銅 99.95 粉末

Cu 99.95 粉末は、電解タフピッチ (ETP) 銅粉末とも呼ばれ、最小 99.95% の銅を含む高純度の銅粉末です。優れた電気伝導性および熱伝導性と、優れた機械的特性を兼ね備えています。主な用途には、電気接点、ブラシ、溶接製品、ろう付け、摩擦材、ダイヤモンド工具などがあります。

低いMOQ

さまざまなニーズに対応するため、最低注文数量を少なくしています。

OEM & ODM

顧客独自のニーズに応えるため、カスタマイズされた製品とデザインサービスを提供する。

十分な在庫

迅速な注文処理と、信頼できる効率的なサービスの提供。

顧客満足度

顧客満足を核とした高品質の製品を提供する。

この商品を共有する

目次

Overview of Cu 99.95 Powder

Cu 99.95 powder, also referred to as electrolytic tough pitch (ETP) copper powder, is a high purity copper powder containing a minimum of 99.95% copper.

It has excellent electrical and thermal conductivity combined with good mechanical properties. Key applications include electrical contacts, brushes, welding products, brazing, friction materials and diamond tools.

Some key properties and advantages of Cu 99.95 powder include:

Cu 99.95 Powder Properties and Characteristics

| プロパティ | 詳細 |

|---|---|

| 構成 | 99.95% minimum copper |

| 密度 | 8.94 g/cc |

| 粒子形状 | 不規則、角張っている |

| サイズ範囲 | 2-150 microns |

| 見かけ密度 | 最大 50% の真密度 |

| 流動性 | Low to moderate |

| 導電率 | Excellent electrical and thermal conductivity |

| 焼結性 | Good sinterability in H2 atmosphere |

| 純度 | High purity copper |

Cu 99.95 provides an optimal balance of conductivity, mechanical properties, sintering characteristics and cost for fabrication of parts via pressing and sintering.

Cu 99.95 Powder Composition

Typical composition of Cu 99.95 powder:

Cu 99.95 Powder Composition

| エレメント | 重量 % |

|---|---|

| 銅(Cu) | 99.95% min |

| 酸素 (O) | 0.05%最大 |

| 鉛(Pb) | 0.005% max |

| その他の不純物 | 0.005% max |

- Copper provides excellent conductivity and ductility

- Oxygen present as impurity affects conductivity and sintering

- Lead and other impurities carefully controlled

High copper content gives excellent electrical and thermal conductivity combined with good mechanical properties after sintering.

Cu 99.95 Powder Physical Properties

Cu 99.95 Powder Physical Properties

| プロパティ | 価値観 |

|---|---|

| 密度 | 8.94 g/cc |

| 融点 | 1083°C |

| 熱伝導率 | 400 W/mK |

| 電気抵抗率 | 1.72 μΩ-cm |

| 再結晶温度 | 200-300°C |

| キュリー温度 | -269°C |

- High density compared to iron and aluminum

- Excellent thermal conductivity for heat removal

- Low electrical resistivity provides high conductivity

- Resistivity increases above Curie temperature

- Recrystallization enables sintering and improves ductility

The physical properties make Cu 99.95 suitable for applications like electrical contacts and brushes requiring high conductivity.

Cu 99.95 Powder Mechanical Properties

Cu 99.95 Powder Mechanical Properties

| プロパティ | 価値観 |

|---|---|

| 引張強さ | 220-340 MPa |

| 降伏強度 | 70-190 MPa |

| 伸び | 35-60% |

| 硬度 | 45-90 HB |

| 弾性係数 | 110-130 GPa |

| 圧縮強度 | 500-700 MPa |

- Good combination of strength and high ductility

- Relatively low hardness and high malleability

- Moderate strength levels compared to high strength alloys

- Properties depend on factors like porosity and grain size

The mechanical properties make Cu 99.95 suitable for softer conductive components that require deformation and compressive strength.

Cu 99.95 Powder Applications

Typical applications of Cu 99.95 powder include:

Cu 99.95 Powder Applications

| 産業 | 応用例 |

|---|---|

| Electrical and electronics | Contacts, connectors, brushes, RF shielding |

| 自動車 | Brushes, bushings, bearings |

| インダストリアル | Welding electrodes, casting molds, metal matrix composites |

| 製造業 | Brazing and soldering, tooling components |

| Friction products | Brake pads, clutch discs |

いくつかの具体的な用途:

- Sliding electrical contacts and brushes

- Structural components requiring conductivity

- Jewelry crafting and artisanal products

- Diamond tools with copper metal matrix

- Welding rods and brazing paste formulations

- Mold liners for casting reactive alloys

The excellent balance of conductivity, mechanical properties, formability and cost make Cu 99.95 suitable for this broad range of applications.

