MIM Metal Powder (MIM) is an efficient manufacturing process that combines the design flexibility of plastic injection molding with the strength and properties of machined metal parts. The key material for MIM is metal powder, specifically tailored for this process. This guide provides a comprehensive overview of MIM metal powder including composition, production, properties, applications, and more.

概要 MIMメタルパウダー

MIM metal powder refers to fine metal powders used as feedstock for the metal injection molding process. It is a mixture of fine metal powder and binder that is injected into molds to form complex, net-shape green parts.

Key features of MIM powder include:

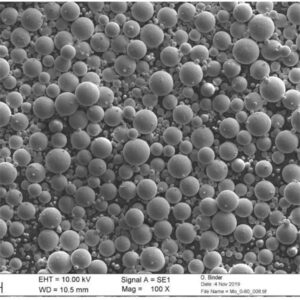

- Ultrafine spherical powder 10-20 microns in size

- Powder loading of 55-65% by volume in binder

- Excellent flowability for mold filling

- 一貫した粒度分布

- Alloy compositions optimized for MIM

- Wide range of material options like steels, stainless steels, titanium alloys, tungsten heavy alloys, etc.

- Cost-effective production of complex, tight tolerance metal components

The global MIM powder market was over $350 million in 2020. The industry is projected to grow steadily at over 8% CAGR driven by demand across diverse sectors.

Types of MIM Metal Powder

Various metal powder compositions are used for MIM feedstock. The most common types include:

| 素材 | 主要物件 | アプリケーション |

|---|---|---|

| ステンレス鋼 | 耐食性、強度 | Medical, automotive, consumer products |

| 工具鋼 | 高硬度、耐摩耗性 | Cutting tools, dies, gears |

| Low alloy steels | Magnetic properties, machinability | Electromechanical components |

| チタン合金 | 高い強度対重量比 | Aerospace, military, biomedical |

| タングステン重合金 | Density, vibration damping | Automotive, sports equipment |

| 超合金 | 高温強度 | Turbine and rocket components |

By selecting appropriate powder metal alloys, components can be fabricated with properties tailored for specific applications.

Production of MIM Metal Powder

Several methods are used commercially to produce fine metal powders for MIM feedstock:

ガス噴霧 – High velocity inert gas jets break up a thin stream of molten metal into fine droplets that solidify into spherical powders ideal for MIM. Common for steels, superalloys, and non-ferrous alloys.

水の霧化 – Similar to gas atomization but lower cooling rate produces more irregular powder shapes suitable for some applications. Lower cost process used for common alloys like iron, copper.

プラズマ霧化 – Extremely high temperature plasma arc used to generate finer spherical powders from reactive alloys like titanium, niobium, and tantalum.

Mechanical Attrition – Ball milling is used to reduce the particle sizes of metal powder blends to the MIM range. Efficient dry process.

カルボニルプロセス – Iron and nickel carbonyls are decomposed to produce high purity spherical powders of 1-5 microns particle size.

The powder making method controls final powder characteristics like flowability, tap density, and impurities.

の性質 MIMメタルパウダー

Key properties of MIM feedstock powder include:

粒子径 – Between 1 to 20 microns, typically around 10 microns for optimal filling. High yields in this range.

粒子形状 – Predominantly spherical morphology allows smooth flow into complex molds. Some irregularity acceptable.

粒度分布 – Narrow distribution improves uniform sintering. Generally 80-90% of particles within 10 +/- 5 microns range.

タップ密度 – Indicates final part density. Higher tap density above 3 g/cc needed for high mechanical properties.

流量 – Measured in seconds/50g. Critical for smooth mold filling without gaps. Below 40 s/50g desirable.

見かけ密度 – In feedstock, typically 40-50% of final sintered density indicating powder loading fraction.

Pycnometric density – Actual density of the solid alloy particles. Matching with final part density indicates purity.

比表面積 – High values indicate finer particle size distribution desirable for MIM. Ranges from 0.1 to 1 m2/g.

Alloy Options for MIM Metal Powder

A wide range of alloys are available as MIM powder feedstock, including:

| 合金 | 構成 | プロパティ | アプリケーション |

|---|---|---|---|

| ステンレス 316L | Cr、Ni、Mo | 優れた耐食性 | Medical, food contact |

| ステンレス鋼 17-4PH | Cr、Ni、Cu | High strength, hardness | 航空宇宙部品 |

| Tool steel H13 | Cr, Mo, V | Hot hardness, thermal fatigue resistance | 射出成形 |

| Maraging steel | Ni, Co, Mo, Ti | 超高強度 | Aerospace, tooling |

| Alloy steel | Cr, Mo, C | Heat treatable, magnetic | 構造部品 |

| Nickel alloy 718 | Ni, Fe, Nb, Mo | 高温強度 | 航空宇宙 |

| チタン Ti-6Al-4V | Ti、Al、V | Lightweight, biocompatibility | 医療用インプラント |

| Tungsten heavy alloy | W, Ni, Fe | High density, radiation shielding | Military, motorsports |

With a broad range of alloys available, MIM provides flexibility in achieving required material properties and performance.

