概要 Tantalum Powder Supplier

tantalum powder supplier refers to fine particles of tantalum metal used across electronics, chemicals, metals manufacturing, medical implants, and aerospace industries. Key properties like high melting point, density, electrical conductivity, and corrosion resistance expand its applications for high-performance products.

With strong market demand and complex supply chains, choosing a reputable tantalum powder supplier with efficient sourcing, stringent quality control and reliable delivery is essential.

This guide covers capabilities of major global tantalum powder manufacturers, typical specifications, production methods, pricing trends, comparisons, and recommendations for selecting suppliers.

Top 5 tantalum powder supplier Manufacturers

Tantalum powder production is concentrated across a few specialist metal processors with mining sources and refining capacity spanning different continents.

Here are top tantalum powder suppliers globally:

| 会社概要 | HQ | Facilities | 材料 |

|---|---|---|---|

| H.C.スタルク・ソリューションズ | ドイツ | Germany, US, Thailand, China | Ta, Nb, Re powders |

| Global Advanced Metals | アメリカ | アメリカ | Ta ingot, powders |

| JX Nippon | 日本 | 日本 | Ta, Nb specialty metals |

| Ultramet | アメリカ | アメリカ | Ta, W heavy metal powders |

| Xi’an Tuoxu | 中国 | 中国 | Ta powder and paste |

These industry leaders offer the complete range of standard and customized tantalum powders tailored across purity levels, particle characteristics, shaping, alloy grades etc. serving diverse commercial and defense applications globally.

Key タンタル粉末サプライヤー 特徴

Tantalum powders exhibits unique properties that provide advantages, and are available under various specification grades and powder characteristics:

