純銅パウダー

純銅粉には99.5%以上の銅含有量が含まれています。優れた熱伝導性および電気伝導性と、優れた耐食性、はんだ付け性、生体適合性を兼ね備えています。

低いMOQ

さまざまなニーズに対応するため、最低注文数量を少なくしています。

OEM & ODM

顧客独自のニーズに応えるため、カスタマイズされた製品とデザインサービスを提供する。

十分な在庫

迅速な注文処理と、信頼できる効率的なサービスの提供。

顧客満足度

顧客満足を核とした高品質の製品を提供する。

この商品を共有する

目次

Overview of Pure Copper Powder

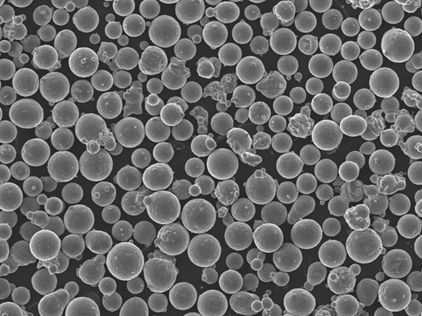

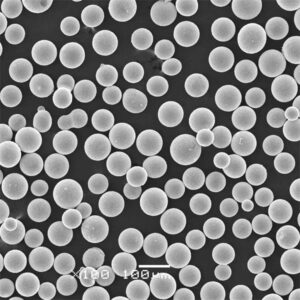

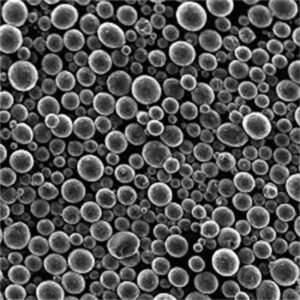

純銅粉には99.5%以上の銅含有量が含まれています。優れた熱伝導性および電気伝導性と、優れた耐食性、はんだ付け性、生体適合性を兼ね備えています。

Key properties and advantages of pure copper powder:

Pure Copper Powder Properties and Characteristics

| プロパティ | 詳細 |

|---|---|

| 構成 | 99.5% or higher copper content |

| 密度 | 8.94 g/cc |

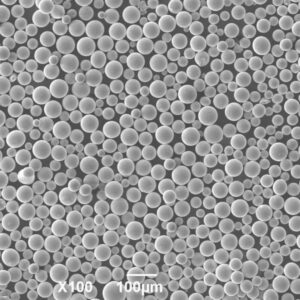

| 粒子形状 | 球形、不規則 |

| サイズ範囲 | 1~150ミクロン |

| 見かけ密度 | 最大 50% の真密度 |

| 導電率 | Excellent, second only to silver |

| Solderability | Excellent due to oxidation resistance |

| 生体適合性 | High, safe for food contact |

Pure copper powder is ideal for applications like welding products, brazing alloys, friction materials, diamond tools, electrical contacts, and metal injection molding.

Pure Copper Powder Composition

Typical composition of pure copper powder:

Pure Copper Powder Composition

| エレメント | 重量 % |

|---|---|

| 銅(Cu) | 99.5%分 |

| 酸素 (O) | 0.05%最大 |

| 鉛(Pb) | 0.005% max |

| その他の不純物 | 0.005% max |

- Copper provides excellent conductivity and corrosion resistance

- Oxygen present as impurity affects conductivity and sintering

- Lead and other impurities carefully controlled

High copper content, low oxide, and minimal impurities result in excellent electrical and thermal conductivity combined with good mechanical properties.

Pure Copper Powder Physical Properties

Pure Copper Powder Physical Properties

| プロパティ | 価値観 |

|---|---|

| 密度 | 8.94 g/cc |

| 融点 | 1083°C |

| 熱伝導率 | 400 W/mK |

| 電気抵抗率 | 1.72 μΩ-cm |

| 再結晶温度 | 200-300°C |

| キュリー温度 | -269°C |

- High density compared to magnesium or aluminum

- Excellent thermal conductivity for heat dissipation

- Low electrical resistivity provides high conductivity

- Recrystallization enables sintering and improves ductility

- Resistivity increases above Curie point

These properties make pure copper suitable for highly conductive components like electrical contacts and brushes.

Pure Copper Powder Mechanical Properties

Pure Copper Powder Mechanical Properties

| プロパティ | 価値観 |

|---|---|

| 引張強さ | 220-340 MPa |

| 降伏強度 | 69-172 MPa |

| 伸び | 35-60% |

| 硬度 | 45-90 HB |

| 弾性係数 | 110-130 GPa |

| 圧縮強度 | 500-700 MPa |

- Good combination of strength and very high ductility

- Relatively low hardness and high malleability

- Moderate strength compared to high strength alloys

- Properties depend on factors like porosity and grain size

The properties make pure copper suitable for soft, highly conductive components requiring good deformation and compressive strength.

