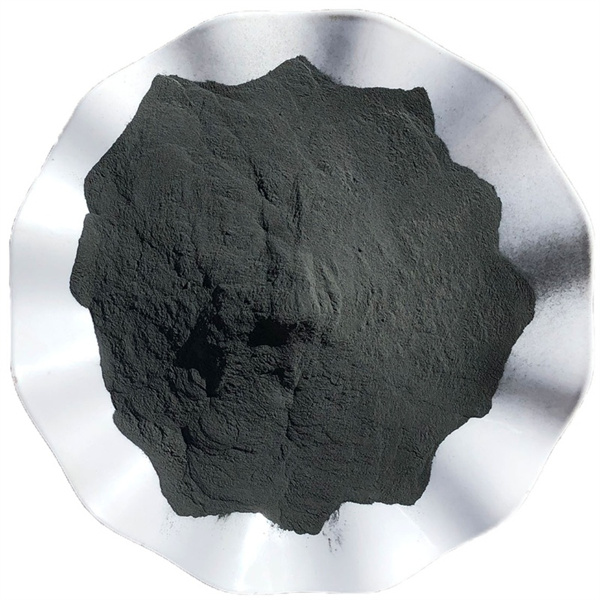

ステンレス鋼 316l 粉 is widely used across industries owing to its excellent corrosion resistance and mechanical properties. This guide provides an overview of 316L powder composition, attributes, processing, applications, and suppliers for additive manufacturing.

Introduction to Stainless Steel 316L Powder

Stainless steel 316L is an austenitic chromium-nickel stainless steel featuring:

表1: Overview of 316L stainless steel powder

| プロパティ | 詳細 |

|---|---|

| 密度 | 8.0 g/cm3 |

| 降伏強度 | 205 MPa |

| 引張強さ | 515 MPa |

| 伸び | 40% |

| 耐食性 | Resists pitting and acidic environments |

| 作業性 | Readily welded and fabricated |

These characteristics make 316L suitable for demanding applications from chemical processing equipment to medical implants. Powder bed fusion and directed energy deposition enable fabricating complex 316L parts.

化学組成

The composition of stainless steel 316l powder is:

表2: 316L stainless steel powder chemical composition

| エレメント | 重量 % | 役割 |

|---|---|---|

| 鉄(Fe) | バランス | Base metal |

| クロム(Cr) | 16-18% | 耐食性 |

| ニッケル(Ni) | 10-14% | 耐食性 |

| モリブデン (Mo) | 2-3% | 耐孔食性 |

| マンガン (Mn) | ≤ 2% | 脱酸素剤 |

| ケイ素 (Si) | ≤ 1% | 脱酸素剤 |

| リン (P) | ≤ 0.045% | Impurity limit |

| 硫黄(S) | ≤ 0.03% | Impurity limit |

| カーボン(C) | ≤ 0.03% | Impurity limit |

| 窒素(N) | ≤ 0.1% | Impurity limit |

The optimized composition of chromium, nickel and molybdenum boosts corrosion resistance. Let’s explore the properties next.

機械的特性

表3: stainless steel 316l powder properties

| プロパティ | 価値 |

|---|---|

| 密度 | 8.0 g/cm3 |

| 弾性率 | 193 GPa |

| 融点 | 1375°C |

| 熱伝導率 | 16.3 W/m-K |

| 電気抵抗率 | 0.074 μΩ-cm |

| 降伏強度 | 205 MPa |

| 引張強さ | 515 MPa |

| 伸び | ≧40% |

| 硬度 | 96 HB |

The combination of corrosion resistance, weldability, bio-compatibility, strength and ductility make 316L versatile for engineering across industries.

Production Process for ステンレス鋼 316l 粉

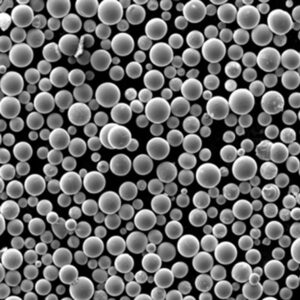

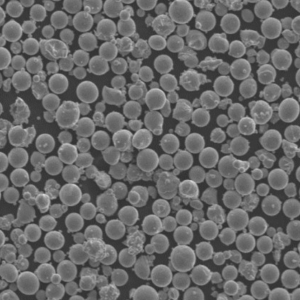

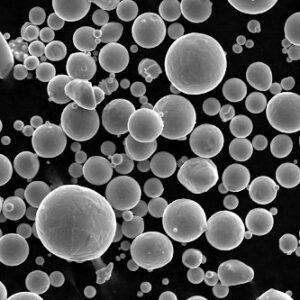

Common 316L powder production methods:

