ステンレス鋼粉末 enable complex geometry printing using additive techniques unmatched by conventional metal manufacturing. This guide covers alloy variants, particle specifications, properties data, pricing insights and comparisons to inform stainless powder procurement.

Introduction to Stainless Steel Powders

Key capabilities offered by stainless steel powders:

- Fabricate complex, lightweight components

- Achieve superior corrosion resistance

- Enable rapid prototyping and customization

Common alloys used include:

- 304L – Cost effective with excellent corrosion resistance

- 316L – Superb corrosion resistance with molybdenum addition

- 17-4PH – High strength, hardest stainless powder

This guide provides considerations when selecting stainless powders:

- Alloy Compositions and Production Methods

- Mechanical Properties Test Data

- Particle Size Distribution Recommendations

- Morphology, Flow Rate and Apparent Density

- Supplier Price Ranges Based on Volumes

- Corrosion Resistance Comparisons

- Pros vs Cons Relative to Solid Barstock

- FAQs on Printing Parameter Optimization

Stainless Steel Powder Compositions

表1 shows stainless steel powder alloy compositions by primary elemental additions with some variation across powder manufacturers:

| 合金 | Major Alloying Elements |

|---|---|

| 304L | Cr、Ni |

| 316L | Cr、Ni、Mo |

| 17-4PH | Cr、Ni、Cu |

Carbon is restricted (≤0.03%) in 304L and 316L to prevent carbide precipitation and maintain corrosion resistance and weldability.

Higher carbon in 17-4PH increases strength through martensitic hardening heat treatments.

Mechanical Properties and Test Methods

表2 shows typical minimum mechanical properties met by ステンレス鋼粉, with actual values varying based on build geometry, post-processing, and heat treatment selection:

| 合金 | 降伏強度 | 引張強度 | 試験方法 |

|---|---|---|---|

| 304L | 290 MPa | 540 MPa | ASTM E8 |

| 316L | 290 MPa | 540 MPa | ASTM E8 |

| 17-4PH | 1140 MPa | 1275 MPa | ASTM E8 |

Carefully review test data reports to ensure procured powder lots meet certification specs and application requirements prior to high volume purchasing commitments.

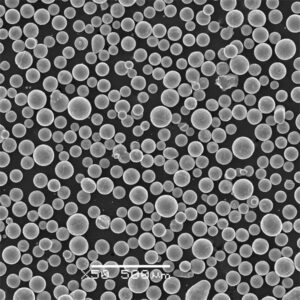

Stainless Steel Powder Particle Size Recommendations

表3 shows common particle size distribution categories used to classify stainless steel powders:

| サイズ範囲 | Typical Mesh | Common Printing Range |

|---|---|---|

| エクストラ・ファイン | -325メッシュ | 15-45ミクロン |

| ファイン | -230 +400 mesh | 32-63 micron |

| スタンダード | -170 +325 mesh | 44-105 micron |

Other key powder characteristics:

