チタン粉 is a versatile metal powder with unique properties that make it ideal for a wide range of applications across industries like aerospace, medical, automotive, and more. This article provides a comprehensive overview of titanium powder along with details on types, composition, properties, applications, specifications, pricing, pros and cons, and leading global suppliers.

概要 titanium powder suppliers

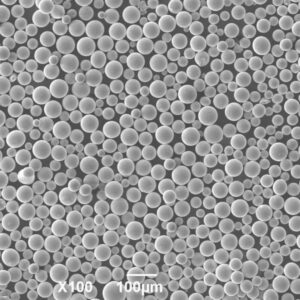

Titanium powder is composed of titanium metal particles in powder form produced by various methods like gas atomization, plasma atomization, and hydride-dehydride process. The particles vary in size and shape based on production technique but generally range from 10 microns to 250 microns.

Titanium powder offers excellent strength-to-weight ratio, fatigue and corrosion resistance, biocompatibility, high melting point, and ability to withstand extreme temperatures. Key properties that make titanium powder suitable for high performance applications are summarized below:

| プロパティ | 説明 |

|---|---|

| 高強度 | Offers very good tensile and compressive strength for its weight. Stronger than aluminum. |

| 軽量 | Almost half the density of steel and superalloys. Reduces component weight. |

| 耐食性 | Forms protective oxide layer in air. Resists corrosion in harsh environments. |

| 生体適合性 | Non-toxic and compatible with human body tissues and bones. |

| High temperature | Melting point of 1668°C. Retains properties at high operating temps. |

| 熱特性 | Low thermal conductivity. Good heat and thermal shock resistance. |

| 非磁性 | Useful where magnetic materials cause interference. |

The combination of these properties allow titanium powder to outperform competing materials like aluminum, magnesium, or steel alloys in the most demanding applications while still remaining cost-effective.

Types of titanium powder suppliers

Titanium powder is available in different compositions, sizes, morphologies, and purity levels to suit specific application requirements in various industries.

By Composition:

- Pure Titanium Powder: 99% or higher titanium content.

- Titanium Alloys: Titanium mixed with aluminum, vanadium, iron, molybdenum etc.

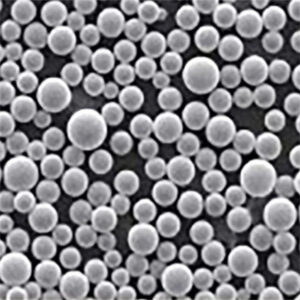

By Particle Size:

- Fine Powder: 10 to 45 microns

- Coarse Powder: Up to 150 microns

- Ultrafine Powder: 5 microns and under

By Particle Shape:

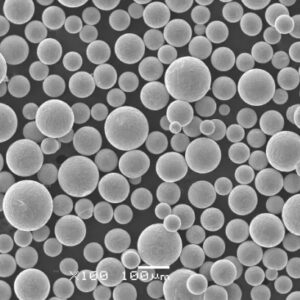

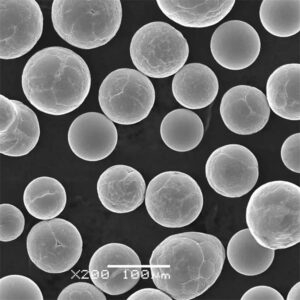

- Spherical Titanium Powder

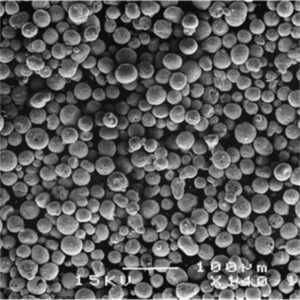

- Angular / Irregular Titanium Powder

By Manufacturing Method:

- Gas Atomized Titanium Powder

- Plasma Atomized Titanium Powder

- Hydride-Dehydride Titanium Powder

By Purity Levels:

- Grade 1: 99.5% Titanium

- Grade 2: 99.5% Titanium, Low Oxygen

- Grade 3/4: 97.75% Titanium

- Grade 5: 97% Titanium, High Oxygen

Each type has specific characteristics that make it suitable for certain titanium powder applications over others. Customization of composition, size, shape, production method, and purity helps achieve the desired powder properties.

組成と特性

Titanium powder can be pure titanium or titanium alloys with other elements like aluminum, vanadium, iron, and molybdenum added. This affects the material properties and performance.

チタン粉末の組成

| エレメント | 組成範囲 |

|---|---|

| チタン(Ti) | バランス |

| アルミニウム(Al) | 2% – 7% |

| バナジウム (V) | 2% – 20% |

| 鉄(Fe) | 0.3% – 0.8% |

| 酸素 (O) | 0.08% – 0.5% |

| カーボン(C) | 0% – 0.15% |

| 窒素(N) | 0% – 0.05% |

- Pure titanium offers the highest tensile strength and low weight.

