller size increases surface area to volume ratio enhancing chemical reactivity

- 製造工程 – determines morphology, internal porosity and microstructure

- 合金元素 – tailored to achieve specific thermal, electrical or rheological properties

Property optimization and customization is possible for client applications through control of molybdenum powder composition and powder metallurgy techniques.

モリブデン粉末の用途

Some major application areas of molybdenum metal powders across industrial sectors include:

Metallurgical Additive

- Alloying element in stainless steels for corrosion resistance and high strength

- Improves hardenability, toughness and strength in tool steels

- Added to nickel and chromium superalloys for aircraft engines

Electronics & Electrical

- High current carrying capacity utilized in electron emitters and cathodes

- Component in advanced ceramic capacitors, ferroalloys and solar cell contacts

Pigments, Catalysts & Chemicals

- Precursor for molybdenum oxides used as pigments and catalysts

- Reagent in lubricant additives, dyes, organic synthesis, desulfurization etc.

Coatings & Joining

- Used as brazing alloy filler metal for high service temperature welding

- Applied in thermal spray protective coatings and metallization layers

The heat resistance, electrical conductivity and other useful characteristics make molybdenum indispensable across high performance products and advanced technologies.

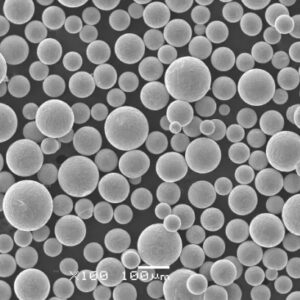

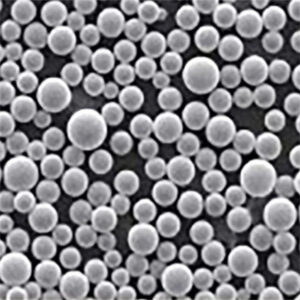

Molybdenum Powder Specifications

Commercial molybdenum powders for industrial uses are available under different specification grades classified according to:

| パラメータ | 典型的な範囲 |

|---|---|

| 純度 | 99.5% to 99.9999% |

| 粒子径 | 1 to 150 microns |

| 形 | 不規則、球形 |

| 見かけ密度 | 2 to 6 g/cc |

| タップ密度 | 4 to 10 g/cc |

American Society for Testing and Materials (ASTM) has defined reference standards for additive manufacturing use:

| スタンダード | Item | 基準 |

|---|---|---|

| ASTM B781 | 化学組成 | Elemental content percentages |

| ASTM B783 | Particle size classification | Micron and mesh range |

| ASTM B809 | Spherical powder specification | Purity, particle size distribution, apparent density |

These help define quality metrics and ensure buyers get molybdenum powder suitable for mission-critical applications. Custom particle dimensions, size distribution yields, shape uniformity, surface area, bulk densities, and impurity grades are possible through agreement with reputable manufacturers.

モリブデンパウダー Manufacturers and Prices

There are several global specialty metals producers providing pure molybdenum and molybdenum alloy powders for commercial uses. Some of the major suppliers are:

| 会社概要 | 本社 |

|---|---|

| H.C.スタルク | ドイツ |

| プランゼーグループ | オーストリア |

| Exploiter Molybdenum | 中国 |

| China Molybdenum Co. | 中国 |

| モリメット | チリ |

| JDC Moly | Korea |

Some Molybdenum Powder Cost Indications

| 純度 | メッシュサイズ | kgあたりの価格 |

|---|---|---|

| 99% | -325 Mesh | $40 – $55 |

| 99.5% | 1-5 Microns | $70 – $90 |

| 99.9% | 10-50 Microns | $100 – $140 |

| 99.95% | Spherical <45 μm | $140 – $170 |

Final pricing depends on exact material grade, particle characteristics, order volumes, supply chain logistics and market conditions. Powder metallurgy grade spherical molybdenum with high purity and controlled particle size distribution necessary for critical applications demands premiums.

モリブデンパウダー使用の長所と短所

Here is a comparative look at some of the advantages and disadvantages associated with molybdenum powder:

メリット

- Excellent high temperature strength for service over 2000°C

- Low coefficient of thermal expansion for dimensional stability

- High thermal and electrical conductivity for heat sinks

- Extremely corrosion resistant nature

- Tailor mechanical properties through alloy combinations

- Net-shape part fabrication simplicity with press and sinter

デメリット

- Relatively more expensive than substitute options

- Lower hardness and wear/abrasion resistance needing surface treatments in friction contacts

- Susceptible to oxygen contamination at higher processing temperatures

- Requires inert atmospheres or vacuum for metallurgical consolidation

- Exhibits poorer machinability relative to steels

- Lacks ductility for extensive cold forming operations

For niche applications where thermal stability, chemical resistance and electrical characteristics matter, molybdenum outperforms alternatives like tungsten or tantalum, offsetting higher base price for its differentiated performance.