Applications of MIM Metal Powder

The major application areas using MIM technology and feedstock powder include:

Medical and Dental Implants

MIM is ideal for high volume production of small, complex stainless steel and titanium implant components like joints, fixation screws, instruments. Offers biocompatibility, corrosion resistance, strength, and manufacturing precision.

Automotive Components

Small precision parts like turbocharger rotors, injector nozzles, valve locking caps made by MIM provide performance benefits in modern engines and powertrains.

コンシューマー・エレクトロニクス

Miniature components like watch gears, decorative fittings, connector pins etc. are manufactured via MIM from stainless steels, copper alloys and tool steels.

Aerospace and Defense

Lightweight, high strength Ti and Ni alloys MIM components reduce weight in turbines and airframes. Tungsten alloys offer radiation shielding for space and defense uses.

銃器

Small, complex firearm components like triggers, hammers, safeties, ejectors can be MIM fabricated in high volumes from stainless steels and tool steel alloys.

Watch Industry

MIM enables economical production of intricately shaped stainless steel watch cases, bracelets, buckles and miniature moving components like gears and springs.

With its design flexibility, MIM continues finding applications across diverse sectors from consumer products to critical industrial components.

How to Choose MIMメタルパウダー

Key considerations when selecting MIM feedstock powder:

- 合金組成 – Match powder alloy to end application requirements like corrosion resistance, strength, wear properties etc.

- 粒子の大きさと形状 – Prefer spherical morphology with narrow distribution around 10 microns for optimal flow and packing.

- Powder purity – High purity above 99% needed for specialized applications like medical to avoid contamination.

- タップ密度 – Higher density above 3 g/cc improves mold filling and final part density after sintering.

- パウダーローディング – Binder content between 30-50 vol% is typical. Affects viscosity and molded green strength.

- Powder producer – Reputable powder makers like Sandvik, BASF, and Kymera with validated processes.

- Lot-to-lot consistency – Consistent feedstock properties allow stable molding parameters over long production runs.

- テクニカルサポート – Detailed application data and assistance from the powder supplier during development trials.

Leading global suppliers include Sandvik Osprey, BASF Ultraform, Kymera International, and Epson Atmix who collaborate with end-users during part and process development for optimum results.

Comparison Between Atomized and milled MIM Powders

| パラメータ | Atomized Powders | Mechanically Milled Powders |

|---|---|---|

| 粒子形状 | 球形 | 不規則、角張っている |

| サイズ範囲 | 1 – 20 microns | 10 – 100+ microns |

| サイズ分布 | Very narrow | Broad |

| タップ密度 | Higher ~3-4 g/cc | Lower ~2-3 g/cc |

| 流量 | 素晴らしい | 中程度 |

| 純度 | 高い | より低い |

| コスト | より高い | より低い |

| Alloys available | Most standard and specialty alloys | 限定合金 |

| アプリケーション | Most MIM components | Larger, less critical MIM parts |

Atomized powders allow more complex, higher performance MIM components. Milled powders offer a cost saving option for some applications.

Installation of a MIM Powder Production Plant

Key steps in installing a MIM powder production plant:

- Site selection – Adequate space, utilities supply, waste handling, access roads and loading bays.

- Building and layout – Design plant layout for material and people flow, safety, production zones, future expansion.

- Utility connections – High capacity electrical supply, purified water, compressed air lines, liquid nitrogen.

- Machinery foundations – Strong reinforced concrete foundations for atomizers, mills, furnaces. Vibration dampening.

- Equipment installation – Set up glove boxes, atomizers, sieves, conveyors, hoppers, controls per supplier instructions.

- Auxiliary systems – Piping, ventilation, air filtration, fire safety, material handling, waste water treatment.

- 制御システム – Install sensors, actuators, HMIs. Integrate and program process control systems.

- コミッショニング – Test production runs to verify powder quality, safety, environmental compliance before full scale production.

MIM powder plant installation requires extensive planning and attention to utilities, controls, safety, and regulatory needs.

