チタンTi64ELIパウダーは、そのユニークな特性と特徴のために様々な産業で使用される重要なエンジニアリング材料です。この記事では、チタンTi64ELI粉末の組成、特性、用途、仕様、価格、利点、および制限をカバーする包括的な技術的概要を提供します。

Overview of Titanium Ti64ELI Powder

Titanium Ti64ELI powder, also known as Titanium 6Al-4V ELI powder, is a titanium alloy containing aluminum and vanadium as alloying elements. It has excellent strength-to-weight ratio, fatigue resistance, fracture toughness, and corrosion resistance. Ti64ELI powder is the extra-low interstitial variant of Ti64 with lower levels of oxygen, nitrogen, carbon, and iron.

Ti64ELI is used for additive manufacturing, metal injection molding, hot and cold isostatic pressing, and other powder metallurgy processes. It can be 3D printed into fully dense, complex parts with fine microstructures and mechanical properties comparable to wrought Ti64 products. Ti64ELI’s combination of light weight, strength, and corrosion resistance make it suitable for aerospace, medical, dental, sporting goods, automotive, and marine applications.

Some key features of Titanium Ti64ELI powder include:

- 優れた生体適合性とオッセオインテグレーション

- Ability to 3D print intricate geometries not possible with casting/machining

- Consistent composition and microstructure in 3D printed parts

- 優れた疲労強度と破壊靱性

- Lower interstitial elements than Ti64 for superior ductility

- Compatibility with hot isostatic pressing (HIP) and heat treatments

- Conformance to ASTM standards for chemistry and particle size

Composition of Titanium Ti64ELI Powder

The typical chemical composition of titanium Ti64ELI powder is:

| エレメント | 重量 % |

|---|---|

| チタン(Ti) | バランス |

| アルミニウム(Al) | 5.5-6.75% |

| バナジウム (V) | 3.5-4.5% |

| 酸素 (O) | ≤ 0.13% |

| 窒素(N) | ≤ 0.05% |

| カーボン(C) | ≤ 0.08% |

| 鉄(Fe) | ≤ 0.25% |

The key alloying elements are aluminum and vanadium. Aluminum increases strength and decreases density. Vanadium improves strength and ductility. The low interstitial elements oxygen, nitrogen and carbon in Ti64ELI give it better ductility compared to Ti64.

Properties of Titanium Ti64ELI Powder

Titanium Ti64ELI powder has the following properties:

| プロパティ | 価値 |

|---|---|

| 密度 | 4.43 g/cm3 |

| 融点 | 1604-1660°C |

| 熱伝導率 | 6.7 W/m-K |

| 電気抵抗率 | 170 μΩ-cm |

| ヤング率 | 114 GPa |

| 引張強度 | 895-930 MPa |

| 降伏強度 | 825-875 MPa |

| 伸び | 10-15% |

| ポアソン比 | 0.32-0.34 |

| 疲労強度 | 400MPa |

Key highlights:

- 鋼鉄に比べて密度が低い

- 極低温でも強度と靭性を保持

- Stronger than commercially pure titanium

- Lower ductility than wrought Ti64 but sufficient for most applications

- Excellent corrosion resistance due to stable protective oxide layer

Applications of Titanium Ti64ELI Powder

Titanium Ti64ELI powder is used to manufacture parts for the following applications:

航空宇宙 Engine components, airframes, turbines, fasteners, gears, hydraulic systems

医療と歯科: Orthopedic implants, prosthetics, surgical instruments, dental implants

自動車: Valves, connecting rods, racing car components

Marine: Propellers, pumps, shafts, pipes, fittings

Chemical: Heat exchangers, valves, pipes for handling corrosive chemicals

Sporting Goods: Golf clubs, bicycle frames, tennis rackets, lacrosse sticks

アディティブ・マニュファクチャリング 3D printed parts for aerospace, automotive, and medical sectors

Ti64ELI is preferred over Ti64 in AM due to lower interstitial elements that cause embrittlement in 3D printed Ti64 parts. It also has high biocompatibility for medical implants.

Specifications of Titanium Ti64ELI Powder

Titanium Ti64ELI powder is available in the following specifications:

| パラメータ | 詳細 |

|---|---|

| 粒子サイズ | 15-45ミクロン |

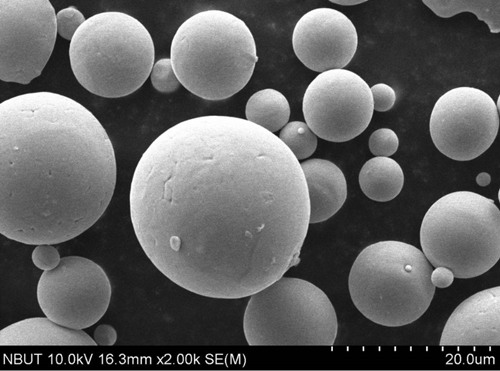

| 製造方法 | ガス噴霧 |

| 粒子形状 | 球形 |

| サイズ分布 | D10: 20 microns, D50: 35 microns, D90: 40 microns |

| 見かけ密度 | ~2.2 g/cc |

| タップ密度 | ~3.2 g/cc |

| 流動性 | 素晴らしい |

| 規格 | ASTM B348 Grade 23 |

Larger particle sizes of 63-106 microns can be custom produced based on application requirements. Finer particle sizes are available for metal injection molding feedstock.

