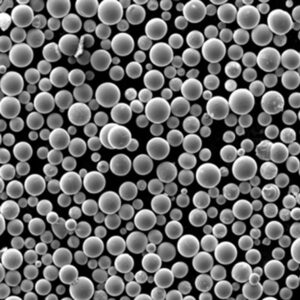

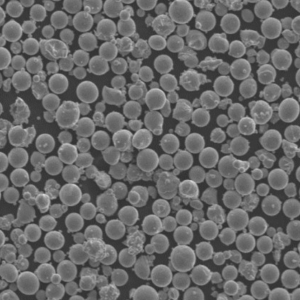

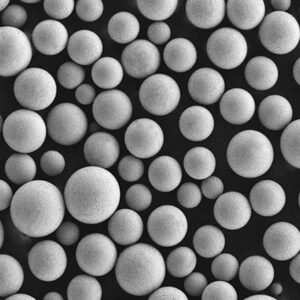

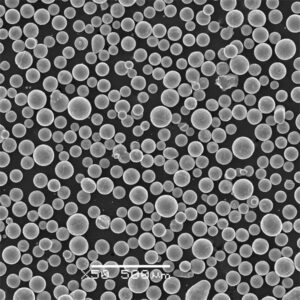

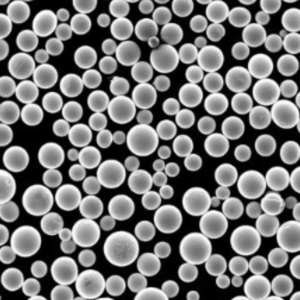

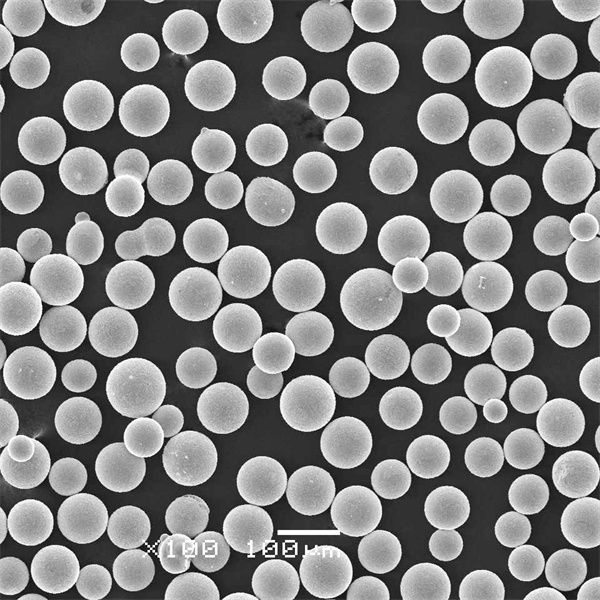

球状タングステン粉末 refers to fine granular particles consisting of pure tungsten metal shaped into highly round, smooth microspheres. Precision engineered spherical morphology allows these powders to deliver enhanced flowability, packing density, and sintered part quality compared to irregular crushed tungsten variants across manufacturing techniques leveraging tungsten’s unique density, strength, and thermal properties.

This guide covers different grades of spherical tungsten powders, production methods, key characteristics, specifications, pricing details from suppliers, pros and cons, and answers common questions on integrating spherical tungsten powder into components via advanced fabrication processes.

種類 球状タングステン粉末

There are several common spherical tungsten powder variants categorized by characteristics like purity, particle size, manufacturing method and density:

| タイプ | Typical Grades | 説明 |

|---|---|---|

| 純タングステン | 99.9%, 99.95%, 99.99% | No binders or stabilizers, just W metal |

| Alloyed Tungsten | W-Ni-Cu, W-Ni-Fe, W-Cu | Small percentages of nickel, copper, iron added |

| Size Classes | 1~10ミクロン 10~25ミクロン 25+ microns | Sub-micron nano scale also emerging |

| 密度 | 19.1-19.3 g/cc | Near theoretical density for tungsten |

Higher purity powders above 99.95% favored for specialty uses like radiation shielding, high temperature applications, or welding tips requiring strict chemistry.

生産方法

| 方法 | 説明 | Typical Outputs |

|---|---|---|

| プラズマ球状化 | Tungsten ingots atomized into droplets in a plasma torch then rapidly quenched | High purity, spherical morphology, moderate throughput |

| RF Plasma Sputtering | Tungsten vapor collects on substrates in a spherical morphology | Ultrafine nano-powders down to 20 nm sizes but low productivity |

| Thermal Plasma | Very high temp plasma jet melts tungsten rods into smooth molten droplets | Medium batch sizes with high density |

| 回転電極 | Centrifugal atomization forces shape droplets detached from spinning tungsten melt stream | Lower cost process but less control over size distribution |

Plasma methods allow precise tuning of particle formation leading powders with smoother, rounder profiles preferred for higher packing densities in sintering processes or binder flow dynamics across metal injection molding techniques.

の性質 球状タングステン粉末

Benefits stemming from the spherical morphology and purity include:

| プロパティ | 特徴 | メリット |

|---|---|---|

| Improved flowability | Powder feeds smoothly without clogging valves and pipes | Prevents jams during dispensing for printing processes |

| Enhanced packing density | Microspheres stack tightly with optimized space filling | Increases green compact density before sintering to near theoretical levels |

| Higher sintered density | Roundness aids internal pores and voids elimination | Maximizes mechanical performance – hardness, strength, thermal/electric conductivity |

| Consistent shrinkage | Low variation across precise batches | Tighter process controls and product performance standards |

| Increased surface area | Smoother micro-ball structure across larger collective area | Improves powders reactivity across chemical, electrical and thermal interfaces |

The premium qualities imparted by spherical morphology promote downstream fabrication innovations and tighter tolerances.