表4: 316L powder manufacturing processes

| 方法 | 説明 | 特徴 |

|---|---|---|

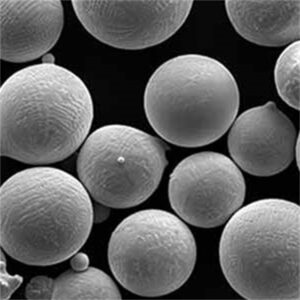

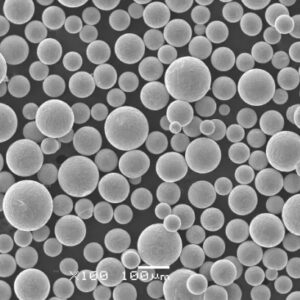

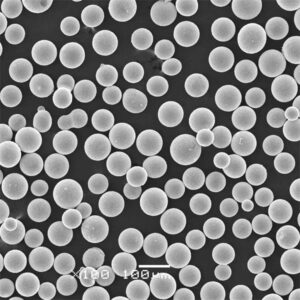

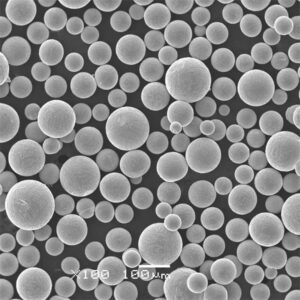

| ガス噴霧 | Molten metal stream atomized by inert gas jets | Spherical particles ideal for AM |

| 水の霧化 | Disintegration of molten stream by high pressure water | Irregular powder at lower cost |

| プラズマ霧化 | Electrode vaporization in water-cooled copper crucible by plasma | 制御された粒度分布 |

| 回転電極プロセス | Centrifugal disintegration of spinning molten metal by electric arcs | Tight particle distribution |

Gas atomization with auxiliary pulse laser technology allows tuning the stainless steel powder shape, size, surface chemistry and defects.

Applications of stainless steel 316l powder

Thanks to excellent fabrication properties combined with strength and corrosion resistance, common applications of 316L powder include:

表5: 316L powder applications

| 産業 | 申し込み | コンポーネント |

|---|---|---|

| 航空宇宙 | Structural brackets, hydraulic systems, engines | Air/spacecraft fuel tanks, valves, fittings, nozzles |

| 自動車 | Corrosive fluid handling systems | Fuel cells, pumps, valves, pipes |

| 建築 | Decorative/functional structures, signage | Railings, panels, letters |

| メディカル | インプラント、補綴物、器具 | Cranial plates, hip joints, surgical tools |

| 化学処理 | Tanks, vessels, valves | Mixers, reactors, heat exchangers |

| Food/beverage | Pipework, vessels, utensils | Mixing blades, conveyors, molds |

| マリン | Desalination, propulsion, environmental | Pumps, valves, heat exchangers |

3D printing enables relatively fast and affordable small batch production of end-use 316L parts. Let’s look at critical powder specifications next.

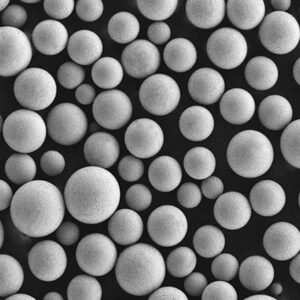

316L Powder Specifications for 3D Printing

表6: 316L powder specifications

| パラメータ | 仕様 |

|---|---|

| 粒子径 | 15-45ミクロン |

| 見かけ密度 | Typically > 4 g/cm3 |

| 流量 | Hall flowmeter > 15 s/50g |

| 形態学 | 球形 |

| フェーズ | オーステナイト系 |

| 不純物 | Low oxygen/nitrogen/sulfur |

| Manufacturing method | ガス噴霧 |

Careful powder production tailored to additive manufacturing achieves defect-free printing and mechanical performance surpassing cast and wrought 316L steel.

グローバルサプライヤー

Specialist manufacturers of 316L stainless steel powder include:

表7: 316L powder suppliers

| 会社概要 | 所在地 |

|---|---|

| サンドビック・オスプレイ | スウェーデン |

| LPWテクノロジー | イギリス |

| カーペンター添加剤 | 米国 |

| エラスティール | フランス |

| オベール&デュバル | フランス |

| プラクセア | 米国 |

These premium suppliers offer argon atomized 316L powder optimized for demanding additive manufacturing applications across industries.

ステンレス鋼 316l 粉 価格

表8: 316L powder cost considerations

| パラメータ | 詳細 |

|---|---|

| 数量 | Price per kg declines significantly above 100 kg |

| サイズ分布 | Tighter distributions more expensive |

| 純度 | Higher grades for AM can cost over 5x more than conventional 316L |

| Shape factors | Highly spherical powder costs more |

| 顧客サポート | Additional value-added services increase price |

In general, 316L powder ranges from $5/kg for conventional grades to $50/kg for specialized argon-atomized varieties with AM-optimized particle characteristics.

長所と短所

表9: 316L powder advantages vs disadvantages

| 長所 | 短所 |

|---|---|

| Resists corrosion and pitting | Less strong and harder than tool steels |

| Bio-compatible and non-magnetic | More difficult to post-process than aluminum alloys |

| Excellent ductility and weldability | Requires hot isostatic pressing for full density |

| Widely available | Surface roughness often necessitates post-processing |

| ニッケル合金より密度が低い | Limited large volume suppliers compared to wrought forms |

With appropriate design and printing parameters, 316L powder enables affordable fabrication of custom corrosion resistant parts across applications.

よくあるご質問

Q: Is 316L powder printable for additive manufacturing?

A: Yes, with optimized production methods for AM to control particle shape and defects, 316L prints very well across binder jetting, DED and PBF processes for low to mid volumes applications.

Q: What particle size is ideal for printing 316L powder?

A: An ideal 316L powder particle size distribution ranges from 15-45 microns, avoiding ultrafine or coarse fractions, to enable high packing density and limit porosity.

Q: What post-processing is recommended for as-printed 316L parts?

A: Stress relieving heat treatment, hot isostatic pressing, and surface finishing like media blasting, grinding or electropolishing help improve as-printed 316L microstructure and aesthetics.