- Aluminum stabilizes the alpha phase in titanium leading to increased strength.

- Vanadium strengthens titanium and reduces weight loss at high operating temps.

- Small amounts of iron impart ductility during metal working.

- Trace oxygen improves powder flow characteristics.

Effect of Composition on Properties

| プロパティ | 純チタン | チタン合金 |

|---|---|---|

| 密度 | 低い | Higher than pure titanium |

| 引張強さ | 高い | 非常に高い |

| 硬さ | ミディアム | 高い |

| 延性 | 高い | 中~高 |

| Operating temp | Up to 600°C | Up to 800°C |

| 耐食性 | 素晴らしい | グッド |

| コスト | より高い | より低い |

The right composition tailors the titanium powder properties like strength, temperature resistance, weight, ductility, and cost. Titanium alloys offer the best balance across critical performance parameters.

の応用 titanium powder suppliers

The unique properties of titanium powder make it suitable for critical applications across aerospace, automotive, medical, chemical, and other general engineering industries.

航空宇宙 Aircraft engine and structural components like compressor blades, discs, shafts, gears, nacelles, fasteners, pipes etc. due to high specific strength.

自動車: Connecting rods, valves, turbocharger rotors, and parts needing weight savings with reliability.

メディカルだ: Surgical instruments, implants like knee and hip joints, pacemakers, pins, screws owing to biocompatibility and corrosion resistance.

Chemical: Equipment like heat exchangers, tanks, pipes, pumps, valves handle corrosive environments at high temperature enabled by titanium.

General Engineering: Sporting goods like golf clubs, bicycle parts, marine applications utilize titanium’s strength and stiffness.

Other miscellaneous applications are found in fasteners, welding wire, additive manufacturing powders, catalysts etc across industries.

In many critical components, titanium powder is increasingly the material of choice over stainless steel and nickel alloys due to performance benefits.

Specifications of titanium powder suppliers

Titanium powder is available under established specifications that define properties in terms of particle size distribution, morphology, flow rate, purity levels, alloy composition etc. that influence application suitability.

粒度分布

| ミクロン | Percentage Under |

|---|---|

| 45 | 100% |

| 25 | 98% |

| 15 | 75% |

- Narrow distribution ensures uniformity in part properties.

- Typical range is 10 to 150 microns based on application.

- Controlled by precise gas atomization process parameters.

粒子の形態学

| プロパティ | 仕様 |

|---|---|

| 粒子形状 | 主に球形 |

| 衛星粒子 | Under 5% |

| Gases and inclusions | 最小限 |

- Spherical morphology ensures good density and powder flow.

- Low satellite particles reduce entrapment issues during compaction.

- Purity checked by optical microscopy and spectrometry.

流量

| 方法 | Spec Limit |

|---|---|

| ホール流量計テスト | > 28 sec for 50 grams |

| ASTM B213 | Flow rate of ≥ 25 s/50 g |

- Good flow and packing density allows automated handling.

- Ensures less variation during volume production.

Composition and Impurities

| グレード | Tiコンテンツ | Key Impurities |

|---|---|---|

| グレード1 | ≥ 99.5% | Fe, C, H, N, O |

| グレード2 | ≥ 99.5% | O |

| グレード5 | ≥ 97% | Fe, C, H, N, O |

- Higher titanium purity improves performance properties.

- Limits defined for trace elements based on application.

- Verified by industry accepted test methods.

Many other application-based physical, chemical and microstructure properties may be specified by end users regarding crystal structure, density, yield strength, corrosion rates etc.

Global titanium powder suppliers

Titanium powder production involves specialized equipment and processes necessitating dedicated metal powder producers across geographies. The complex methods also lead to significant quality variations across manufacturers.

The top global titanium powder suppliers known for capacity, quality, costs, and industry expertise are given below:

Leading Titanium Powder Companies

| 会社概要 | 国名 | 生産能力 |

|---|---|---|

| ATI粉末冶金 | アメリカ | 5400 tons per year |

| テクナ | カナダ | 2000 tons per year |

| TLSテクニーク | ドイツ | 4800 tons per year |

| エーピーアンドシー | カナダ | 7000 tons per year |

| CRISTAL | フランス | 8000 tons per year |

| OSAKA Titanium | 日本 | 4500 tons per year |

These prominent manufacturers have the latest atomization technologies, stringent quality control infrastructure, and decades of powder metals expertise geared towards high end applications. They can customize titanium powder compositions and properties working closely with clients.

