With its high strength-to-weight ratio, temperature performance, corrosion resistance and durability, titanium is an exceptional material for additive manufacturing across critical commercial and industrial applications. Paired with the complex design freedoms facilitated by modern powder bed fusion approaches, チタンパウダー3Dプリンティング unlocks new potential.

This overview guide explores common titanium alloys leveraged, corresponding mechanical properties achieved, post-processing treatments to further enhance characteristics, available suppliers providing high purity print powders, and practical use case examples by end-use industry. Comparison tables highlight the relative strengths of different titanium materials and printing methods.

Overview of titanium powder 3d printing

Compared to conventional subtractive machining, additive printing using fine titanium metal powder feedstocks provides:

- Reduced Raw Material Waste – high buy-to-fly ratio over 90%

- Lower Component Mass – optimized lightweighting

- Design Freedom – complexity not limited by tool access

- Customization – site-specific feature tailoring

- Simplified Assemblies – integrated components

- Performance Improvements – stronger than cast and wrought

Both laser powder bed fusion and directed energy deposition (DED) techniques can successfully fabricate complex titanium parts. Quality assurance across the entire AM workflow – starting with high purity print powder – provides reliable, consistent high performance components.

Titanium Alloy Options for 3D Printing

The most common titanium material variants leveraged for additive applications include commercially pure grades and titanium 6Al-4V (Ti64). Emerging alloys like Ti6462 provide enhanced capability.

Standard Titanium Print Alloys Matrix

| 合金 | 構成 | プロパティ | 一般的な用途 |

|---|---|---|---|

| CPグレード1 | Ti 99.2%, Fe/O/N/C limits | Excellent corrosion resistance, average mechanicals | 化学プラント、海洋 |

| CPグレード2 | Ti 99.4%, Fe/O/N/C limits | Better strength than Gr1, equally corrosion resistant | Aerospace airframes, implants |

| Ti-6Al-4V | Ti 90%, Al 6%, V 4% | Harder, Excellent strength-to-weight ratio | Aerospace & motorsports |

| Ti6462 | Ti Bal, Al 5.8-6.8%, Mo 3% | High fatigue resistance. Aerospace spec under development | Next-gen aerospace components |

Trace elements like Fe, C, N and O are heavily controlled to meet strict chemistry requirements for AM.

仕様 チタンパウダー3Dプリンティング

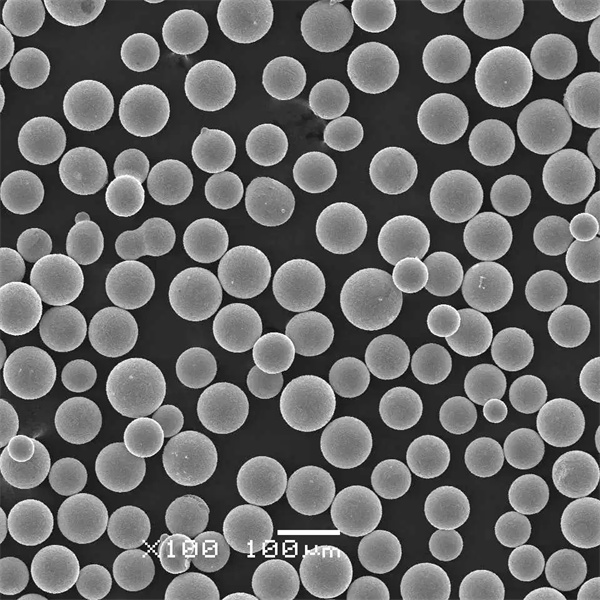

Spherical powders with controlled particle size distribution, minimal internal porosity and stringent chemistry purity levels are imperative for high quality printing using titanium.

Powder Feedstock Particle Standards

| 測定 | 必要条件 |

|---|---|

| サイズ範囲 | 15~53ミクロン |

| 平均粒子径 | 25-35 microns |

| 粒子形状 | Highly Spherical |

| 見かけ密度 | 2.7 – 3.7 g/cm3 |

| タップ密度 | 3.2 – 4.2 g/cm3 |

Standards tighten morphological parameters to improve powder bed packing and spreading behavior during printing cycles.

Post-Processing Methods for Titanium AM Parts

Common post-processing techniques applied to improve material performance of printed titanium-based components feature:

Primary Post-Treatments Used

応力緩和

Low temperature aging to remove residual stresses. Prevents potential warpage or cracking.

表面仕上げ

Enhances precision dimensions, breaks sharp edges or smooths exterior aesthetic appearance.

