超合金金属粉 enable additive manufacturing of high strength, heat resistant alloy components unmatched by conventional metals. This guide covers superalloy compositions, powder specifications, properties data, pricing insights and comparisons to inform powder metallurgy procurement decisions.

Introduction to superalloys metal powder

Key capabilities of superalloy powders:

- Withstand extreme temperatures up to 85% of melting points

- Retain strength, corrosion resistance and stability in harsh environments

- Facilitate innovative complex part geometries through AM

Common classification groups:

- Nickel-based – Inconel, Waspaloy, Rene alloys

- Cobalt-based – Haynes, HS alloys

- Iron-based – A286, 901, 304 variants

This guide provides considerations when selecting superalloy powder:

- Alloy Compositions and Powder Production Methods

- Mechanical Properties, Test Methods and Data Sheets

- Particle Size Distribution Specifications

- Powder Morphology Characteristics and Consistency

- Pricing Models Based on Order Volumes

- Oxidation and Corrosion Resistance

- Pros vs Cons: Powder vs Solid Bar

- FAQs on Quality Control and Applications

Let us explore superalloy powders specifically…

超合金金属粉 作曲

表1 shows nominal compositions of common nickel and cobalt-based superalloys with some variation between powder manufacturers.

| 合金 | 主要合金元素 |

|---|---|

| インコネル718 | Ni, Fe, Nb, Mo, Al |

| インコネル625 | Ni、Cr、Mo、Nb |

| Rene 41 | Ni, Co, Cr, Mo, Ti, Al |

| ワスパロイ | Ni, Co, Cr, Mo, Ti, Al |

| ヘインズ 282 | Co, Cr, W, Mo, Ti, Al |

Small additions of boron, carbon, zirconium and silicon also tailor grain structure, strengthen boundaries and enhance high temperature behavior through precipitate formation.

Mechanical Properties and Test Methods

表2 shows typical minimum mechanical properties met by common superalloy powders, with actual values varying based on build geometry, post-processing, and heat treatment.

| 合金 | 降伏強度 | 引張強度 | 試験方法 |

|---|---|---|---|

| インコネル718 | 1035 MPa | 1275 MPa | ASTM E8 |

| Rene 41 | 760 MPa | 1035 MPa | ASTM E8 |

| ヘインズ 282 | 830 MPa | 1035 MPa | ASTM E8 |

Review test reports carefully to ensure powder lots procured meet certification requirements and application needs.

superalloys metal powder Particle Size Specs

表3 shows particle size distribution categories generally used to classify superalloy powders:

| サイズ範囲 | Typical Mesh |

|---|---|

| サブミクロン | -100 +325 mesh |

| ファイン | -140 +325 mesh |

| エクストラ・ファイン | -200 +325 mesh |

Other key particle characteristics:

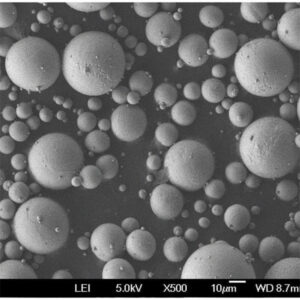

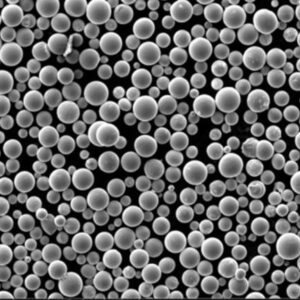

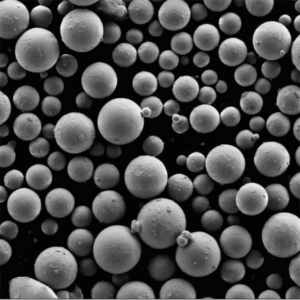

- 球状の形態

- Satellite free smooth surfaces

- Controlled size distribution

- Flow rates >30s in Hall funnel

For printing, 25-45 micron mean sizes give a good balance of resolution and flowability. Adjust based on specific machine capabilities and minimum feature sizes needed.

超合金金属粉 価格

表4 provides rough superalloy powder price estimates under typical market conditions:

| 注文数量 | 価格見積もり |

|---|---|

| 10キロ | $450+/kg |

| 100キロ | $275+/kg |

| 500 kg | $225+/kg |

| 1000キロ以上 | Subkey discounts |

- Special alloys command premium baseline pricing

- Large orders in 500-1000+ kg range enable >50% discounts from list price points through bulk buying leverage

- Actual market prices tied to raw material input price fluctuations

Oxidation and Corrosion Resistance

Superalloys maintain exceptional stability even when exposed to extreme environments:

表5

| 合金 | Typical Service Temp. | 耐食性 |

|---|---|---|

| インコネル718 | 700°C | 素晴らしい |

| Rene 41 | 760°C | 素晴らしい |

| ヘインズ 282 | 1095°C | 素晴らしい |

Carefully engineered compositions with nickel, chromium and aluminum form tenacious passivating oxide barriers protecting surfaces against attack up to very high proportions of melting points.

Elements like molybdenum further boost pitting and crevice corrosion resistance.

Pros vs Cons: Powder vs Solid Bar

表6

| メリット | デメリット | |

|---|---|---|

| Superalloy Metal Powder | 複雑な形状 | より高いコスト |

| Superior properties | 後処理 | |

| 軽量化 | Parameter optimization | |

| Superalloy Solid Bar | 低コスト | Shape limits |

| 空室状況 | Much heavier | |

| 加工性 | 材料廃棄物 |

In general, superalloy powder justifies premiums for low volume complex components where advanced properties are vital. Standard mill forms offer affordability for simple shapes in high production use cases.

よくあるご質問

表7 – Common questions:

| よくあるご質問 | 答え |

|---|---|

| Should I review test reports? | Yes, scrutinize all certs thoroughly to ensure powder quality |

| What size powder particles should I start with? | 25-45u provides a robust starting point |

| What factors affect consistency? | Raw powder production method impacts variability |

| How much powder should I buy initially? | Start small scale to validate print process control |

Table 8 – Application-specific advice:

| よくあるご質問 | 答え |

|---|---|

| What post processing should I use for hot section turbine blades? | Hot Isostatic Pressing to remove pores and enhance fatigue performance |

| What alloy maximizes high temperature yield strength? | Consider Rene 41 or Haynes 282 alloys |

| How can I minimize part anisotropy effects? | Utilize elevated temperature heat treatments to relieve stresses |

| What’s better for cryogenic parts – powder or cast? | Powder enables complex conformal channels unlike castings |