純アルミニウム粉

純アルミニウム粉末には99%以上のアルミニウム含有量が含まれています。低密度でありながら、優れた延性、導電性、耐食性を備えています。

低いMOQ

さまざまなニーズに対応するため、最低注文数量を少なくしています。

OEM & ODM

顧客独自のニーズに応えるため、カスタマイズされた製品とデザインサービスを提供する。

十分な在庫

迅速な注文処理と、信頼できる効率的なサービスの提供。

顧客満足度

顧客満足を核とした高品質の製品を提供する。

この商品を共有する

目次

純アルミニウムパウダーの概要

純アルミニウム粉末には99%以上のアルミニウム含有量が含まれています。低密度でありながら、優れた延性、導電性、耐食性を備えています。

Key properties and advantages of pure aluminum powder include:

Pure Aluminum Powder Properties and Characteristics

| プロパティ | 詳細 |

|---|---|

| 構成 | 99% or higher Al content |

| 密度 | 2.7 g/cc |

| 粒子形状 | 球形、不規則 |

| サイズ範囲 | 1~150ミクロン |

| 見かけ密度 | 最大 50% の真密度 |

| 導電率 | Excellent electrical and thermal conductivity |

| 耐食性 | Good due to protective oxide layer |

Pure aluminum powder is suitable for applications like thermite welding, diamond tools, conductive coatings, pyrotechnics, and metal injection molding.

Pure Aluminum Powder Composition

Typical composition of pure aluminum powder:

Pure Aluminum Powder Composition

| エレメント | 重量 % |

|---|---|

| アルミニウム(Al) | 99%分 |

| ケイ素 (Si) | 最大0.5% |

| 鉄(Fe) | 最大0.5% |

| 銅(Cu) | 0.05%最大 |

| マンガン (Mn) | 0.05%最大 |

| マグネシウム (Mg) | 0.05%最大 |

| その他の不純物 | 0.05%最大 |

- Aluminum provides low density, ductility and conductivity

- Impurity levels of other elements are carefully controlled

- High aluminum purity provides optimal electrical and thermal conductivity

The high aluminum content ensures excellent conductivity combined with good corrosion resistance and moderate strength.

Pure Aluminum Powder Physical Properties

Pure Aluminum Powder Physical Properties

| プロパティ | 価値観 |

|---|---|

| 密度 | 2.7 g/cc |

| 融点 | 660°C |

| 熱伝導率 | 237 W/mK |

| 電気抵抗率 | 2.65 μΩ-cm |

| CTE | 23.1 x 10^-6 /K |

| Reflectivity | 87% at 400 nm wavelength |

- Very low density compared to most metals

- High reflectivity and thermal conductivity

- Low electrical resistivity provides high conductivity

- CTEが比較的高いため、設計上の配慮が必要

- Maintains strength up to moderately high temperatures

The properties make pure aluminum suitable for lightweight applications needing electrical/thermal conductivity.

Pure Aluminum Powder Mechanical Properties

Pure Aluminum Powder Mechanical Properties

| プロパティ | 価値観 |

|---|---|

| 引張強さ | 90-100 MPa |

| 降伏強度 | 35-45 MPa |

| 伸び | 35-40% |

| 硬度 | 25-35 HB |

| 疲労強度 | 50-90 MPa |

| せん断強度 | 60-65 MPa |

- Relatively low tensile and yield strength

- Very high elongation provides excellent ductility

- Low hardness compared to most metals

- High fatigue strength suited for cyclic loading

- Properties can be enhanced through alloying additions

The properties make pure aluminum suitable for soft, ductile applications requiring conductivity and formability.

Pure Aluminum Powder Applications

Typical applications of pure aluminum powder include:

Pure Aluminum Powder Applications

| 産業 | 用途 |

|---|---|

| Thermite welding | Rail welding, metal joining |

| 積層造形 | Low strength components |

| Explosives and pyrotechnics | Thermite compositions |

| Powder coatings | Conductive and resistant coatings |

| Diamond tools | Metal matrix with diamond particles |

| 花火 | Fuel and pyrotechnic compositions |

いくつかの具体的な製品の用途

- Thermite mixtures for in-situ metal joining and welding

- Low melting point casting alloys

- Electrically conductive coatings and RF shielding

- Aluminum-diamond tools for stone cutting

- Flash powder and pyrotechnic compositions

- Metal injection molding of non-structural parts

The ductility, conductivity and reactivity make pure aluminum suitable for these niche applications.

Pure Aluminum Powder Specifications

Key specifications for pure aluminum powder include:

Pure Aluminum Powder Specifications

| スタンダード | 説明 |

|---|---|

| ASTM B787 | Standard for pure aluminum powders |

| ASTM B859 | Specs for aluminum and aluminum alloy powders |

| DIN 1718-1 | Designation system for aluminum and aluminum alloys |

| GJB320B | Chinese military standard for aluminum and aluminum alloy powders |

これらを定義する:

- Minimum 99% aluminum content

- Limits on impurities like Fe, Si

- Powder characteristics like apparent density and particle size distribution

- Approved production methods like atomization

- Sampling and testing protocols

Meeting the standards ensures suitability for applications needing high purity aluminum powder.