Applications of Spherical Tungsten Powder

Primary uses include:

| 産業 | 一般的なアプリケーション | メリット |

|---|---|---|

| アディティブ・マニュファクチャリング | Printed dense tungsten weights, shielding | High density without voids in printed geometry |

| 射出成形 | Radiation shielding, balancing components | Improved binder flow allows complex molds |

| エレクトロニクス | Heat sinks, electrodes, contacts | Enhanced thermal dissipation across larger surface area |

| Radiology Equipment | Collimator components, beam blocking shields | Dense high Z-number element blocks X-Rays |

| Vibration Dampening | Gyroscope weights, audio speaker mass balances | Density combined with ductility reduces resonance |

| Fishing Lure Weights | Eco-friendly non-toxic alternative to lead weights | Heavy weights for sinkers, jigs, or ballast |

Leveraging spherical morphology to fully harness tungsten’s intrinsically high density and temperature resistance supports innovative fabricated solutions across this wide range of industries.

仕様

| スタンダード | 代表値 | Definitions |

|---|---|---|

| ISO 5453 | 1-100 micron size<br>99.9% to 99.999% purity | International chemical assay and particle size conventions |

| ASTM B777 | 99.9%, 99.95%, 99.99% grades | Defines 3 purity grade types and sampling methodologies |

| MPIF 46 | -325 mesh powder, = 45 microns max | U.S. Metal Powder standard grade based on minimum sieve size |

Higher purity is generally favored but increases cost exponentially – balance against strictness of application requirements. Compare flow rates and apparent density between spherical vs irregular tungsten variants.

サプライヤーと価格

| サプライヤー | グレード | 価格見積もり |

|---|---|---|

| 中西部タングステン | 99.9% – 99.995% Purity<br>1-10 micron sizes | $50〜$150/kg |

| バッファロー・タングステン | 99-99.9% grades<br>Fine to coarse sizes | $45 – $280 per kg |

| Global Tungsten | 99.9%, 99.95%, 99.99%<br>カスタム合金 | $55 – $250 per kg |

| Nano Research Labs | 99.9% pure under 1 micron | $150+/kg |

Pricing ranges widely from $50/kg for common purity and size variants suitable for fishing lure weights and kinetics experiments requiring only basic density up to over $250/kg for high purity submicron nano powders used in specialized additive manufacturing or electronics applications where consistent chemistry and sizes are paramount.

長所と短所

| 長所 | 短所 |

|---|---|

| Enhanced flowability through binders and spraying mechanisms | Requires inert atmosphere handling given risks of hydrogen embrittlement from moisture |

| Higher green part density before sintering | Brittle after densification – requires ductile metal infiltrations |

| Improves surface finish of finished components | Handling as carcinogenic dust challenges at industrial levels |

| Environmentally friendlier than lead for heavy weights | Conflict sourcing concerns for raw tungsten supply chains |

| Allows ultrafine detail resolution with nano grade particles | Higher costs than crushing irregular powder from scrap |

Spherical shaping coupled with advanced manufacturing techniques expands applications for tungsten while mandatory handling precautions must be codified.

制限と考慮事項

Restrictions working with spherical tungsten powders:

- Maintain below 100 ppm oxygen/moisture prevents oxidation degradation

- Requires carbon or nickel alloy infiltration after densification to improve strength

- Brittle finished parts prone to crack propagation without reinforcement

- Binding mechanisms can be sensitivite to precise particle size distributions

- Preventing static buildup during handling mandatory as explosion risk

- Confirm supply chain sources and recycling protocols

- Note reduced shelf life to 2-3 years as higher surface area increases chemical activity

Proactively addressing these constraints enables securely scaling production across automotive, electronics and medical sectors where mitigating shortages of essential raw materials remains imperative.

よくあるご質問

| 質問 | 答え |

|---|---|

| What particle size is typically used? | 1-20 microns common, with nano grades below 1 micron gaining traction |

| What is the melting point of tungsten? | 3422 °C, one of the highest melting point metal elements |

| Is spherical powder safer than crushed variants? | Reduced dust is safer but still requires careful handling precautions |

| What is spherical tungsten mainly used for today? | Around 65% consumed for tungsten carbide production as precursor |

| How heavy is tungsten compared to steel? | Nearly 2X as dense. Steel ~8 g/cc, tungsten 19 g/cc |

| Where is natural tungsten ore mined? | China provides over 80% of current global supply |

| Does it carry conflict mineral risks like cobalt? | Less severe than cobalt but responsible sourcing still essential |

| Is the powder flammable or explosive? | No flammability but fine dust burn/detonation risks requiring precautions |

Broadening applications take advantage of premium qualities while securing supply chains against disruptions proves pivotal.

結論

Precision spherical shaping unlocks improved fabrication results across metal additive manufacturing and injection molding processes ready to displace waste-heavy traditional machining techniques across growing application segments as diverse as radiation shielding and audiophile speakers. But capturing these opportunities sustainably while navigating raw materials shortages layered atop geopolitical conflict concerns presses manufacturers toward responsible, localized supply chains increasingly prioritizing recycling. Simultaneously, innovations from augmented reality-guided handling procedures to reactive atmosphere glove boxes must permeate downstream to research and development labs as universities and startups expandaccess to capital equipment democratizing nanoscale explorations with high purity submicron spherical tungsten. By proactively developing staff expertise and codifying best practices embracing powder production hazards, manufacturers can responsibly develop this unique material’s potential.