Pure Copper Powder Applications

Typical applications of pure copper powder include:

Pure Copper Powder Applications

| 産業 | 用途 |

|---|---|

| Electricals | Contacts, brushes, welding electrodes |

| エレクトロニクス | Conductive adhesives, RF shielding |

| 自動車 | Brushes, bushings, bearings |

| インダストリアル | Diamond tools, casting molds |

| 製造業 | Brazing alloys, powder metallurgy |

| Friction products | Brake pads, clutch discs |

いくつかの具体的な製品の用途

- Sliding electrical contacts and brushes

- Heat sinks and thermal management components

- Welding rods, brazing pastes, and solder filler metal

- Metal matrix composites like diamond tools

- Net shape components made via metal injection molding

- Pump bushings, impellers, and other wear parts

The high conductivity, corrosion resistance, bio-compatibility and moderate strength make pure copper suitable for this diverse range of electrical, thermal, and moderate wear applications across all industries.

Pure Copper Powder Specifications

Key specifications for pure copper powder include:

Pure Copper Powder Specifications

| スタンダード | 説明 |

|---|---|

| ASTM B602 | Specification for high purity electrolytic copper powder |

| JIS H2111 | Specs for electrolytic copper and copper alloy powders |

| ISO 3497 | Specification for general purpose copper powders |

| ASTM B243 | Guidance on apparent density and flow rate |

これらを定義する:

- Minimum 99.5% copper content

- Limits on impurities like oxygen and lead

- Required powder characteristics

- Apparent density and flow rate

- Approved production method – electrolytic

- Sampling and testing protocols

Meeting these specifications ensures suitability for applications needing high thermal and electrical conductivity combined with good mechanical properties.

Pure Copper Powder Particle Sizes

Pure Copper Powder Particle Size Distribution

| サイズ | 特徴 |

|---|---|

| 1~10ミクロン | Ultrafine grade used in microelectronics |

| 10-30 microns | Fine grade suitable for sintering |

| 30-150 microns | Coarse grade has good flow for pressing |

- Finer sizes provide higher sintered density

- Coarser powder has improved flowability

- Size range tailored based on targeted application

- Both spherical and irregular shapes available

Controlling particle size distribution optimizes pressing behavior, sintered density and final part properties.

Pure Copper Powder Apparent Density

Pure Copper Powder Apparent Density

| 見かけ密度 | 詳細 |

|---|---|

| 最大 50% の真密度 | 不規則な粉末形態の場合 |

| 3.5-5.0 g/cc typical | 梱包密度が高いほど改善される |

- 見掛け密度が高いため、粉体の流動性と圧縮性が向上する

- 不規則な形態により最大充填密度が制限される

- Values up to 60% achievable with spherical powder

- High apparent density enables easier compaction

Higher apparent density leads to more efficient powder pressing and sintering to full density.

Pure Copper Powder Production

Pure Copper Powder Production

| 方法 | 詳細 |

|---|---|

| 電解 | Copper cathodes dissolved anodically into Cu+ ions and deposited on stainless steel cathodes |

| Ball milling | Coarse powder broken down and classified into specific sizes |

| アニーリング | Softens the powder particles and improves compressibility |

| Reducing atmosphere | Prevents oxidation of particles during production |

- Automated electrolytic process allows large scale production

- Milling and sieving provides controlled particle size distribution

- Annealing facilitates pressing and handling

- Strict process control ensures high purity and repeatable quality

Pure Copper Powder Pricing

Pure Copper Powder Pricing

| ファクター | 価格への影響 |

|---|---|

| 純度グレード | 純度が高くなるとコストが増加します |

| 粒子径 | 超微粉はより高価 |

| 注文数量 | Bulk orders have lower per unit pricing |

| 製造方法 | Additional processing increases cost |

| パッケージング | Special packaging like vacuum sealing adds cost |

参考価格

- Ultrafine pure copper powder: $15-25 per kg

- Coarse pure copper powder: $10-15 per kg

- 大容量の場合は 40% の価格が安くなる可能性があります

Pricing depends on purity, particle size, production method, order quantity, packaging etc.

