Refractory Powder Materials represent a specialized class of inorganic non-metallic materials exhibiting extremely high heat resistance used across demanding industries. This comprehensive guide serves technical professionals and buyers understanding all key characteristics of refractory powders – spanning typical composition, critical properties data, manufacturing processes, applications, specifications and suppliers.

Overview of Refractory Powder Materials

Refractory powders comprise finely divided inert non-metallic materials demonstrating exceptional thermal stability, retaining strength and form at high temperatures exceeding 1000°C. Key subclasses include oxides, carbides, nitrides and ceramics.

Critical Attributes:

- Heat resistance over 1000°C

- Resist thermal shock

- Withstand corrosion

- 高融点

- Keep structural integrity

Their exceptional capabilities empower performance in furnaces, boilers, kilns, reactors and other extreme thermal environments where traditional materials fail rapidly.

典型的な構成

| 素材 | 役割 | Wt% レンジ |

|---|---|---|

| アルミナ | 熱特性 | 40-100% |

| Silica | Bind the matrix | 0-60% |

| Magnesia | Resist deterioration | 0-20% |

| Graphite | Increase thermal shock resistance | 0-15% |

Balancing key constituents enables optimizing characteristics like heat capacity, insulation, erosion resistance, melting point and cost.

Major Types of Refractory Powders

| タイプ | 説明 |

|---|---|

| Fused | Extreme purity, withstand over 1800°C |

| Sintered | Powder pressing/firing, lower cost |

| 炭化ケイ素 | Ceramic with high heat conductivity |

| Chromite | Resist slag, metal penetration |

| ジルコニア | 耐熱衝撃性 |

Refractory Powder Materials Manufacturing Processes

Producing advanced refractory powders requires stringent processing protocols under specialized conditions.

Primary Production Methods

| プロセス | 詳細 |

|---|---|

| Ball milling | メカニカルアロイング |

| ゾルゲル | 化学沈殿 |

| Fused | Molten phase quenching |

| 焼結 | Controlled powder consolidation |

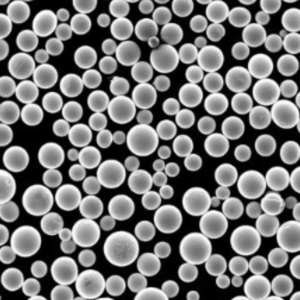

| プラズマスプレー | Very high temperature spheroidization |

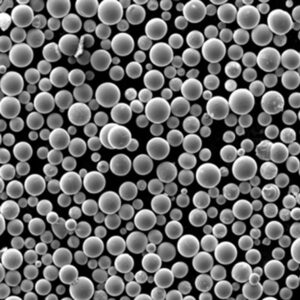

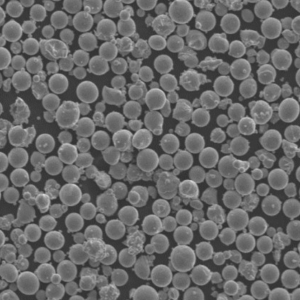

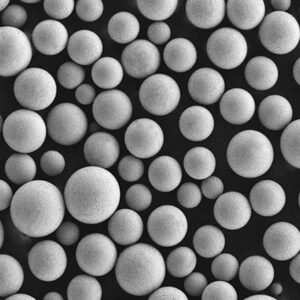

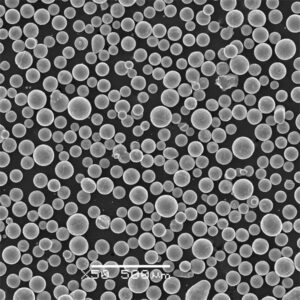

Resulting Particle Morphology

- 球形

- Angular

- Platelet

- Mixed globular and angular

Typical Refractory Powder Size Distribution

| メッシュサイズ | マイクロメーター |

|---|---|

| -170 | 90 μm |

| -325 | 45 μm |

| -500 | 25 μm |

Both standard and custom particle engineering allows tailoring product characteristics.

