Titanium alloy powders contain titanium as the main element combined with other metals like aluminum, vanadium or iron. The alloy composition imparts enhanced properties for uses across aerospace, medical devices and more.

Types of Titanium Alloy Powders

Common titanium alloy formulations in powder form:

| 合金 | Tiコンテンツ | その他の要素 | 主要物件 |

|---|---|---|---|

| Ti-6Al-4V | 90% | 6% Al, 4% V | 高強度、低密度 |

| Ti-6Al-7Nb | 90% | 6% Al, 7% Nb | 生体適合性、耐食性 |

| Ti-10V-2Fe-3Al | 82% | 10% V, 2% Fe, 3% Al | Heat resistance, hardened |

| Ti-3Al-2.5V | 93% | 3% Al, 2.5% V | Elevated temperature strength |

- Titanium alloyed with aluminum, vanadium, iron and niobium balance hardness, strength and density

- Specific elements tune mechanical, physical and biological properties for target applications

- Mixtures optimize high temperature behavior, wear performance, weldability etc.

- Aluminum stabilizes titanium crystal structure for workability; vanadium enhances strength

So tailored combinations of metals in titanium alloys achieve application-specific functional properties.

Titanium Alloy Powder Production

Common techniques to produce titanium alloy powders:

| 方法 | プロセス | 説明 | Particle Properties |

|---|---|---|---|

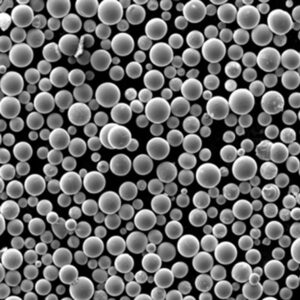

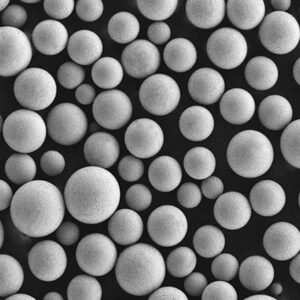

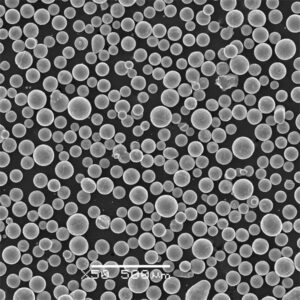

| ガス噴霧 | Molten stream impinges on gas jets | Rapid cooling forms spherical particles | 優れた流動性 |

| プラズマ霧化 | Higher temperature plasma melts alloys | Very fine spherical powder production | Sub-micron sizes |

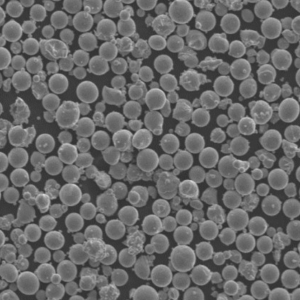

| ヒドリド脱水素 | Hydride phase comminution | Irregular brittle particles from hydrides | Moderate flow |

| メカニカルアロイング | Powder particles deformation welded | Composite structure with fine grain size | Poor flow |

- Gas and plasma atomization generate fine spherical alloy powders suitable for additive manufacturing

- Hydride-dehydride method crushes brittle hydride phase into small particles

- Mechanical alloying welds smaller particles into composite aggregates through deformation

So various techniques allow tailored titanium alloy particle sizes, shapes and internal microstructures.

の応用 チタン合金粉末

Titanium alloy powders enable high performance parts across sectors:

| セクター | 申し込み | Properties Utilized |

|---|---|---|

| 航空宇宙 | Turbine blades, airframe parts | High specific strength |

| インダストリアル | 食品加工機器 | 耐食性 |

| 自動車 | Connecting rods, valves | 耐熱性 |

| バイオメディカル | インプラント、補綴 | 生体適合性 |

| ディフェンス | Armor materials | Ballistics protection |

| 積層造形 | 3D printed parts | 印刷適性 |

- Lightweight strength allows fuel savings in aircraft and vehicles with titanium components

- Bio-neutral titanium alloy implants avoid rejecting by the human body

- Corrosion resistance suits aggressive chemicals in industrial plants

- Alloy tailoring creates customer titanium grades for each application

So tailored titanium alloy powders enable advanced manufacturing across diverse demanding industries.