Pure Copper Powder Suppliers

Pure Copper Powder Suppliers

| 会社概要 | 所在地 |

|---|---|

| カイメラ・インターナショナル | アメリカ |

| GGP Metalpowder | ドイツ |

| アメリカン・ケメット・コーポレーション | アメリカ |

| 上海CNPC粉末材料 | 中国 |

| 三井金属 | 日本 |

| Nuclead | フランス |

サプライヤーの選択要素:

- Purity levels and grades offered

- 生産能力とリードタイム

- Average particle size ranges

- Customization of size distribution

- Packaging options and order quantities

- Pricing levels based on volume

- Compliance with international specifications

Pure Copper Powder Handling and Storage

Pure Copper Powder Handling

| 推薦 | 理由 |

|---|---|

| 適切な換気の確保 | 微粒子への曝露を防ぐ |

| 適切なPPEの使用 | 誤飲を避ける |

| 安全なプロトコルに従う | Reduce health hazards |

| 発火源を避ける | 可燃性粉塵の危険性 |

| Ground equipment | Prevent static discharge |

| 火花の出ない工具を使用する | 発火の可能性を防ぐ |

ストレージに関する推奨事項

- Store in stable containers in a cool, dry area

- Limit exposure to acids, ammonia, acetylene

- 温度を30℃以下に保つ

Proper precautions during handling and storage help preserve purity and prevent safety issues.

Pure Copper Powder Inspection and Testing

Pure Copper Powder Testing

| テスト | 詳細 |

|---|---|

| 化学分析 | ICP or XRF verifies composition |

| 粒度分布 | レーザー回折分析 |

| 見かけ密度 | ASTM B212に準拠したホール流量計テスト |

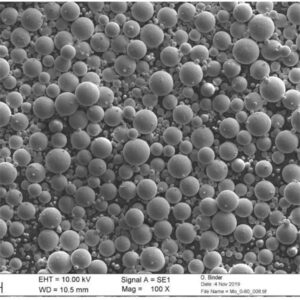

| 粉末形態 | 粒子形状のSEMイメージング |

| タップ密度テスト | メカニカル・タッピング後の密度測定 |

| 流量分析 | Gravity flow through a specified funnel |

Testing ensures the powder meets the required purity levels, particle characteristics, density specifications, morphology and flowability as per applicable standards.

Pure Copper Powder Pros and Cons

Advantages of Pure Copper Powder

- 優れた熱伝導性と電気伝導性

- Good corrosion resistance and bio-compatibility

- High purity provides optimal performance

- Easy to sinter and compress into high density components

- Ductile and malleable

- リサイクル可能で環境に優しい

Limitations of Pure Copper Powder

- Lower strength than many alloy powders

- 適度な高温耐酸化性

- Heavy compared to magnesium or aluminum

- Not suitable for high wear or load bearing applications

- Sensitive to contamination from zinc and sulfur

- Gradually tarnishes over time if uncoated

Comparison With Brass and Bronze Powders

Pure Copper vs. Brass and Bronze Powders

| パラメータ | 純銅 | Brass/Bronze |

|---|---|---|

| 密度 | 8.94 g/cc | 8.7-8.8 g/cc |

| 強さ | 220-340 MPa | 350~550MPa |

| 導電率 | 素晴らしい | グッド |

| 耐食性 | 素晴らしい | グッド |

| コスト | 低い | 中程度 |

| 用途 | Electrical, thermal | Hardware, decorative |

- Pure copper has higher conductivity and ductility

- Brass/bronze offer higher strength

- Pure copper better suited for thermal management

- Brass/bronze used for hardware and decorative items

Pure Copper Powder FAQs

Q: What are the main applications of pure copper powder?

A: Main applications include electrical contacts and brushes, welding rods, brazing alloys, diamond tools, heat sinks, net shape components made via powder metallurgy, friction materials, and conductive adhesives.

Q: What precautions should be taken when working with pure copper powder?

A: Recommended precautions include proper ventilation, appropriate PPE, safe handling protocols, grounding equipment, avoiding ignition sources, using non-sparking tools, and storing in stable inert containers away from contaminants.

Q: How does pure copper powder differ from electrolytic tough pitch (ETP) copper?

A: Pure copper powder has 99.5% or higher copper content, while ETP copper powder has minimum 99.5% copper. Pure copper provides slightly higher conductivity but the two are mostly interchangeable for common applications.

Q: What affects the properties of parts made from pure copper powder?

A: Key factors are apparent density, powder composition, particle size distribution, compaction pressure, sintering parameters, presence of impurities, and final part porosity.

Met3DPについて

製品カテゴリー

ホットセール

中国・青島に本社を置く積層造形ソリューションの大手プロバイダー。