Properties of Refractory Powder Materials

| プロパティ | 代表値 |

|---|---|

| 融点 | Over 1600°C |

| 密度 | 2 - 6 g/cm3 |

| 圧縮強度 | 20 – 100 MPa |

| Flexural Strength | 10 – 60 MPa |

| 破壊靭性 | 2 – 10 MPa-m^1/2 |

| 熱伝導率 | 20 – 100 W/m-K |

| 電気抵抗率 | 10^8 – 10^13 Ohm-cm |

| Maximum Service Temperature | 1200°C – 2000°C |

Balancing requirements like melting point, heat capacity, thermal shock resistance, insulation value, chemical inertia and cost determines selection.

Applications of Refractory Powder Materials

Metallurgy and Foundries

- Crucibles, ladles

- Tundish nozzles

- Pouring shrouds

- Slag conditioners

高温処理

- Fired heater linings

- Ceramic kilns

- Incinerators

- Nuclear fuel cladding

化学工業

- Reformer tubes

- Reactor internals

- Syngas coolers

- Catalyst support structures

発電

- Boiler linings

- 熱交換器

- Steam pipes/valves

- Heat shields

Aerospace and Defense

- Missile casings

- Rocket nozzles

- Ablative composites

- Furnace elements

仕様とグレード

| 属性 | 代表値 |

|---|---|

| 純度 | Over 98% |

| 汚染 | Minimized S, P, Si, Fe |

| 粒子径 | 10μm – 150μm |

| Shape Factor | 0.8 – 1 |

| 比表面積 | 0.5 – 2 m2/g |

| Bulk Density | 0.6 – 2 g/cm3 |

| 流量特性 | Angle of Repose <40° |

Widely Used Refractory Grades

| グレード | 説明 |

|---|---|

| Tabular alumina | Platy powder, thermal shock resistance |

| Fused mullite | Alumina-silica, resists creep deformation |

| 炭化ケイ素 | Extreme hardness, thermal conductivity |

| Fused zirconia | Toughness, high ionic conductivity |

| Boron nitride | Outstanding dielectric properties |

Refractory Powder Materials Suppliers

| 会社概要 | 所在地 |

|---|---|

| Saint-Gobain | Global |

| RHI Magnesita | Brazil, Austria, China |

| Krosaki Harima | 日本 |

| Vesuvius | Europe, United States |

| Morgan Advanced Materials | United Kingdom, United States |

Pricing Estimates

| グレード | kgあたりの価格 |

|---|---|

| Tabular Alumina | $10-30 |

| 炭化ケイ素 | $50-150 |

| ジルコニア | $100-500 |

| その他 | $20-100 |

Economies of scale influence costs – customized compositions and strict quality requirements command premiums.

長所と短所

| 長所 | 短所 |

|---|---|

| Exceptional heat/corrosion resistance | Brittle mechanical properties |

| Ultra-high melting points | Sensitive processing methods |

| Withstand thermal shock | Higher material cost |

| Custom composition and properties | Limited form factors |

| Enable extreme environment applications | Challenging to fully characterize |

Pushing boundaries of thermal stability proves essential for continuous technology advancements – refractory powders make this possible despite production obstacles.

よくあるご質問

Q: What is the difference between refractory powders and refractory bricks?

A: Bricks are pre-formed consolidated constructions, while powders represent raw material feedstocks enabling fabrication of specialty refractory components through pressing/firing or advanced additive manufacturing methods.

Q: Can all refractory powders get 3D printed using AM technology?

A: Yes – binder jetting and directed energy deposition printing proves compatible with most thermally resistant alumina, zirconia and silicon carbide grades for previously impossible refractory geometries.

Q: Which refractory powder offers the highest service temperature?

A: Ultra-high purity fused mullite and zirconia grades reliably withstand over 2000°C for the most demanding furnace, aerospace and nuclear applications where alternatives melt or decompose.

Q: What is the difference between synthetic and natural refractory materials?

A: Natural raw materials like bauxite, magnesite and clay must get extensively processed into precisely controlled powders to achieve the enhanced uniformity and extreme thermal resistance possible with synthetic engineered formulations.

結論

This guide aimed providing a holistic reference on refractory powders – special materials overcoming limitations of ordinary metals and alloys in the hottest, most aggressive industrial environments through exceptional heat resistance. Please connect with an industry expert to discuss tailoring advanced refractory grades to your specific extreme processing needs. The possibilities stretch far.