チタンモリブデン合金粉 enhance high-temperature strength and creep resistance for lightweight aerospace designs. This guide reviews TiMo alloy powder compositions, key characteristics, production methods, suitable applications, specifications, purchasing considerations, supplier comparisons, and pros/cons.

チタンモリブデン合金粉 典型的な構成

| 合金グレード | Titanium (%) | Molybdenum (%) |

|---|---|---|

| Ti-6Al-7Nb (IMI 550) | バランス | 7% |

| Ti-15Mo-3Nb-3Al-0.2Si | バランス | 15% |

| Ti-11.5Mo-6Zr-4.5Sn (Ti-11) | バランス | 11.5% |

| Ti-15Mo-5Zr-3Al | バランス | 15% |

Molybdenum levels between 7% and 15% effective for high-temperature strengthening. Other elements like niobium, zirconium, and tin further boost creep properties.

特徴と特性

| 属性 | 詳細 |

|---|---|

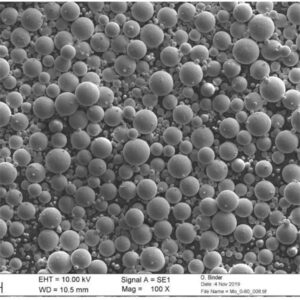

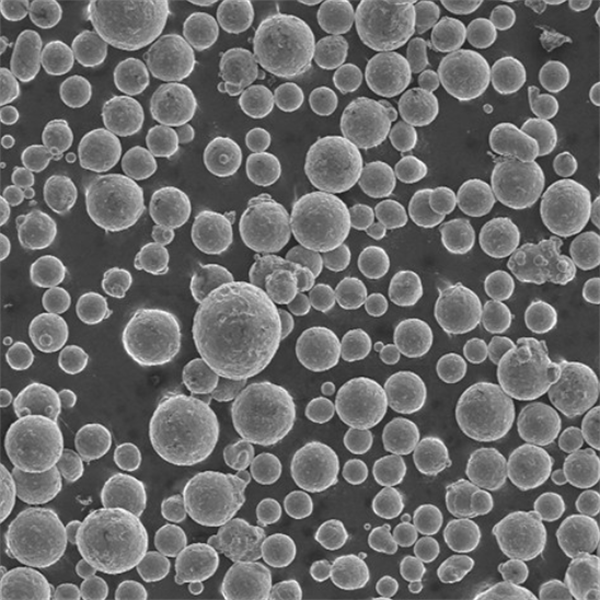

| 粒子形状 | Spherical from inert gas atomization |

| 酸素ppm | Below 500 ppm |

| Typical density | 4.5g/cc |

| 熱伝導率 | 4-6 W/mK |

| 高温強度 | 100 MPa at 500°C |

| 耐食性 | Forms protective TiO2 film |

Particulate nature, low oxygen content and tailored compositions suit alloy powder for additive manufacturing or sintering high performance components.

生産方法

| 方法 | プロセス説明 |

|---|---|

| ガス噴霧 | Inert gas disintegrates molten alloy stream into powder |

| プラズマ霧化 | Very clean but lower powder output vs gas atomization |

| 準備 | Spheroidization of existing powders by remelting |

| ヒドリド脱水素 | Brittle TiH2 intermediate for comminution |

Plasma and gas atomization offer the best quality while being more expensive vs secondary routes like PREP and HDH.

Applications of TiMo Alloy Powder

| 産業 | コンポーネント例 |

|---|---|

| 航空宇宙 | Turbine blades, casings, landing gears |

| 発電 | Heat exchangers, steam piping |

| 化学処理 | Bioreactors, reaction vessels |

| マリン | Propeller shafts, sonar domes |

| Oil and gas drilling | Geothermal well tools and shafts |

Combination of high strength, low weight and corrosion resistance suits TiMo alloys with demanding environments like aircraft engines or offshore drilling.

仕様

| スタンダード | 対象学年 |

|---|---|

| ASTM B862 | Ti-6Al-2Sn-4Zr-6Mo, Ti-8Al-1Mo-1V, Ti-6Al-2Nb-1Ta-0.8Mo |

| ASTM B348 | Titanium and titanium alloy bars and billets |

| AIMS 04-18 | Standard for AM titanium parts |

AMPM (American Powder Metallurgy) Institute, IPS (International Powder Metallurgy Standards Organization) also cover various Ti grades.

Global Suppliers and Price Range

| 会社概要 | リードタイム | 価格 |

|---|---|---|

| TLSテクニーク | 16 weeks | $300 – $900/kg |

| サンドビック | 12 weeks | $350 – $1000/kg |

| アトランティック・エクイップメント | 14 weeks | $320 – $850/kg |

Pricing for 100+ kg batch. Premium for low oxygen and spherical powder. Larger quantities above 500 kg offer 20%+ discounts.

長所と短所

| メリット | 課題 |

|---|---|

| 優れた高温強度 | High raw material costs |

| Corrosion resistant in many environments | Longer lead times for custom alloys |

| Custom alloy design flexibility | Limited global supply chain presently |

| Compatible with powder AM methods | Post-processing often needed after AM |

| 優れた耐クリープ性 | Stringent requirements on oxygen/nitrogen |

TiMo powders enable new component designs and lightweight construction but using titanium alloys poses unique powder manufacturing and handling challenges.

よくあるご質問

What particle size range is optimal for binder jet 3D printing?

Around 30 to 50 microns facilitates higher powder bed density and efficient liquid saturation needed to bind layers properly. Too fine powders hurt performance.

What causes contamination during Ti alloy gas atomization?

Oxygen pickup from any air leaks degrades powder purity hence the need for stringent process controls. Furnace parting agents and melt crucibles are other contamination sources requiring high purity consumables.

Why is high Mo content difficult to achieve in Ti based alloys?

Excessive evaporation losses of molybdenum occur above 25% levels during vacuum induction melting and subsequent remelting steps. Mitigation measures include covering melt pools or using cold crucible techniques.

How should titanium powder be stored?

Inside sealed containers under inert cover gas or vacuum. Handled and stored to exclude moisture absorption which causes decrepitation and high osyggen or nitrogen impurity.

What are common defects when AM printing titanium alloys?

Porosity from trapped gas atoms, lack of fusion defects, residual stress cracking, unfused powder trapped inside enclosed volumes. Require integrated parameters optimisation accounting for scan strategy, energy input etc.

結論

要約すると チタンモリブデン合金粉 provide customized high temperature properties and corrosion resistance vital for producing next generation components across aerospace, energy and other demanding industries via powder metallurgy or additive manufacturing.