Operation and Maintenance of MIM Powder Equipment

Reliable operation of MIM powder manufacturing equipment requires:

- Preventive maintenance – Schedule periodic maintenance of atomizers, furnaces, mills, conveyors as per OEM recommendations .

- Equipment monitoring – Continuous monitoring of process parameters like flow, pressure, temperature, power consumption.

- 検査 – Daily visual inspections for leaks, abnormal noises or vibration, safety issues.

- Services and repairs – Schedule annual service contracts for nitrogen generators, chiller units, electrical systems.

- Spare parts – Keep stock of common spares like heating elements, motors, bearings to minimize downtime.

- Equipment logs – Maintain logs for production rate, repairs, breakdowns to optimize asset utilization.

- ハウスキーピング – Daily cleaning to maintain clean, orderly equipment and avoid any ignition risks in powder handling areas.

- Staff training – Conduct hands-on equipment training to improve operational efficiency and troubleshooting skills.

With excellent maintenance practices, MIM powder making equipment can deliver years of safe, reliable production.

How to Select a MIM Powder Supplier

Key factors when selecting a MIM powder supplier:

- 技術的専門知識 in powders – Experience optimizing powder characteristics and binder formulation for MIM.

- Range of alloys – Availability of wide variety of alloys from stainless steels to titanium, tool steels etc.

- 品質システム – ISO 9001 certification. Internal quality control of powder characteristics.

- 一貫性 – Powder properties remain consistent batch-to-batch allowing stable molding process.

- 研究開発能力 – Continuous research to develop new tailored alloys and binders for demanding applications.

- カスタマーサービス – Responsive technical and sales support. On-site assistance during trials and ramp-up.

- Logistics capability – Systems to ensure efficient, on-time powder deliveries across regions.

Leading global suppliers include Sandvik Osprey, BASF, Kymera International, and Epson Atmix who are highly focused on MIM powder technology.

Pros and Cons of MIM Powder

長所

- Complex, net shape parts in high volumes at low costs

- Wide range of alloys available including difficult to machine metals

- Good mechanical properties close to wrought materials

- High accuracy and repeatability

- Minimal scrap losses compared to machining

- Limited finishing required on sintered parts

- Environmentally cleaner process with less waste than machining

短所

- Higher part cost for lower production volumes

- Size limited to smaller components, typically below 500 g

- Restricted to alloys available as MIM powder blends

- Sintered parts have lower ductility than wrought metals

- Specialized equipment and expertise needed

- Additional debinding and sintering steps

MIM Powder vs. Metal Powders for Other Applications

| パラメータ | MIMパウダー | 積層造形パウダー | Press and Sinter Powder |

|---|---|---|---|

| 合金 | Wide range of stainless, tool steels, Ti alloys | Limited alloys like 17-4PH, Ti-6Al-4V, CoCr | Low alloy and stainless steels |

| 粒子形状 | 主に球形 | 球形度が高い | Irregular acceptable |

| サイズ範囲 | 1-20 microns | 15-45ミクロン | Up to 150 microns |

| サイズ分布 | Very narrow | Narrow | Wider acceptable |

| 純度 | 中~高 | 高い | ミディアム |

| コスト | ミディアム | 高い | 低い |

| Typical production method | ガスまたは水の霧化 | Gas or plasma atomization | Water atomization, mechanical milling |

よくあるご質問

Q: What is the typical size distribution of MIM powder?

A: Around 80-90% of MIM powder particles fall within 10 +/- 5 microns for optimal packing density and flow.

Q: What factors affect powder loading in the binder?

A: Key factors controlling powder loading % are particle size distribution, shape, tap density, and powder-binder interaction.

Q: How is high temperature strength of MIM parts compared to wrought alloys?

A: With optimal sintering, MIM parts in alloys like stainless steel 316L and 17-4PH achieve over 90% of wrought strength.

Q: What causes incomplete mold filling defects in MIM?

A: Improper powder loading, wide particle distribution, poor powder flowability, and low injection velocity can cause filling defects.

Q: How does MIM compare to plastic injection molding in terms of molding pressures?

A: MIM injection pressures range from 70-140 MPa, higher than typical plastic molding pressures of 15-60 MPa.

Q: What safety precautions are required when handling MIM powders?

A: MIM powders can be flammable. Use inert gas glove boxes, avoid spark sources, ground equipment, and use dust extraction.

結論

MIM continues to grow in prominence as a near net shape technology to manufacture high performance, complex metal components at low cost and high volumes. MIM powders are critical raw materials formulated specifically for this process by advanced powder metallurgy techniques. With expanded alloys and improved powders, MIM adoption will continue rising across industries to replace machined and cast components with improved cost and lead time.