Besides these large producers, many smaller regional titanium powder suppliers also exist catering to local markets across Americas, Asia Pacific, and EMEA regions. However quality, consistency and performance parameters may show more variability.

titanium powder Pricing

- Titanium powder is more expensive than competing metal powders like aluminum, iron, nickel etc. owing to complex manufacturing and raw material costs. Prices depend on:

Determining Cost Factors

| ファクター | 説明 |

|---|---|

| 純度 | Increases exponentially above 98% titanium content |

| 粒子径 | Ultrafine below 10 microns is costlier |

| 注文量 | Large bulk orders get discounted rates |

| 合金元素 | Each addition increases pricing |

| 地域 | US and Europe command premium over Asia |

- For example spherical Ti-6Al-4V ELI powder with -45 micron size for medical application can cost $100+ per kg compared to $20 per kg for stainless steel powder.

- However titanium becomes cost competitive when lifecycle costs like fuel savings, reduced maintenance etc. are considered against alternative materials.

Titanium Powder Price Ranges

| 申し込み | kgあたりの価格 |

|---|---|

| 航空宇宙 | $70 – $150 |

| メディカル | $80 – $250 |

| 自動車 | $50 – $100 |

| 積層造形 | $100 – $300 |

| その他 | $40 – $120 |

Pricing also varies across manufacturers based on quality, production technology, testing standards and batch traceability followed. Selecting the right supplier that balances price, performance and consistency is key to maintaining part quality and costs.

How to Select Titanium Powder Suppliers

Choosing titanium powder suppliers entails evaluating several parameters across quality, consistency, pricing and service to find the optimal balance for the application.

Key Selection Criteria

| パラメータ | Checks |

|---|---|

| パウダー仕様 | Size distribution, morphology, flow rate etc. as per application standards |

| 構成 | Alloy grade, % titanium, impurities etc. match component design |

| Consistent properties | Multiple batch testing data for particle size, density, morphology etc. |

| 品質認証 | ISO 9001, AS 9100, ISO 13485 based on end use |

| 試験能力 | In-house lab for comprehensive physical and chemical testing |

| Control standards | Traceability for complete production history and parameters |

| Post-sales service | Technical support for powder handling, storage, defects etc. |

| 価格 | Quoted rate analysis including surcharges, minimums etc. |

| 配送 | Lead time, shipment lots and logistics reliability |

- Samples should be procured to conduct trial runs simulating real component manufacturing.

- Site audits of production facilities is highly recommended for strict aerospace & medical applications.

This comprehensive evaluation helps determine if the titanium powder producer has the experience, expertise and infrastructure to deliver the right powder quality over long production cycles demanded by end applications.

チタン粉末の長所と短所

Titanium powder offers many advantages but also comes with a few limitations that must be considered for optimal materials selection.

長所

- 高い強度重量比

- Retains mechanical properties at elevated temperatures

- 優れた耐食性

- 医療用インプラントの生体適合性

- 高い硬度と耐摩耗性

- 低い熱伝導率

- 非毒性、非アレルギー性

- Non-magnetic enabling precision instruments

短所

- Expensive compared to steel, aluminum powders

- Chemically reactive with oxygen at high temperatures

- Difficult to machine requiring non-ferrous tooling

- Requires controlled cooling and inert atmosphere processing

- Limited number of qualified titanium powder suppliers

- Susceptible to contamination causing hydrogen embrittlement

Understanding these key advantages versus limitations helps determine if titanium powder is the right fit or if alternatives like aluminum alloys or stainless steel may serve the application better in terms of technical performance or commercial viability. Cross-functional inputs across design, production and quality teams are essential.

よくあるご質問

Q. What are the different manufacturing methods for titanium powder?

Titanium powder can be produced via gas atomization, plasma atomization, or hydride-dehydride process. Gas atomized powder offers the most spherical morphology preferred for additive manufacturing whereas plasma atomized powder achieves finer sizes.

Q. What particle size is typically used for 3D printing applications?

For most binder-jet and laser powder bed fusion 3D printing, titanium powder between 10 to 45 microns with narrow distribution is recommended by most printer manufacturers to achieve good powder flow and spreadability along with layered fusion.

Q. Which industries use titanium powder for components?

Titanium is used to make high performance components via metal injection molding, hot isostatic pressing, additive manufacturing etc. across aerospace, medical technology, automotive, chemicals, oil and gas, sports equipment, and general engineering.

Q. Does titanium powder require special storage or handling precautions?

Titanium reacts easily with air moisture and oils. So it must be stored in sealed containers under inert argon or nitrogen atmosphere with controlled humidity levels to prevent contamination issues leading to poor material properties.

Q. Where can I find titanium powder suppliers in my country?

The major global titanium powder producers have local sales offices and distributors across most regions in the Americas, Europe and Asia-Pacific. They can guide buyers find the closest supply points for small to large quantities based on application requirements and shipping costs optimization.