Cu 99.95 Powder Specifications

Key specifications for Cu 99.95 powder include:

Cu 99.95 Powder Specifications

| スタンダード | 説明 |

|---|---|

| ASTM B602 | Standard specification for undeformed, wrought, electrolytic tough pitch copper |

| JIS H3125 | Electrolytic copper and copper alloy powders |

| ISO 3497 | Copper powders for general purposes |

| ASTM B Guidance | Apparent density, flow rate, particle size distribution |

これらの標準では以下が定義されています。

- Minimum 99.95% copper content

- Limits on impurities like O, Pb

- Required powder characteristics

- Production method – electrolytic process

- 許容可能な粒度分布

- Testing methods for powder properties

Compliance ensures the powder meets the required purity and properties for the intended application.

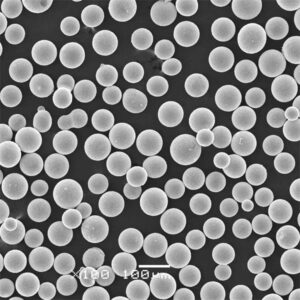

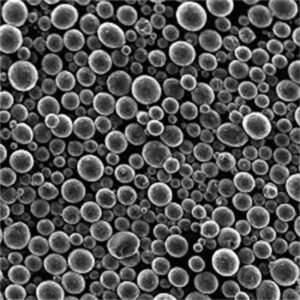

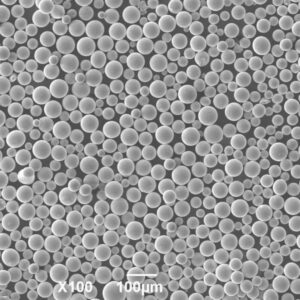

Cu 99.95 Powder Particle Sizes

Cu 99.95 Powder Particle Size Distribution

| 粒子径 | 特徴 |

|---|---|

| 2-20 microns | Very fine powder used in microelectronics |

| 5-30 microns | Fine powder for sintering and injection molding |

| 15-150ミクロン | Coarse powder suitable for pressing |

- Finer powder sizes provide greater sintered density

- Coarse powder has better flowability for automated filling

- Size range tailored based on part requirements

- Both irregular and spherical powder shapes are available

Controlling particle size distribution allows optimizing pressing characteristics, sintered density and properties.

Cu 99.95 Powder Apparent Density

Cu 99.95 Powder Apparent Density

| 見かけ密度 | 詳細 |

|---|---|

| 最大 50% の真密度 | 不規則な粉末形態の場合 |

| 3.5-5.0 g/cc typical | Compacts to nearly full density after pressing and sintering |

- より高い見掛け密度により、粉末の流れと圧縮性が向上します

- 不規則な形態により最大充填密度が制限される

- 最適化された球状粉末により60%まで可能

- High green density after compaction enables good sintering

Higher apparent density improves manufacturing productivity and part quality.

Cu 99.95 Powder Production Method

Cu 99.95 Powder Production

| 方法 | 詳細 |

|---|---|

| 電解 | Copper cathodes dissolved anodically into Cu+ ions which are deposited onto stainless steel cathodes |

| 研削 | Coarse powder broken down and classified into specific size ranges |

| アニーリング | Softens the powder particles and improves compressibility |

| Reducing atmosphere | Prevents oxidation of particles during production |

- Automated electrolytic process allows high purity powder production

- Grinding and sieving provides controlled particle size distribution

- Annealing enables easy compaction into high density parts

- Strict process control ensures reliable and consistent powder quality

Cu 99.95 Powder Pricing

Cu 99.95 Powder Pricing

| ファクター | 価格への影響 |

|---|---|

| 純度グレード | 高純度グレードはより高価 |

| 粒子径 | Ultrafine is more expensive |

| 注文数量 | Price decreases with bulk orders |

| 製造方法 | Additional processing increases cost |

| パッケージング | Special packaging like vacuum sealing adds cost |

参考価格

- Cu 99.95 fine powder: $8-12 per kg

- Cu 99.95 coarse powder: $7-10 per kg

- Reduced pricing applicable for bulk orders >500 kg

Pricing depends on order volume, particle size, production method, purity level and packaging.