プロパティ

| 特徴 | 代表値 | 意義 |

|---|---|---|

| 融点 | 2996 °C | Retains strength at high temps |

| 密度 | 16.6g/cm3 | Used for ballasting, weighting |

| ヤング率 | 186 GPa | Stiffness and elasticity |

| 電気抵抗率 | 13-16 μΩ-cm | Stable operating temps for electronics |

| 熱伝導率 | 57 W/m.K | Heat dissipation for thermal management |

| 熱膨張 | 6.5 x 10-6/K | Dimensions stability with temperature |

粉体仕様

| パラメータ | レンジ |

|---|---|

| 純度 | 99.9% to 99.995% |

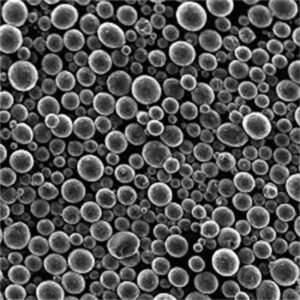

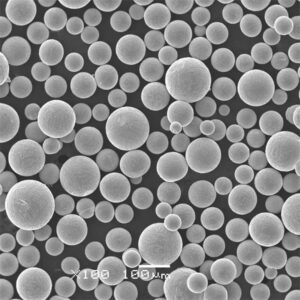

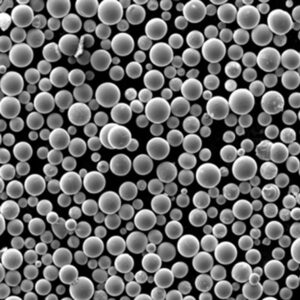

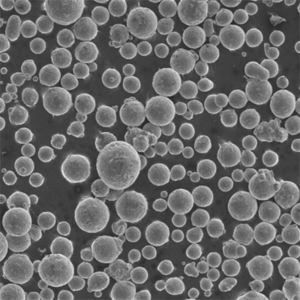

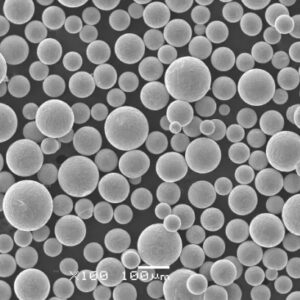

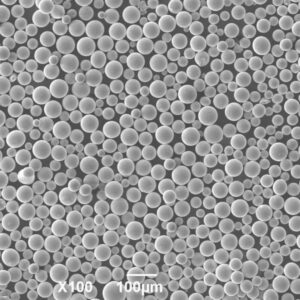

| 粒子径 | 1 to 250 Microns |

| 見かけ密度 | 3 – 10 g/cc |

| タップ密度 | 5 – 12 g/cc |

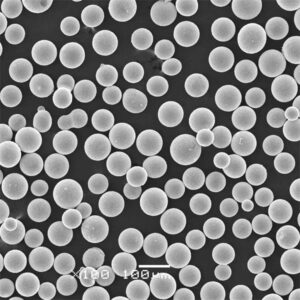

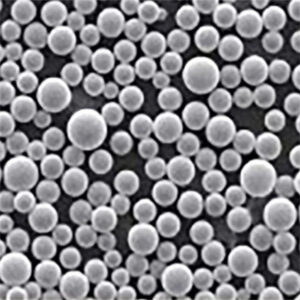

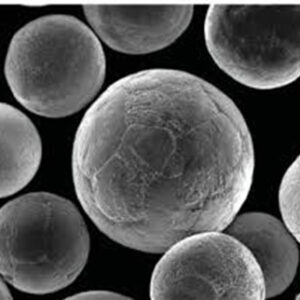

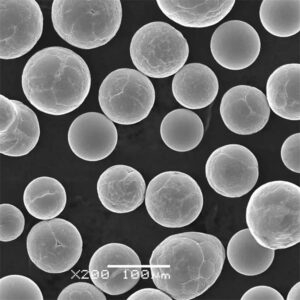

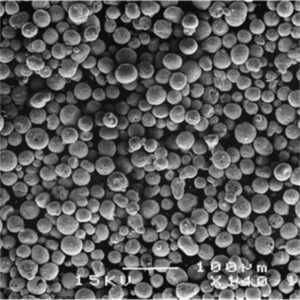

| 形 | 不規則、球形 |

| Alloy Option | Pure Ta, TaW |

These characteristics enable tantalum use across miniaturized capacitors, medical implants, aerospace engines, and chemical reactors in corrosive environments.

Tantalum Powder Manufacturing Process

Tantalum powder is produced through metallic sodium reduction where tantalum pentoxide is reduced with pure sodium.

Key Steps

- Refining of tantalite ore concentrate containing Ta, Sn, Fe

- Chemical separation and purification via solvent extraction

- Reduction with sodium yields tantalum powder

- Further crushing, milling and shaping based on particle requirements

- Controlled conditions prevent contamination for electronics

Manufacturers continually enhance processes as demand increases for finer spherical powders allowing greater quality consistency.

グレードと仕様

Tantalum powder for commercial uses is available under different specification grades suitable for various applications:

Electronics-grade high purity fine powder*

| パラメータ | レンジ |

|---|---|

| 純度 | > 99.95% |

| 酸素 | < 1000 ppm未満 |

| Chloride | < 50 ppm |

| サイズ | < 150 μm |

| CV/g | 15,000 to 40,000 μFV/g |

Low impurity levels demanded for capacitors

工業用 standard powder

| パラメータ | レンジ |

|---|---|

| 純度 | 99.9% to 99.5% |

| サイズ | 1 to 250 μm |

| 見かけ密度 | 最大 50% の真密度 |

| Shapes | 不規則、球形 |

These cover requirements across metallurgy as alloying addition, mill product fabrication, thermal spray coatings, medical implants etc. Custom particle dimensions, size distribution fraction yields, apparent/tap density ratios, extent of spheroidization and special handling to control contamination levels per application needs are possible.

Pricing for Tantalum Powder

As a high performance specialty metal with complex extraction, Boston-based research firm Argus Metals provides indicative pricing for Ta powder on a monthly basis.

Some typical price ranges:

| 素材 | 純度 | kgあたりの価格 |

|---|---|---|

| タンタル粉末 | 99.9% | $450 – $600 |

| タンタル粉末 | 99.95% | $650 – $950 |

| タンタル粉末 | 99.997% | $1300 – $2000 |

- Prices rose sharply from $100 levels in early 2000s to peak around $750/kg before moderating

- Electronics and capacitor demand surges alternating with periods of oversupply affect prices

- Very high purity grades for capacitors demand substantial premiums

Sourcing from regions with lower labor, regulatory, energy and transport costs provide some cost benefit for buyers.

Pros and Cons of Tantalum Powder

Here is a comparative look at some of the advantages and disadvantages of tantalum powder:

メリット

- Extremely heat resistant retaining strength over 3000°C

- Highest capacitance per volume ideal for electronics

- Bioinert making it suited for medical implants

- Alloys readily with niobium, tungsten or rhenium

- Easily fabricated into wire, rod or sheet via sintering

- Can be thermally sprayed for local corrosion protection

デメリット

- Relatively expensive compared to steels or titanium

- Low ductility and fracture toughness limits forming flexibility

- Requires high temperatures or aggressive acids for processing

- Controlling impurities critical for high reliability use

- Susceptible to embrittlement if contaminated during manufacture

For niche applications, tantalum delivers differentiated performance offsetting higher base material costs.