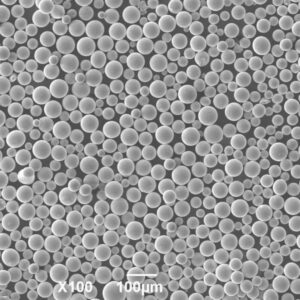

Pure Aluminum Powder Particle Sizes

Pure Aluminum Powder Particle Size Distribution

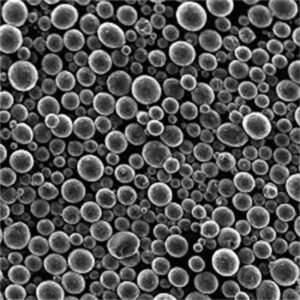

| サイズ | 特徴 |

|---|---|

| 1~10ミクロン | Ultrafine grade used in printing pastes |

| 10~45ミクロン | Fine grade suitable for coatings, pressing |

| 45~150ミクロン | Coarse grade offers better flowability |

- Finer sizes provide a smooth finish and high reactivity

- Coarser powder has improved flow for automated processing

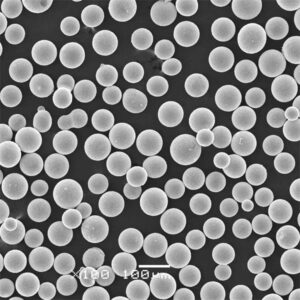

- Both spherical and irregular particle shapes are available

- Size distribution depends on targeted use

Controlling particle size distribution optimizes processing behavior, density, reactivity, and finish.

Pure Aluminum Powder Apparent Density

Pure Aluminum Powder Apparent Density

| 見かけ密度 | 詳細 |

|---|---|

| 最大 50% の真密度 | 不規則な形状の粉末用 |

| 1.3-1.7 g/cc | Higher for spherical powder |

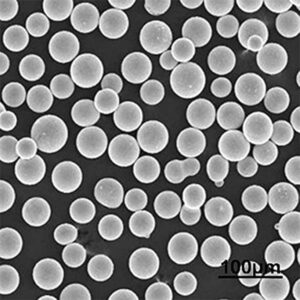

- Spherical powder shape provides higher apparent density

- Irregular particles have lower density around 30-40%

- Higher density improves powder flow and compactibility

- 最適化された球状粉末により60%まで可能

見かけの密度が高いほど、製造の生産性と部品の品質が向上します。

Pure Aluminum Powder Production

Pure Aluminum Powder Production

| 方法 | 詳細 |

|---|---|

| 霧化 | Molten aluminum stream broken into fine droplets that solidify into powder |

| Ball milling | Mechanical milling classifies coarse powder into fine powder |

| アニーリング | Removes internal stresses and improves powder compressibility |

| ふるい分け | 粉体を粒度別に分級 |

- Atomization allows large volume production with controlled particle sizes

- Milling provides lower cost size reduction of coarse powder

- Annealing and sieving provide customized powder sizes and shapes

Combination of methods produces high purity aluminum powder with application-specific characteristics.

Pure Aluminum Powder Pricing

Pure Aluminum Powder Pricing

| ファクター | 価格への影響 |

|---|---|

| 純度 | 高純度グレードはより高価 |

| 粒子径 | 超微粒子粉末は高価です |

| 注文量 | Bulk orders get discounted pricing |

| 製造方法 | 複雑な方法はコストを増加させる |

| パッケージング | Special packaging adds cost |

参考価格

- Fine pure aluminum powder: $3-6 per kg

- Coarse pure aluminum powder: $2-4 per kg

- Large volume pricing can be up to 30% lower

Pricing depends on purity, particle size, order quantity, production method and customization requirements.

Pure Aluminum Powder Suppliers

Pure Aluminum Powder Suppliers

| 会社概要 | 所在地 |

|---|---|

| Advanced Chemical Company | アメリカ |

| ミクロン金属 | アメリカ |

| Baohua Metal Materials | 中国 |

| Hengxing Metallurgical | 中国 |

| Shanghai ShuiDing Powder Material | 中国 |

| リード・アドバンスト・マテリアルズ | アメリカ |

サプライヤーの選択要素:

- Purity levels and grades available

- 生産能力とリードタイム

- Average particle size ranges

- Customization of particle distribution

- 梱包オプション

- Pricing levels based on order quantities

- Compliance with international standards

Pure Aluminum Powder Handling and Storage

Pure Aluminum Powder Handling

| 推薦 | 理由 |

|---|---|

| Use proper ventilation | Avoid concentrated dust environment |

| Employ grounding systems | Prevent static discharge during handling |

| Limit moisture exposure | Prevents oxidation of particles |

| 安全なプロトコルに従う | 健康と火災の危険を減らす |

| 発火源を避ける | Flammable powder risk |

| 火花の出ない工具を使用する | 発火の可能性を防ぐ |

ストレージに関する推奨事項

- Store in dry, inert sealed containers

- Maintain storage temperatures below 27°C

- Limit exposure to oxidizers like nitric acid

Proper precautions during handling and storage help preserve purity and prevent oxidation or ignition risks.