Cu 99.95 Powder Suppliers

Cu 99.95 Powder Suppliers

| 会社概要 | 所在地 |

|---|---|

| カイメラ・インターナショナル | アメリカ |

| GGP Metalpowder | ドイツ |

| アメリカン・ケメット・コーポレーション | アメリカ |

| 上海CNPC粉末材料 | 中国 |

| Nuclead | フランス |

| Libo Metals | 中国 |

サプライヤーの選択要素:

- Powder purity levels and grades offered

- 生産能力とリードタイム

- Average particle size ranges

- Customization of size distribution

- Packaging and minimum order quantity

- 注文量に応じた価格設定

- Compliance with international specifications

Cu 99.95 Powder Handling and Storage

Cu 99.95 Powder Handling

| 推薦 | 理由 |

|---|---|

| 吸入を避ける | 呼吸器への刺激の可能性 |

| Use masks, gloves | Prevent ingestion |

| 十分な換気の確保 | 浮遊粒子を減らす |

| 発火源を避ける | 可燃性粉塵の危険性 |

| 静電気防止手順に従ってください | 静電気放電による火災の防止 |

| 火花の出ない工具を使用する | Avoid ignition during handling |

| Store in cool, dry location | 酸化と吸湿を防ぐ |

ストレージに関する推奨事項

- Store in sealed containers away from acids or chlorides

- 気温を27℃以下に保つ

- Limit exposure to:

- Oxidizing acids like nitric acid

- Hot sulfuric acid

- Hydrogen sulfide

- Ammonia solutions

- Chlorinated hydrocarbons

Proper handling and storage helps preserve purity and prevent reactivity or fire hazards.

Cu 99.95 Powder Inspection and Testing

Cu 99.95 Powder Testing

| テスト・タイプ | 詳細 |

|---|---|

| 化学分析 | ICP analysis to verify composition |

| 粒度分布 | レーザー回折分析 |

| 見かけ密度 | ASTM B212に準拠したホール流量計テスト |

| 粉末形態 | SEMイメージング |

| タップ密度 | Measured after mechanical tapping |

| 流量分析 | 指定ノズルを通る重力流量 |

Stringent testing ensures the powder meets chemical, physical and morphological specifications required for the application.

Cu 99.95 Powder Pros and Cons

Advantages of Cu 99.95 Powder

- Excellent electrical and thermal conductivity

- Good ductility and malleability

- Cost-effective compared to pure silver or gold

- Good corrosion resistance and bio-compatibility

- Easy to sinter and compress into high density parts

- リサイクル可能で環境に優しい

Limitations of Cu 99.95 Powder

- Lower strength than high strength alloys

- 適度な高温耐酸化性

- Heavy compared to magnesium and aluminum

- Not suitable for highly stressed load-bearing components

- Surface tarnishing over time if uncoated

- Restricted food contact applications

Comparison With CuCrZr Powder

Cu 99.95 vs CuCrZr Powder

| パラメータ | Cu 99.95 | CuCrZr |

|---|---|---|

| 密度 | 8.94 g/cc | 8.8 g/cc |

| 強さ | 220-340 MPa | 450~650MPa |

| 導電率 | 素晴らしい | 中程度 |

| 熱安定性 | フェア | 素晴らしい |

| コスト | 低い | 高い |

| 用途 | Electrical, thermal,moderate load | High strength structural parts |

- Cu 99.95 has better conductivity and lower cost

- CuCrZr provides higher strength and thermal stability

- Cu 99.95 suitable for softer conductive components

- CuCrZr preferred for high load structural parts

Cu 99.95 Powder FAQs

Q: What are the main applications of Cu 99.95 powder?

A: The main applications include electrical contacts, brushes, welding products, diamond tools, brazing alloys, friction materials, and metal matrix composites. It is widely used in electronics, automotive and industrial products.

Q: What affects the properties of Cu 99.95 powder parts?

A: Key factors affecting properties are apparent density, amount of lubricant, compacting pressure, sintering time/temperature, powder composition, particle size distribution, and presence of impurities.

Q: What precautions should be taken when handling Cu 99.95 powder?

A: Recommended precautions include avoiding inhalation, ensuring proper ventilation, wearing protective gear, controlling static discharge, using non-sparking tools, avoiding ignition sources, and storing in a cool, dry location in sealed containers.

Q: How does Cu 99.95 powder differ from bronze and brass powders?

A: Bronze and brass are copper alloys with tin and zinc while Cu 99.95 is pure copper. It has higher conductivity but lower strength than bronze or brass. Cu 99.95 is more cost-effective.

Met3DPについて

製品カテゴリー

ホットセール

中国・青島に本社を置く積層造形ソリューションの大手プロバイダー。