Tantalum Powder vs Tantalum Metal

Both tantalum powder and tantalum wrought products like rod, wire or plate provide specific advantages in manufacturing and properties:

Key Differences

| パラメータ | タンタル粉末 | Tantalum Wrought |

|---|---|---|

| 製造方法 | Sodium reduction | Ingot metallurgy |

| コスト | より低い | より高い |

| 加工 | プレスと焼結 | Forging, rolling |

| プロパティ | Isotropic, moderate toughness | Anisotropic, higher toughness |

| アプリケーション | MIM, thermal spray coatings | Sheets, fasteners, surgical implements |

- Capability to press and sinter near net shape parts from Ta powder offsets lower raw material efficiency

- Customized powder morphology and lack of primary melting suits niche component needs

Industrial Uses of Tantalum Powder

With its unique properties, tantalum powder is a critical material across several industrial sectors:

エレクトロニクス – High reliability capacitors, wave guides, electron emitters

Aeronautics – Jet engine components like combustor liner hooks, fasteners

ケミカル – Corrosion resistant reactors, heat exchangers, valves メディカル – Joint replacements, dental implants, screws

光学 – Sputtered thin films for reflective coatings on lenses and mirrors

Developments in powder manufacturing enable increased adoption. For instance, conformal printing applying a polymer binder on powder layers allows complex tantalum circuit structure fabrication suited for demanding miniaturized electronics in satellites, missiles etc.

Choosing a Reliable Tantalum Powder Supplier

With tantalum playing an important role across several advanced technologies, selecting a capable and stable powder supplier is vital for buyers.

Here are key considerations when evaluating tantalum powder manufacturers:

Technical Factors

- Stringent process controls and in-house testing to ensure tight chemistry tolerances avoiding critical contaminants

- Capability to customize particle size distribution yields within ideal fractions per application

- Ability to shape powder and spheroidize irregular morphologies for enhanced powder flow and packing

- Conformance to ASTM standard metrology practices for measurement and characterization

- Data transparency including lot variability in chemical assays and particle analysis

Commercial Factors

- Long term security of sources and supply chain logistics reducing vulnerability to potential market tightness

- Reasonable minimum order quantity, inventory turns ratio and lead times for flexibility

- Willingness to produce special sizes or alloy variations in lower volumes

- Responsiveness to requests for samples, trials, prototyping ahead of full production commitments

- Competitive transparent pricing with discounts for higher purchase quantities and long term programs

These best practices ensure buyers receive molybdenum powder optimal for their manufacturing process and reliable on-time deliveries to avoid business disruption.

よくあるご質問

Q: Which tantalum powder grade is preferred for medical implants?

A: High purity spherical powder above 99.95% purity level ensures surgical grade biocompatibility, corrosion resistance and optimal processability for fabricating bone screws or plates via metal injection molding tantalum parts.

Q: What analysis helps determine fitness specifications of tantalum powder for electronics applications?

A: Besides chemistry purity verified by GDMS, ICP or XRF testing, nitrogen and oxygen composition indicates levels of nitride or oxide contamination. Sieving per ASTM B822 confirms cumulative particle undersize distribution against micron thresholds while microscopy verifies powder morphology..

Q: What are critical quality checks conducted on tantalum powder at supplier facilities?

A: Visual inspection under high magnification for satellite levels and morphology, monitoring powder flow rate through a hall flowmeter funnel, bulk and tapped density ratios to optimize packing efficiency, pressing test samples and checking green density, chloride analysis using ion meters, and monitoring effect of test sintering cycle on shrinkage, density and mechanicals.

Q: What are the documentation provided along with tantalum powder shipments?

A: Quality conformance certificates affirming chemical composition and physical characteristics testing data for production lots evidence materials pedigree. Safety data sheets support safe handling while export/import paperwork streamline customs clearance reducing delays.

Q: Why is surface area an important metric for tantalum powders used in polymerization catalysts?

A higher surface area to mass ratio improves contact efficiency and interaction levels when used as a precursor compound enhancing process performance metrics like polymer grade yields, reaction time and operating temperatures for the production scale reactor.

結論

In summary, tantalum powder offers differentiated performance in electronics, alloying, chemical reactors and medical implants owing to exceptional corrosion resistance, thermal stability, elevated melting point, and bioinertness.

Decades long expertise makes leading international suppliers like H.C. Starck and Global Advanced Metals reliable partners offering high purity tantalum powder with precise particle engineering, stringent process controls, and extensive customization options suited for client manufacturing methodology.

Careful verification of assay certificates, evidence of production quality rigor, supply chain security, commercial flexibility, and technical customer support during preliminary product trials and qualification processes validate vendor dependability essential for smooth operations.

With both market outlook and downstream demand expanding for advanced technologies, establishing long term supply programs with capable tantalum powder manufacturers guarantees buyers the specialty material access and consistency vital for product quality and business growth.