Molybdenum Powder vs. Molybdenum Sheet

Molybdenum powder provides specific advantages in manufacturing and properties relative to molybdenum sheet, rod or wire forms:

Key Differences

| パラメータ | モリブデンパウダー | Molybdenum Sheet/Rod |

|---|---|---|

| 製造方法 | Atomization and milling | Casting and rolling |

| Size and Shape Control | 素晴らしい | 限定 |

| 寸法公差 | Tighter | Wider |

| Surface Finishes | Fine matte | Smooth lustrous |

| 機械的特性 | Isotropic fine grained | Anisotropic coarse |

| Net Shape Capability | Very good sintered parts | Extensive machining needed |

| 経済学 | Lower material utilization | Higher raw material efficiency |

The ability to press and sinter molybdenum powder into high performance parts very close to final dimensions + the flexibility around customized powder characteristics makes it attractive for numerous functional and structural component needs.

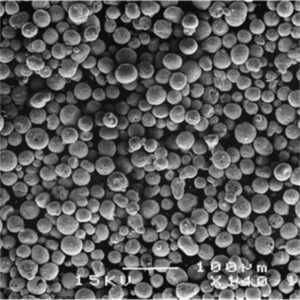

Thermal Spray with Molybdenum Powder

Thermal spray techniques like high velocity oxy-fuel (HVOF), plasma or arc spray are used to deposit molten or semi-molten molybdenum powder onto components to form highly adherent protective coatings.

Benefits of molybdenum metal spray:

- Wear resistance for friction and load bearing surfaces

- Electrical and thermal conductive surface layers

- Corrosion protection in chemical processing equipment

- Dimensional restoration of worn-out parts through build up

Common spray parameters for molybdenum powder:

| パラメータ | 典型的な範囲 |

|---|---|

| 粒子径 | 10~45ミクロン |

| Deposition Efficiency | 50 – 70% |

| Coating Thickness | 50 – 500 microns |

| Microhardnes | 350 – 600 HV |

| Bond Strength | > 69 MPa |

| Operating Temperature | 120°C to 260°C |

Molybdenum coatings are widely leveraged across oil & gas valves, aerospace seals, automotive bearings, plastic extrusion barrels, and electrical contacts in connectors owing to exceptional tribological characteristics.

よくあるご質問

Q: What industries use molybdenum powder for manufacturing purposes?

A: Major end-use segments are metallurgy, electronics, catalysts, aerospace, energy, coatings, and chemicals – leveraging properties like high temperature strength, thermal conductivity, electrical resistivity and corrosion resistance.

Q: What typical processes are employed for fabricating parts using molybdenum powder?

A: Main techniques are powder pressing followed by pressureless or pressure-assisted sintering. Powder injection molding and additive manufacturing are also emerging for complex geometries.

Q: What are common contaminants affecting quality of molybdenum powders?

A: Oxygen, carbon, sulfur and chlorine are detrimental impurities impairing utility in applications demanding high chemical purity like electronics. Stringent process controls during manufacturing are critical.

Q: Does molybdenum powder require special handling precautions?

A: Inert gas blanketing, vacuum packing and low humidity storage is necessary for high purity fine powders prone to oxidation at elevated temperatures reached during processing.

Q: What coatings can be sprayed using molybdenum powders?

A: Besides pure molybdenum, composite variations like Mo-Cu, Mo-NiCrBSi, Mo-NiCrFeSiB and carbide coatings blended with nickel or cobalt chrome matrices containing molybdenum provide enhanced functional characteristics.

Q: What testing methods help characterize molybdenum powders?

A: Chemical analysis verifies composition purity levels through techniques like ICP-MS, XRF or LECO analysis. Physical attributes like particle size distribution, shape factors, apparent density and tap density help optimize powder morphology.

結論

Molybdenum metal powder, with its unique electrical, thermal, and mechanical properties, provides differentiated performance making it indispensable for critical applications like aerospace engines, electronics, furnace components and metal alloys where reliability under extreme conditions is vital.

Continual development of purer compositions with precisely engineered particle dimensions, size distribution fractions, shapes, density parameters and microstructures tailored to specific end-uses expands utility across more sectors and technologies.

Enhanced manufacturing methods combined with strong industry demand strongly position fine モリブデン粉 to see robust long term growth owing to the material’s distinctive capabilities.