Suppliers and Pricing of Titanium Ti64ELI Powder

Some of the major suppliers and pricing details for titanium Ti64ELI powder include:

| サプライヤー | 価格 |

|---|---|

| エーピーアンドシー | $88/kg for orders >1000 kg |

| アルカムAB | $75/kg for orders >500 kg |

| TLSテクニーク | €100/kg for orders >100 kg |

| LPWテクノロジー | £70-90/kg for orders >100 kg |

| CNPCパウダー | $80-100/kg for >100 kg |

Prices vary from $70-100 per kg based on order quantity, particle size distribution, and location. Small quantity and research samples can cost over $500/kg.

Comparison Between Titanium Ti64 and Ti64ELI Powders

Here is a comparison between Ti64ELI and Ti64 titanium alloys:

| パラメータ | Ti64ELI | Ti64 |

|---|---|---|

| Interstitial O, C, N | より低い | より高い |

| 延性 | より高い | より低い |

| タフネス | より良い | 貧しい |

| 溶接性 | 素晴らしい | 中程度 |

| 耐食性 | 比較可能 | 比較可能 |

| 強さ | 比較可能 | 比較可能 |

| コスト | より高い | より低い |

| AM suitability | 素晴らしい | 中程度 |

Advantages of Ti64ELI over Ti64:

- より優れた延性と破壊靭性

- Lower tendency to crack during additive manufacturing

- Can be heat treated to higher strength levels

- More resistant to hydrogen absorption and embrittlement

Limitations of Ti64ELI vs Ti64:

- Higher cost due to raw material purity and processing

- Not recommended for high temperature applications over 300°C

- Less alloy development data available compared to Ti64

Pros and Cons of Titanium Ti64ELI Powder

メリット

- 優れた強度対重量比

- Bio-inertness allows use for medical implants

- Withstands sterilization and autoclaving

- 過酷な環境でも腐食に強い

- Compatible with traditional and additive processes

- Heat treatable to tailor properties

- Can be plated for aesthetics and bonding

デメリット

- More expensive than stainless steels and aluminum alloys

- Lower stiffness than steel, prone to springback

- Poor shear strength compared to steels

- Titanium dust poses fire hazard

- Difficult to machine due to low thermal conductivity

- Susceptible to galling and seizing during machining

- Surface treatments mandatory for adhesive bonding

- Requires inert gas shielding during AM and welding

よくあるご質問

Q: What is the difference between Ti64ELI and Ti64?

A: Ti64ELI has lower interstitial oxygen, nitrogen and carbon compared to Ti64. This gives Ti64ELI better ductility and fracture toughness.

Q: What are the applications of Ti64ELI powder?

A: Key applications are aerospace components, medical implants, automotive parts, and 3D printing. It is widely used in industries where high strength, low weight and corrosion resistance are required.

Q: What particle size is used for AM?

A: Particle sizes of 15-45 microns are recommended for powder bed fusion AM processes like selective laser melting (SLM) and electron beam melting (EBM).

Q: What are the advantages of Ti64ELI over stainless steel?

A: Ti64ELI has higher strength-to-weight ratio, better corrosion resistance, and superior biocompatibility compared to stainless steels. However, Ti64ELI is also more expensive.

Q: What post-processing is required on Ti64ELI AM parts?

A: AM parts may need hot isostatic pressing (HIP), heat treatments, and machining to achieve the required dimensions, surface finish, and material properties.

Q: Can Ti64ELI parts be welded for repair or joining?

A: Yes, Ti64ELI has excellent weldability. Laser welding, electron beam welding, and arc welding can be used to weld Ti64ELI parts. Proper shielding is necessary to prevent oxidation.

結論

In summary, titanium Ti64ELI powder offers an excellent combination of high strength, low weight, corrosion resistance, biocompatibility, processability, and heat treatability. Its applications span aerospace, medical, automotive, chemical, and consumer sectors. With additive manufacturing, complex Ti64ELI parts can be 3D printed directly from CAD data for on-demand production of lightweight structural components. However, Ti64ELI is costlier than Ti64 and challenging to machine. Overall, Ti64ELI presents capabilities beyond the limits of conventional titanium alloys.