HIP(熱間静水圧プレス)

Simultaneous elevated temperature and isostatic pressure densifies internal voids/porosity present from AM processes.

熱処理

Alters microstructure of Ti-6Al-4V to optimize ductility, fracture toughness, and fatigue life.

機械加工

Brings extremely tight dimensional accuracy and surface finishes best addressed by CNC machining near-net shape parts.

Comparing Metal 3D Printing Techniques for Titanium

Modern techniques facilitate micro welding of fine titanium powder using precision laser melting or electron beams in tight inert environments:

Titanium Printing Process Options Matrix

| 方法 | 説明 | メリット | 制限事項 |

|---|---|---|---|

| レーザー粉体ベッド融合 | Laser selectively fuses regions of powder bed based on CAD model input | Highest commercial adoption; best fitness for final use material properties | Comparatively slower build speeds |

| 電子ビーム溶解 | Electron beam fuses powder spread across build plate in high vacuum | Exceptional consistency part-to-part; large potential build volumes | Challenging to process reactive elemental titanium without rigourous atmosphere controls |

| Direct Energy Deposition | Focused laser melts metal powder spray impacting the print area | Larger components feasible; repairs enabled | Significant porosity challenges titanium mechanical performance |

Laser-based powder bed approaches see predominant adoption for printing demanding titanium components thanks to precision dimensional accuracy and material purity.

Titanium Metal AM Part Applications

The tailorable mechanical properties, light-weightiness, corrosion and bio-inertness titanium provides over a wide temperature range suits nicely for:

Diverse Industries Adopting Titanium 3D Printing

航空宇宙 – Engine brackets, drone parts, satellite equipment Motorsports – Connecting rods, intake manifolds, turbochargers メディカル&デンタル – Custom orthopedic implants, prosthetics 石油・ガス – Pipeline fittings, deepwater valves/pumps 発電 – Lightweight impellors and turbine blades

Ability to manufacture complex low-volume components with advanced engineered metallurgy accelerates titanium adoption. Partnerships across the supply chain ensure material traceability and process repeatability.

Industrial Suppliers Providing チタンパウダー3Dプリンティング

Leaders providing high purity spherical titanium powders specifically for additive manufacturing processes feature:

Titanium Powder Producers Matrix

| 会社概要 | 共通グレード | Typical Pricing, $/Kg |

|---|---|---|

| エーピーアンドシー | Ti-6Al-4V, Gr2, Gr5, Ti6462 | $100 – $500 |

| LPWテクノロジー | Ti-6Al-4V, Gr23, Ti64 | $150 – $600 |

| テクナ | Ti-6Al-4V | $250 – $400 |

| サンドビック | Ti-6Al-4V | $200 – $350 |

Range on $/Kg basis depends significantly on purity, powder size distribution tightness, sampling, certifications required and purchase volumes. Local supply chain helps reduce lead times.

よくあるご質問

Which titanium alloy powder is considered optimal for medical devices & implants?

Due to its excellent biocompatibility paired with outstanding high cycle fatigue performance, medical grade 5 titanium per ASTM F67 meets stringent chemistry controls ideal for patient-facing devices and loadbearing implant applications.

How many times can titanium AM powder feedstocks be reused?

Titanium print powders may be effectively reused 5-10 times typically before refreshed, assuming strict monitoring protocols over acceptable oxygen pickup levels from repeated thermal cycling are maintained below maximum thresholds through blending and sieving.

What density should be expected for laser-melted titanium parts without any post-processing?

Directly after removal from a powder bed system with optimized processing parameters, near-full densities over 98% should be expected for as-built titanium components, rivaling and exceeding cast or wrought products requiring extensive downstream operations to achieve similar performance.

What post-processing technique boosts fatigue life the most?

For prominent Ti-6Al-4V alloy parts seeing cyclic stresses, Hot Isostatic Pressing (HIP) provides up to ~30% longer fatigue lifespans by minimizing internal voids and residual porosity typically present after metal AM processes from unavoidable localized micro shrinkage effects between fused powder particles.

Outside directed energy deposition techniques what other surface enhancement methods successfully modify titanium AM parts?

Thermal spray technologies like plasma transferred arc (PTA), high velocity air fuel (HVAF), and high velocity oxygen fuel (HVOF) welding techniques allow thick protective exterior coatings including ceramics; cold spray impacts powders onto surfaces providing thickened sections and wear protections; laser cladding or laser metal deposition overlay additional metal alloys enhancing corrosion, friction and impact resistance through superior metallurgical bonding.