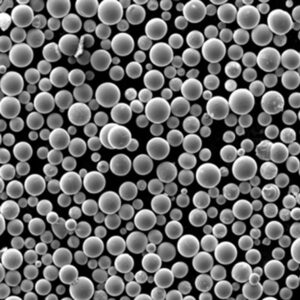

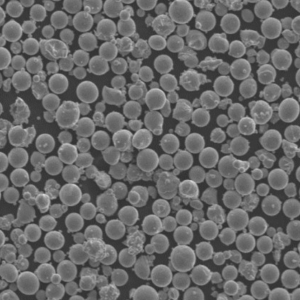

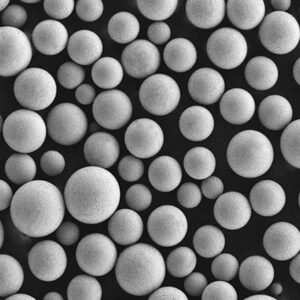

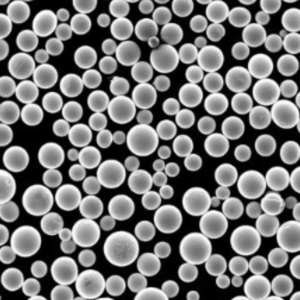

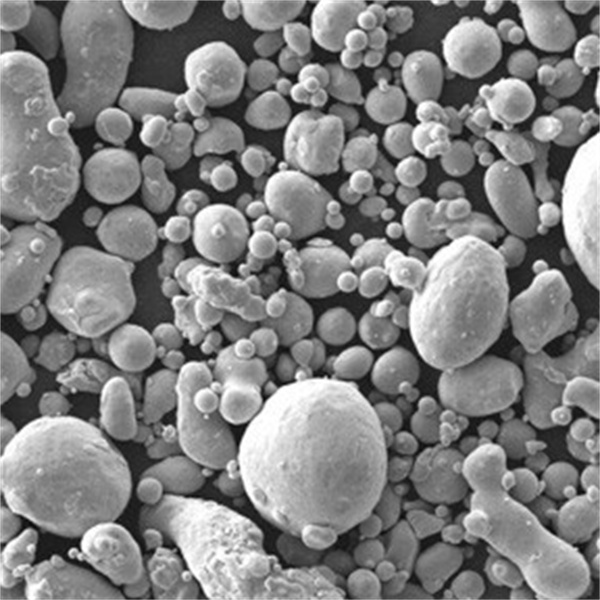

- 球状の形態

- Satellite free smooth surface

- Apparent density >90% of true density

- Hall flowmeter rates >30 seconds for 50 grams

For printing parameters, 25-45 micron mean size provides a robust starting point with good resolution and flowability.

Powder Morphology, Flow Rate and Density

表4 compares powder characteristics across general quality tiers that impact printing process stability:

| パラメータ | Premium Powder | Entry-level Powder |

|---|---|---|

| 形態学 | 球形度が高い | Jagged, irregular shapes |

| 流量 | Hall flow > 30s for 50g | Hall flow < 25s for 50g |

| 見かけ密度 | > 90% true density | Often <80% true density |

| 含水率 | <0.01% | >0.02% |

Poor powder flow and density require extra parameter adjustments to achieve print quality, affecting productivity. Request hall flow seconds and density data from suppliers.

Stainless Steel Powder Pricing

表5 outlines rough pricing estimates for common ステンレス鋼粉 under normal market conditions:

| 注文量 | 価格見積もり |

|---|---|

| 10キロ | $100+/kg |

| 100キロ | $50+/kg |

| 500+ kg | $30+/kg |

| 1000キロ以上 | Subkey discounts |

- Bulk discounts beyond 500-1000 kg

- Actual prices fluctuate relative to raw material costs

- Carefully review true yields vs “good” powder

- Low prices often indicate poor consistency

Compare price lists but focus evaluations on test data quality to identify best value propositions aligning with print process capabilities.

Stainless Steel Powder Corrosion Resistance

表6 compares corrosion resistance across common alloys:

| 合金 | Typical Environments |

|---|---|

| 304L | Good general chemical resistance suitable for mild corrosive conditions |

| 316L | Excellent corrosion performance for harsh environments with chlorides and acids |

| 17-4PH | Moderate corrosion resistance with lower chromium, nickel content |

Molybdenum enhances pitting and crevice corrosion resistance in 316L powder. Higher chromium also boosts passivity.

Carefully select alloys optimized for intended operating environments based on chemicals, concentration, pH and temperatures expected during service life.

Pros vs Cons: Powder vs Solid Barstock

表7

| メリット | デメリット | |

|---|---|---|

| ステンレススチール・パウダー | 複雑な形状 | より高いコスト |

| Great corrosion resistance properties | 後処理 | |

| 軽量化 | Print parameter optimization | |

| Stainless Steel Solid Bar | Cost effective | Shape limits |

| 空室状況 | Much heavier | |

| 加工性 | 材料廃棄物 |

In general, stainless steel powder justifies higher prices for low volume complex components where corrosion resistance and weight reduction are vital. Bar forms offer affordability for simple shapes in high production use cases.

よくあるご質問

Table 8 – Common questions:

| よくあるご質問 | 答え |

|---|---|

| Should I review test reports? | Yes, scrutinize powder certification data thoroughly |

| What size powder particles should I start with? | 25-45 micron for robust printing |

| What factors impact consistency? | Raw powder production technique affects variability |

| How much powder should I buy initially? | Start small scale to validate print process |

Table 9 – Application-focused advice:

| よくあるご質問 | 答え |

|---|---|

| How should I adjust parameters for printing food-grade stainless equipment? | Optimize for low surface roughness and eliminate crevices |

| What post-processing can reduce porosity for marine parts? | Consider hot isostatic pressing to maximize corrosion resistance |

| Which alloy maximizes yield strength for load-bearing components? | 17-4PH precipitation-hardened stainless |

| What stainless powder is optimal for high-temperature furnace parts? | 316L powder offers excellent oxidation resistance |