Specifying Titanium Alloy Powder

Key titanium alloy powder quality metrics:

| パラメータ | 代表値 | Testing Method |

|---|---|---|

| 合金組成 | Element percentage by weight | ICP分光法 |

| 粒度分布 | Range and average size | レーザー回折 |

| 見かけ密度 | Up to 85% of true density | スコット・ボリュメーター |

| タップ密度 | Up to 95% of true density | Measured by tapping |

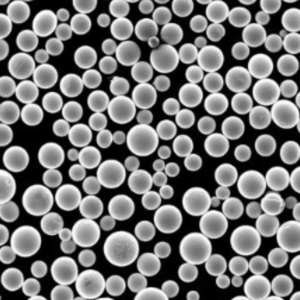

| 粒子形状 | Sphericity, smoothness | SEMイメージング |

| 粉体流量 | Angle of repose, Hall flowmeter | Standard test funnels/containers |

- Composition checks confirm percentages of titanium, aluminum, vanadium etc.

- Particle size distribution ensures suitability for intended manufacturing process

- Density indicates packing efficiency and porosity

- Particle shape affects application performance and powder handling

- Flow rates qualify suitability for automated transport and metering

So these metrics help ensure the purchased titanium alloy powder meets application requirements.

Comparing Titanium Alloy Powder Types

How do some titanium alloys measure up?

| 合金 | Ti-6Al-4V | Ti-6Al-7Nb | Ti-10V-2Fe-3Al |

|---|---|---|---|

| 密度 | 4.43 g/cc | 4.52 g/cc | 4.38 g/cc |

| 引張強さ | 128 ksi | 126 ksi | 115 ksi |

| ヤング率 | 16 msi | 10 msi | 15 msi |

| 最高使用温度 | 700°F | 750°F | 800°F |

| 生体適合性 | 中程度 | 素晴らしい | 貧しい |

| コスト | 低い | 高い | 中程度 |

- Ti-6Al-4V is the workhorse titanium alloy combining performance and cost

- Nb and Ta alloys offer superior biocompatibility for medical uses

- Higher vanadium and Fe enable stability at elevated temperatures

- Aluminum containing alloys have higher strength-to-weight ratio

So each titanium alloy formulation has specific advantageous properties for target applications.

Suppliers of Titanium Alloy Powder

Leading global producers of titanium alloy powders:

| 会社概要 | 本社所在地 | グレード | 生産能力 |

|---|---|---|---|

| ATI粉末冶金 | 米国 | Ti-6Al-4V, custom alloys | 5,000 metric tonnes/year |

| テクナ | カナダ | Ti-6Al-4V and others | Not published |

| Hoganas Group | スウェーデン | Ti-6Al-4V | 3,000 metric tonnes/year |

| TLSテクニーク | ドイツ | TiAl, TiAlNb, Ti powders | Not published |

| CNPC パウダー | 中国 | Ti-6Al-4V, TiAl | 10,000 metric tonnes/year |

- USA’s ATI Powder Metals is a leading producer of titanium alloy powders globally

- Sweden’s Hoganas Group also operates significant titanium powder manufacturing

- China hosts several large titanium alloy powder makers seeking global exports

- Smaller players also participate in the growing titanium powder industry

So supply capacity continues scaling up to meet expanding demand for titanium alloys.

チタン合金粉末 価格

Ballpark titanium alloy powder prices:

| 合金 | Pricing per kg | 粒子径範囲 |

|---|---|---|

| Ti-6Al-4V | $50 – $150 | 15 to 120 microns |

| Ti-6Al-7Nb | $250 – $500 | 5 to 45 microns |

| Ti-10V-2Fe-3Al | $75 – $200 | 15 to 63 microns |

| Ti-3Al-2.5V | $100 – $150 | 45 to 150 microns |

- Prices depend heavily on buy volumes and particle size distribution specifics

- Specialized alloys and fine medical grades fetch higher pricing

- Ti-6Al-4V is most economically produced at industrial scales

- Contracts over 5-10 tonnes receive discounted rates

So titanium alloy powder remains relatively expensive, limiting applications primarily to aerospace and defense sectors.

Titanium Alloy Powders FAQs

| 質問 | 答え |

|---|---|

| What colors can titanium alloys be? | Natural gray is most common. Colorizing surface treatments also applied. |

| Do the powders require special handling? | Inert gas blanketing advisable to prevent oxidation while handling. |

| Is cold spraying possible with these powders? | Yes, particle deformation enables high adhesion coatings. |

| Are titanium alloys non-magnetic? | Yes, all grades have very low magnetic permeability. |

| Can these powders be safely shipped by air? | Yes, no transport restrictions except for very fine reactive powders. |

So titanium alloy powders lend themselves well to most metal powder handling, processing and coating operations.

結論

In summary, titanium alloy powder provides the design flexibility to balance density, strength, modulus and biocompatibility for advanced engineering requirements across industries. Manufacturing techniques impart tailored particle characteristics. Alloy formulation allows custom property tuning. Despite relatively high prices over $50/kg, titanium alloy powder brings greater performance in defense, medical, aerospace and automotive applications where component performance overrides cost considerations.