Pure Aluminum Powder Inspection and Testing

Pure Aluminum Powder Testing

| テスト | 詳細 |

|---|---|

| 化学分析 | XRF or ICP testing verifies composition |

| 粒度分布 | レーザー回折分析 |

| 見かけ密度 | ASTM B212規格によるホール流量計試験 |

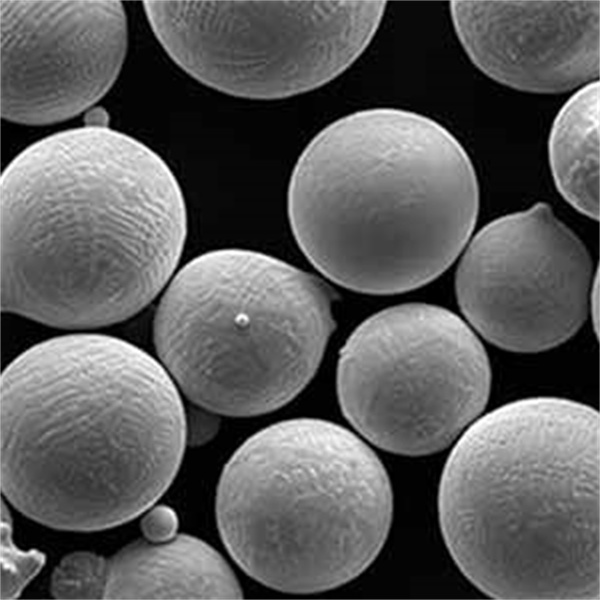

| 粉末形態 | 粒子形状のSEMイメージング |

| 流量分析 | 指定された漏斗を通過する重力流量 |

| 水分測定 | 乾燥減量試験 |

Testing ensures the powder meets the required purity levels, particle characteristics, density specifications, morphology and flowability per applicable standards.

Pure Aluminum Powder Pros and Cons

Advantages of Pure Aluminum Powder

- Low density provides lightweight properties

- Excellent electrical and thermal conductivity

- 良好な耐食性

- High ductility and excellent formability

- リサイクル可能で環境に優しい

- Cost-effective compared to other conductive powders

Limitations of Pure Aluminum Powder

- Low strength limits load bearing structural applications

- Moderate high temperature mechanical strength

- Requires protective coatings in corrosive environments

- Sensitive to contamination from moisture and other powders

- 発火性があるため、取り扱いには注意が必要

- Gradually oxidizes over time if uncoated

Comparison With Al-Mg Alloy Powder

Pure Al vs Al-Mg Alloy Powder

| パラメータ | ピュア・アル | Al-Mg |

|---|---|---|

| 密度 | 2.7 g/cc | 2.7 g/cc |

| 強さ | 90-100 MPa | 150-220 MPa |

| 導電率 | 素晴らしい | グッド |

| 耐食性 | グッド | 素晴らしい |

| コスト | 低い | 高い |

| 用途 | Thermite welding, pyrotechnics | Structural components |

- Pure Al offers better conductivity and lower cost

- Al-Mg alloy provides higher strength

- Pure Al suited for electrical applications and pyrotechnics

- Al-Mg preferred for structural lightweight components

Pure Aluminum Powder FAQs

Q: What are the main applications of pure aluminum powder?

A: Main applications include thermite welding, conductive coatings, pyrotechnic compositions, diamond tools, metal injection molding of non-structural parts, and low-melting casting alloys.

Q: What precautions should be taken when working with pure aluminum powder?

A: Recommended precautions include proper ventilation, avoiding ignition sources, explosion-proof equipment, grounding systems, non-sparking tools, protective gear, safe protocols, and inert storage sealed away from contaminants.

Q: How does pure aluminum powder differ from aluminum alloy powders?

A: Pure aluminum has 99% or higher Al content while alloy powders contain other elements like magnesium, silicon, zinc. Pure Al offers high conductivity but lower strength than alloys.

Q: What affects the properties of pure aluminum powder components?

A: Key factors are apparent density, particle size distribution, compaction pressure, sintering parameters, impurities, and final part porosity.

Met3DPについて

製品カテゴリー

ホットセール

中国・青島に本社を置く積層造形ソリューションの大手プロバイダー。